Material distribution method and system for production of canyon lava flow layer imitation ceramic tile

A technology of rock flow layer and ceramic tiles, which is applied in the field of ceramic tile manufacturing, to achieve the effect of natural and soft patterns, rich patterns and vivid textures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

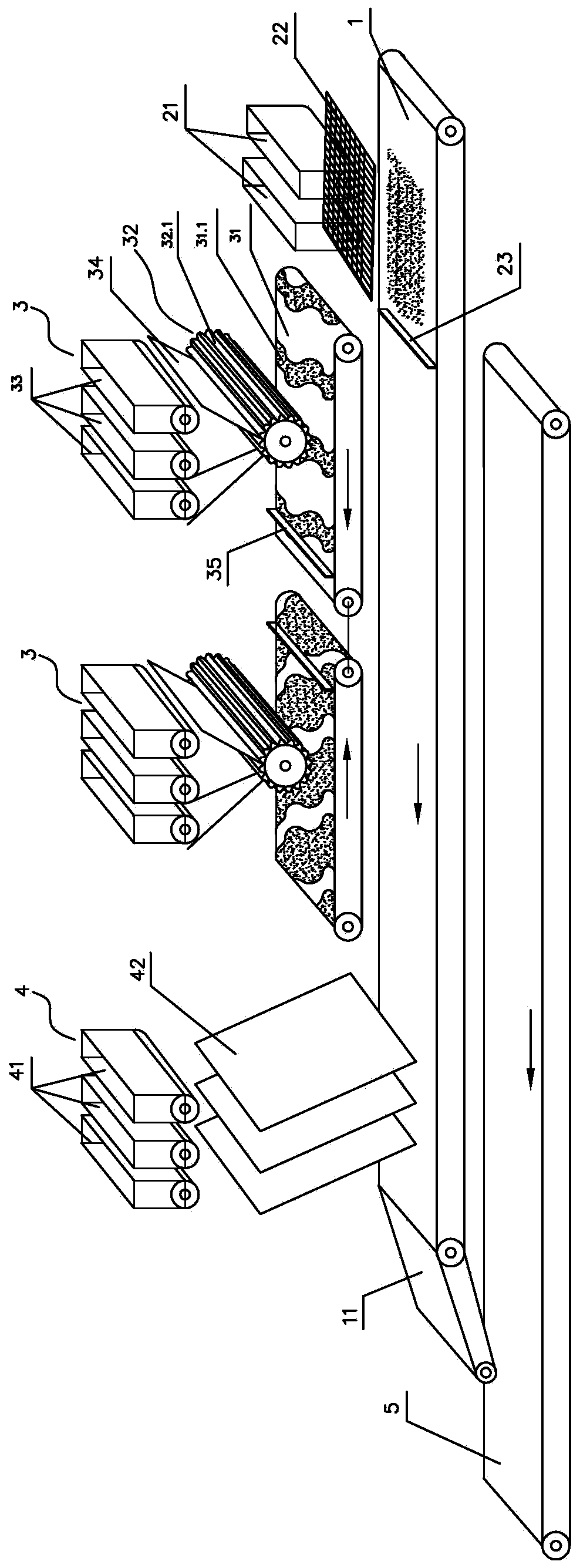

[0017] The Grand Canyon fault is composed of lava flow layers in different periods, and a relatively obvious boundary is formed between the lava flow layers in different periods, and the lava flow layers in the same period are also composed of multi-layer flow layers.

[0018] A method for distributing ceramic tiles imitating the lava flow layer of the Grand Canyon, the steps of which are:

[0019] 1. Use a vibrating screen to sprinkle a thin layer of powder imitating the boundary color of the lava flow layer on the cloth belt at a certain distance, and then scrape it into a line shape. Specifically, high-temperature ultra-white powder and dark transparent powder that imitate the boundary color of lava flow layer can be used to blank according to the set blanking ratio and blanking time, and then spread on the cloth belt after passing through the vibrating screen. Then scrape it into lines with a scraper to imitate the clear dark and transparent border line texture. The interv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com