Preparation method of butadiene

A butadiene and hydrogenation reaction technology, which is applied in hydrocarbon cracking, bulk chemical production, organic chemistry, etc., can solve the problems of low yield of butadiene, achieve high yield, reduce energy consumption, and The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

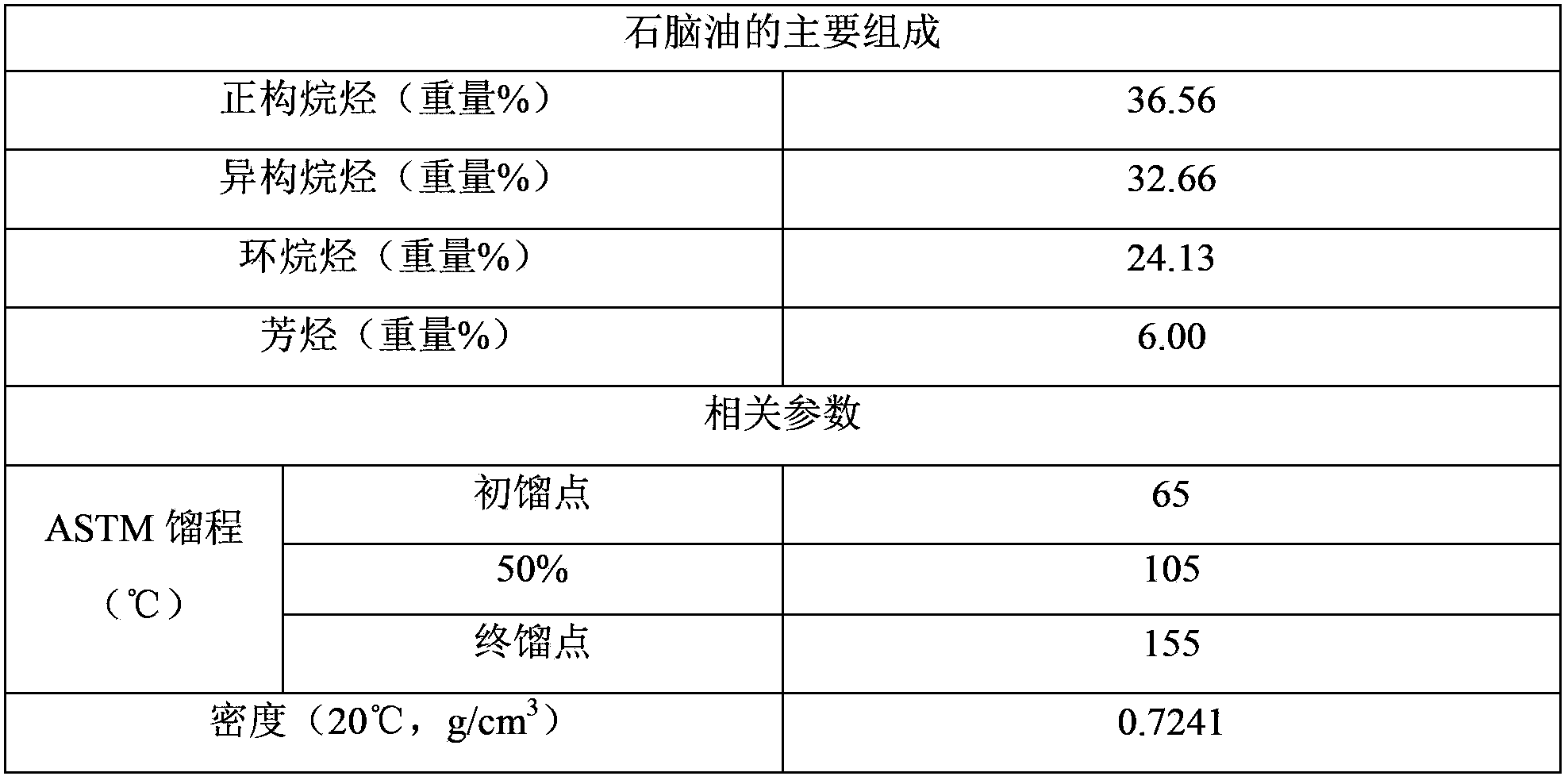

[0015] The preparation method of butadiene according to the present invention comprises: in the presence of a hydrogenation catalyst, carrying out a hydrogenation reaction on a hydrocarbon feedstock containing benzene and / or alkylbenzene, and using the obtained hydrogenation reaction product as at least part of The cracked raw material is subjected to steam cracking reaction.

[0016] In the present invention, since the purpose of the hydrogenation reaction is to convert benzene and / or alkylbenzene in the hydrocarbon feed containing benzene and / or alkylbenzene into cyclohexane and / or alkylcyclohexane Alkanes, so as to achieve the purpose of increasing the yield of butadiene in the steam cracking process, therefore, the hydrocarbon feedstock containing benzene and / or alkylbenzene only needs to contain benzene and / or alkylbenzene components. Preferably, in the hydrocarbon feedstock containing benzene and / or alkylbenzene, the total content of benzene and alkylbenzene is 8-100% by...

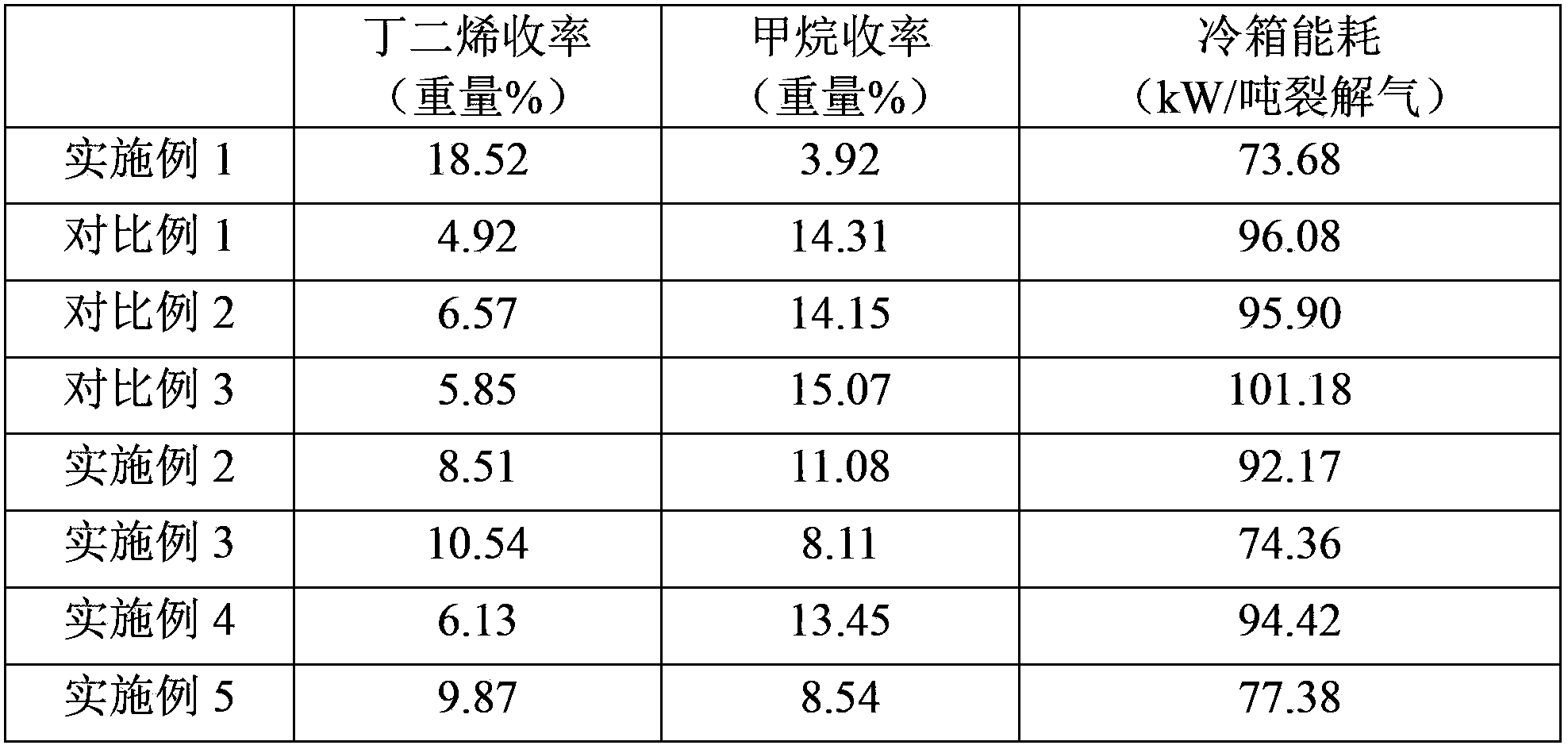

Embodiment 1

[0042] This example is used to illustrate the preparation method of the butadiene of the present invention.

[0043] (1) Hydrogenation

[0044] Benzene is sequentially passed into two reactors for hydrogenation reaction. In the first reactor, the catalyst used is NCG-6 type benzene hydrogenation catalyst (purchased from Catalyst Factory of Nanjing Chemical Industry Co., Ltd., the Ni content is 31.42% by weight, and the carrier is Al 2 o 3 ), the molar ratio of hydrogen to oil is 7, the temperature is 150°C, the absolute pressure is 0.8MPa, and the volumetric space velocity of benzene is 1.1h -1 ; In the second reactor, the catalyst used is NCG-6 type benzene hydrogenation catalyst, the molar ratio of hydrogen to oil is 7, and the absolute pressure is 0.7MPa. Analysis of the liquid-phase hydrogenation reaction product from the second reactor revealed a 99.9% conversion of benzene and a 99.8% selectivity to cyclohexane.

[0045] (2) Steam cracking

[0046] Inject the liquid...

Embodiment 2

[0054] This example is used to illustrate the preparation method of the butadiene of the present invention.

[0055] Carry out hydrogenation and steam cracking according to the method of embodiment 1, difference is, in steam cracking process, the mixture of hydrogenation reaction product and naphtha is injected into CBL-III type cracking furnace with the weight ratio of 1:1 The steam cracking reaction is carried out in the middle, wherein, the feed rate is 24.076 tons / hour, the water-oil weight ratio is 0.5, and the outlet temperature of the furnace tube is 840°C. The cracked gas (that is, the steam cracking reaction product) was analyzed, and the yield of butadiene and methane were calculated, and the results are shown in Table 2 below. Then, the cracked gas was separated according to the method of Example 1, and the energy consumption of the cold box was recorded, the results are shown in Table 2 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com