A kind of method for preparing bensulfuron-methyl

A technology of bensulfuron-methyl and benzsulfonyl isocyanate, which is applied in the field of preparation of bensulfuron-methyl, can solve the problems of many raw materials of bensulfuron-methyl, unsafe operation, high risk of chlorobutane, etc., so as to improve the synthesis yield and The effect of product quality, improvement of conversion rate and reduction of product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

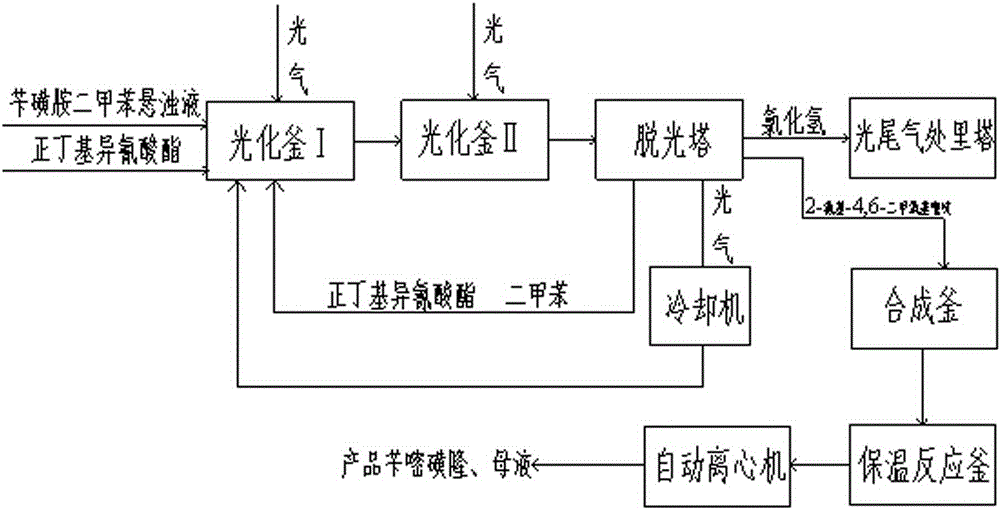

[0018] 33kg / h of phosgene, 127.3kg / h of 30% benzylsulfonamide xylene suspension and catalyst n-butyl isocyanate at a molar ratio of 30:10:1 were continuously added to photochemical reactor I for photochemical reaction. The temperature in Ⅰ is 110℃, the reaction residence time is 2.5h, the synthesis of o-methoxycarboxybenzyl sulfoisocyanate; the reaction containing o-methoxycarboxybenzyl sulfoisocyanate and unreacted phosgene and the catalyst n-butyl isocyanate The mixture was continuously fed into photochemical reactor II, 8.3kg / h of phosgene was added, the molar ratio of phosgene to the benzylsulfonamide xylene suspension was 1.2:4, the temperature in photochemical reactor II was 125℃, and the reaction residence time was 1.5 h, synthesize o-methoxycarboxybenzyl sulfoisocyanate; o-methoxycarboxybenzyl sulfoisocyanate continuously enters the delustering tower, and the extracted n-butyl isocyanate and xylene are returned to the photochemical reactor I for recycling, and the excess...

Embodiment 3

[0020] 33kg / h of phosgene, 127.3kg / h of 30% benzylsulfonamide xylene suspension and catalyst n-butyl isocyanate at a molar ratio of 60:20:3 were continuously added to the photochemical reactor I for photochemical reaction. The temperature in Ⅰ is 115℃, the reaction residence time is 3h, the synthesis of o-methoxycarboxybenzyl sulfoisocyanate; the reaction mixture containing o-methoxycarboxybenzyl sulfoisocyanate and unreacted phosgene and catalyst n-butyl isocyanate Enter the photochemical kettle II continuously, add 8.3kg / h of phosgene, 1.5:4 phosgene and benzylsulfonamide xylene suspension, the temperature in the photochemical kettle II is 127℃, the reaction residence time is 2h, and o-methoxy is synthesized. Benzyl carboxyl benzyl sulfo isocyanate; o-methoxy carboxyl benzyl sulfo isocyanate enters the delustering tower, and the removed n-butyl isocyanate and xylene are returned to the photochemical reactor I for recycling. The excess phosgene is passed through a cooling separ...

Embodiment 4

[0022] 33kg / h of phosgene, 127.3kg / h of 30% benzylsulfonamide xylene suspension and catalyst n-butyl isocyanate at a molar ratio of 20:5:1 were continuously added to photochemical reactor I for photochemical reaction. The temperature in Ⅰ is 120℃, the reaction residence time is 4h, the synthesis of o-methoxycarboxybenzyl sulfoisocyanate; a reaction mixture containing o-methoxycarboxybenzyl sulfoisocyanate and unreacted phosgene and catalyst n-butyl isocyanate Continuously enter the photochemical reactor II, add 8.3kg / h of phosgene, the molar ratio of phosgene to the benzylsulfonamide xylene solution is 2:4, the temperature in the photochemical reactor II is 130℃, the reaction residence time is 3h, and the ortho Methoxy carboxyl benzyl sulfo isocyanate; o-methoxy carboxyl benzyl sulfo isocyanate enters the delustering tower, and the removed n-butyl isocyanate and xylene are returned to the photochemical reactor I for recycling. The excess phosgene is separated by a cooling separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com