Preimpregnation material and laminated board

A prepreg, laminate technology, applied in the direction of layered products, metal layered products, synthetic resin layered products, etc., can solve the problems of cracked copper clad laminate insulation performance, affecting the insulation performance of copper clad laminates, etc., to improve bending resistance and fatigue resistance, improve mechanical properties and interlayer adhesion, and improve the effect of mechanical properties

Active Publication Date: 2014-01-01

GUANGDONG SHENGYI SCI TECH

View PDF2 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, carbon black is a conductive substance, and its addition will significantly affect the insulation performance of copper clad laminates.

[0005] As mentioned above, in the prior art, black particles such as carbon black are added to the thermosetting resin composition to give the copper clad laminate a black function, and the addition of conductive substances in the thermosetting resin composition will crack the insulation performance of the copper clad laminate, so , it is a technical problem to be solved in this field to find a method that can endow the insulation board with a black function without cracking the insulation performance of the copper clad board

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

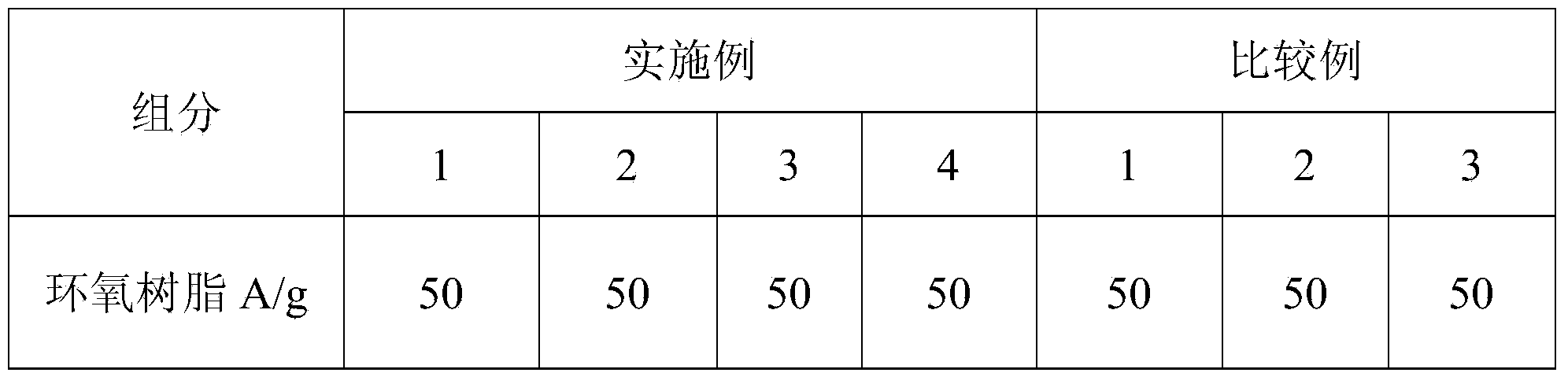

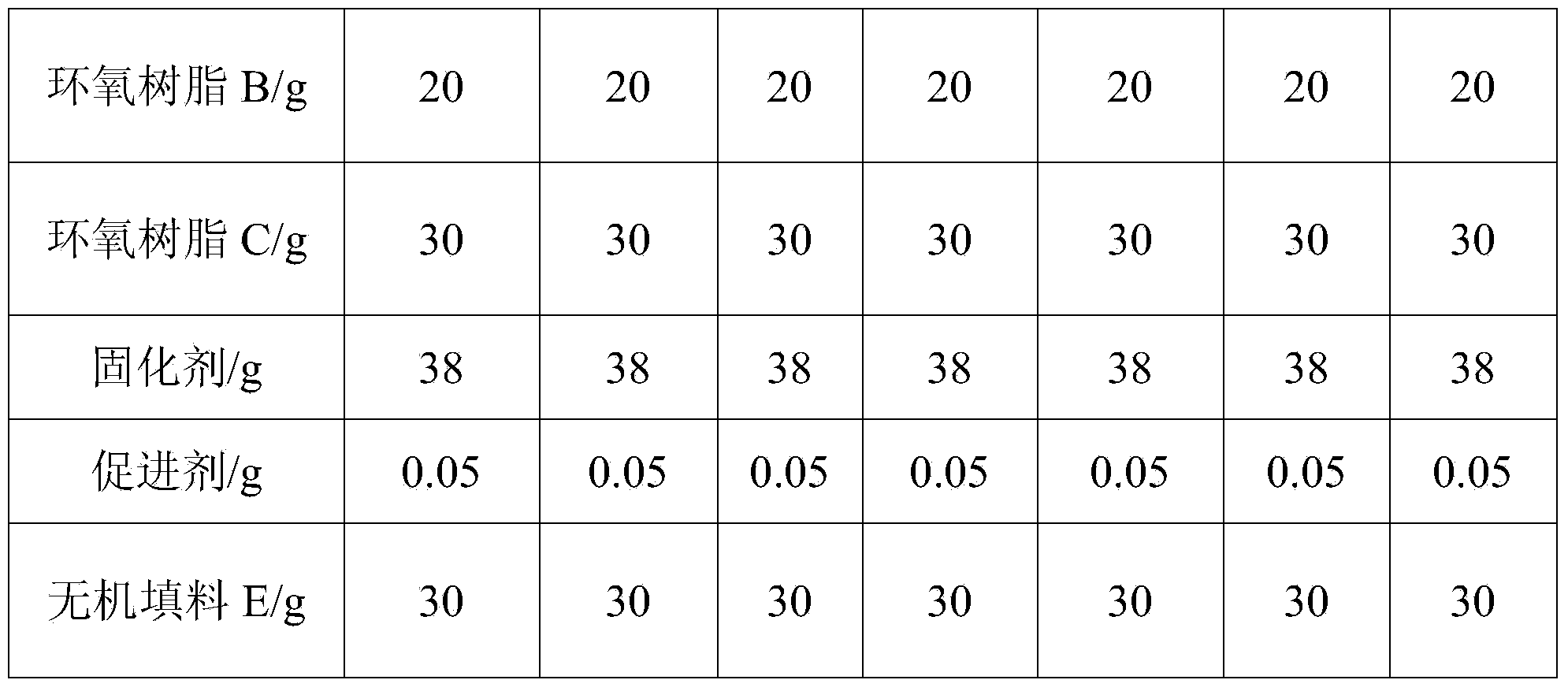

[0056] Example 1 adopts reinforcing material A for dipping, embodiment 2 adopts reinforcing material B for dipping, embodiment 3 adopts reinforcing material C for dipping, embodiment 4 adopts reinforcing material D for dipping, comparative example 1 adopts reinforcing material E for dipping, In comparative example 2, reinforcing material F is used for dipping, and in comparative example 3, reinforcing material G is used for dipping.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

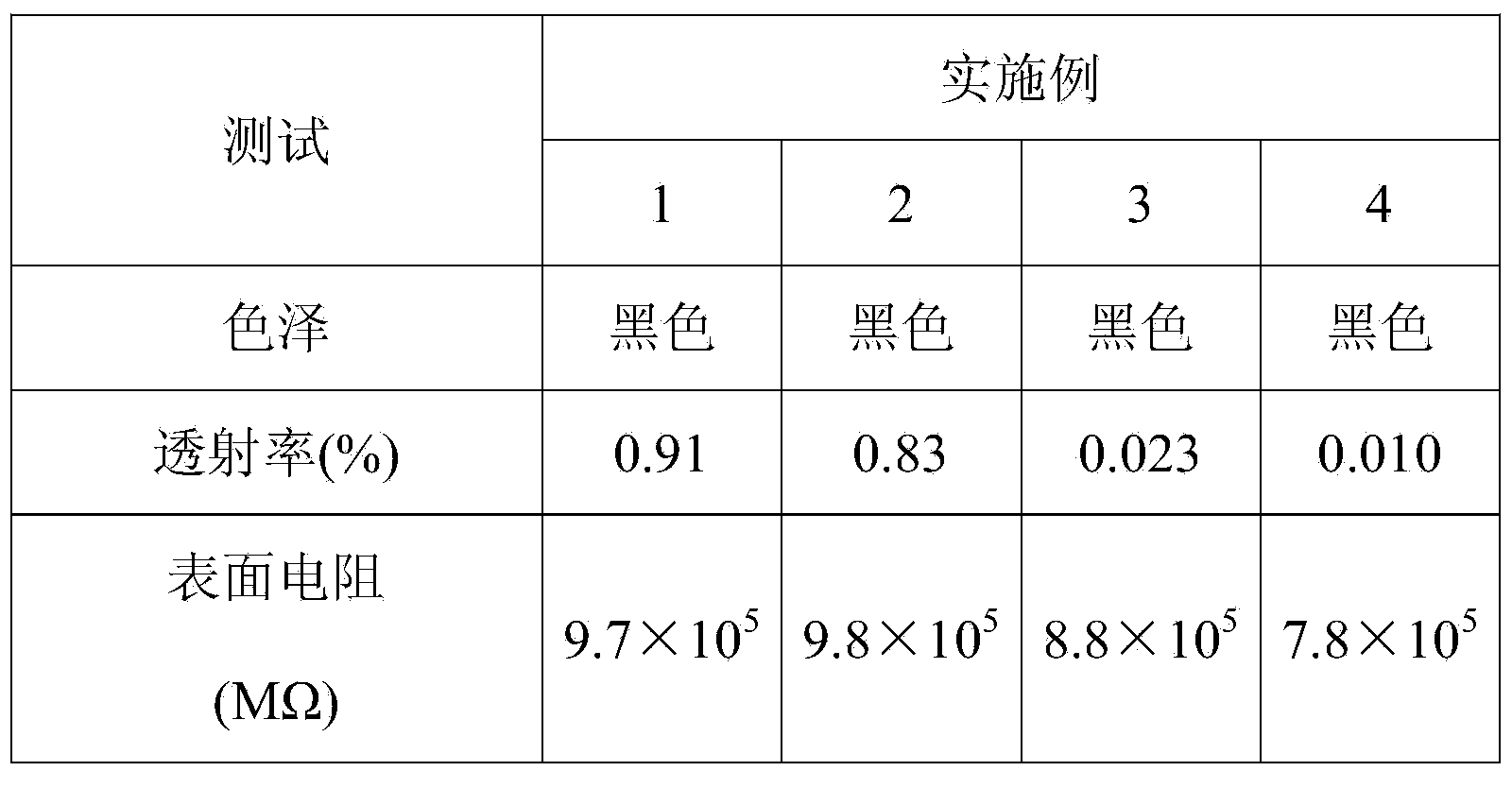

The invention discloses a preimpregnation material which comprises reinforcing materials and heat convertible resin composite materials, wherein the heat convertible resin composite materials are attached to the reinforcing materials after impregnation and drying are carried out, cladding processing is carried out on the reinforcing materials through oxidized graphene or graphene, and the oxidized grapheme or graphene is 0.01-5wt% of the reinforcing materials. According to the preimpregnation material, the reinforcing materials processed by the oxidized grapheme or graphene in the clad mode are added, and the light transmittance of a prepared copper clad substrate is greatly reduced on the premise that the insulativity of the prepared copper clad substrate is not reduced.

Description

technical field [0001] The invention relates to a prepreg and a laminated board. Background technique [0002] Metal foil clad board is a plate-shaped material made by impregnating electronic glass fiber cloth or other reinforcing materials with resin solution, covering one or both sides with metal foil and hot pressing. It is called metal foil clad laminate ( Copper Clad Laminate, CCL), referred to as metal clad. Metal clad board is the substrate material for manufacturing printed circuit board (PCB for short), and PCB is one of the important components of the electronics industry. Almost every kind of electronic equipment, ranging from electronic watches and calculators to computers, communication electronic equipment, and military weapon systems, as long as there are electronic components such as integrated circuits, printed boards are used for the electrical interconnection between them. . The metal clad board is mainly responsible for the three functions of conductio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08K9/10C08L63/00C08J5/24B32B27/04B32B15/092

Inventor 柴颂刚苏晓声

Owner GUANGDONG SHENGYI SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com