Inner liner compound for truck tire

A technology for innerliner adhesives and trucks, which is applied in the field of tire innerliner adhesives. It can solve the problems of high cost, uneven dispersion of carbon black and small materials, and large load capacity, so as to improve service life and safety performance, improve Airtightness and other properties, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] A truck tire inner liner adhesive consists of the following components in parts by weight:

[0081] Natural rubber 10 Bromobutyl rubber 80

[0082] Polyisoprene Rubber LIR 10 Carbon Black N660 53

[0083] Stearic acid 2 Tackifying resin 3

[0084] Leveler 40MSF 3 Aromatic oil 5

[0085] Magnesium Oxide 1.0 Zinc Oxide 4.0

[0086]Antiaging agent 4020 0.5 Antiaging agent RD 0.5

[0087] Antiaging agent 3100 1 Insoluble sulfur 0.8

[0088] Accelerator NS 1.5.

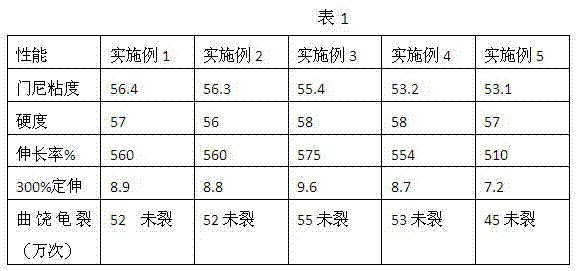

[0089] See Table 1 for performance testing after mixing the finished product.

[0090]

Embodiment 2

[0092] A truck tire inner liner adhesive consists of the following components in parts by weight:

[0093] Natural rubber 10 Bromobutyl rubber 75

[0094] Polyisoprene Rubber LIR 10 Carbon Black N660 53

[0095] Stearic acid 2 Tackifying resin 3

[0096] Leveler 40MSF 3 Aromatic oil 5

[0097] Magnesium Oxide 1.0 Zinc Oxide 4.0

[0098] Antiaging agent 4020 0.5 Antiaging agent RD 0.5

[0099] Antiaging agent 3100 1 Insoluble sulfur 0.8

[0100] Accelerator NS 1.5.

[0101] See Table 1 for performance testing after mixing the finished product.

Embodiment 3

[0103] A truck tire inner liner adhesive consists of the following components in parts by weight:

[0104] Natural rubber 40 Bromobutyl rubber 68

[0105] Polyisoprene Rubber LIR 10 Carbon Black N660 53

[0106] Stearic acid 2 Tackifying resin 3

[0107] Leveler 40MSF 3 Aromatic oil 5

[0108] Magnesium Oxide 1.0 Zinc Oxide 4.0

[0109] Antiaging agent 4020 0.5 Antiaging agent RD 0.5

[0110] Antiaging agent 3100 1 Insoluble sulfur 0.8

[0111] Accelerator NS 1.5.

[0112] See Table 1 for performance testing after mixing the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com