Solid powder burner and use method thereof

A gaseous fuel and powder technology, applied in the direction of granular/powdered fuel gasification, burners, lighting and heating equipment, etc., can solve the unsolved problems of integrated technology, easy burnout of the burner head, and start-up process Complexity and other problems, to achieve the effect of improving the success rate and reliability of driving, convenient production and maintenance, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

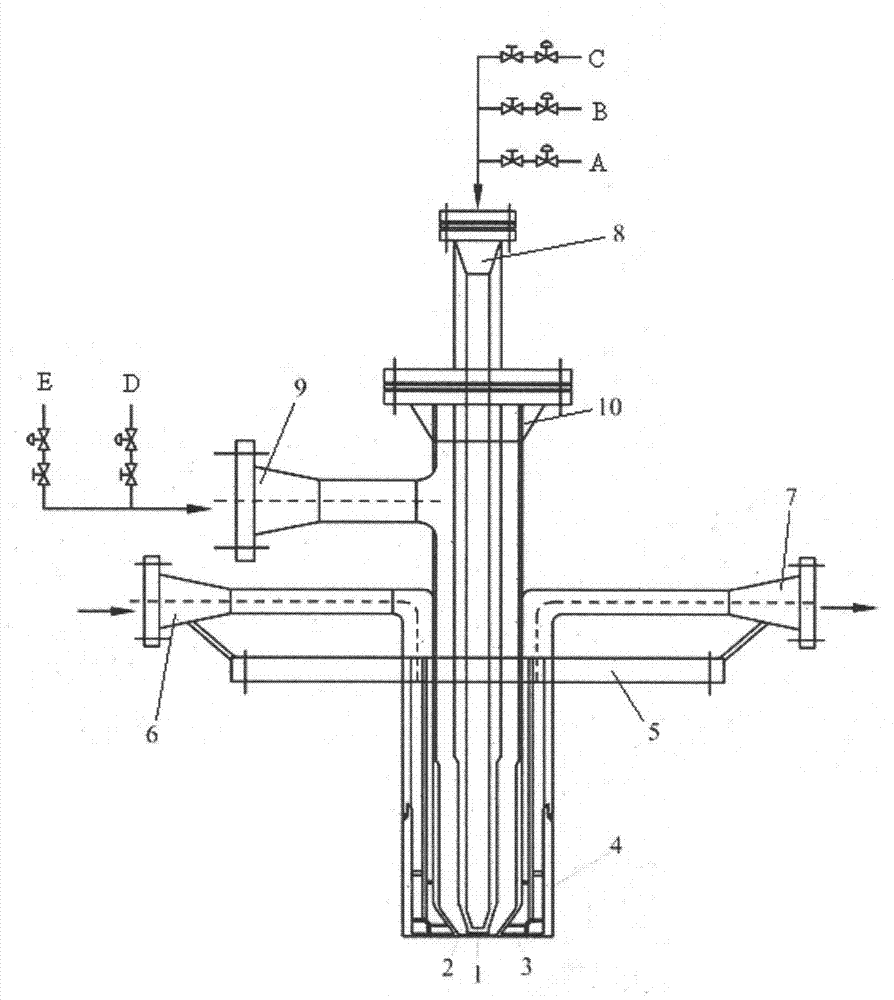

[0037] figure 1 The schematic structural diagram of the solid powder fuel burner provided for Example 1, including a central channel 1 and an annular channel 2 arranged coaxially, one end of the central channel 1 and one end of the annular channel 2 are located on the same plane, forming the head of the burner The other end of the central channel 1 is exposed from the annular channel 2, and the exposed end is provided with a central channel inlet 8; the central channel 1 and the annular channel 2 are connected and fixed through the channel connecting flange 10; the annular channel 2 is provided with a ring The channel inlet 9 and the annular channel 9 communicate with the oxygen-containing gas pipeline D and the annular channel purge gas pipeline E respectively; the cooling channel 3 is arranged outside the head of the annular channel 2, and the cooling channel 3 is arranged coaxially with the central channel 1 and the annular channel 2 The two sides of the cooling channel 3 a...

Embodiment 2

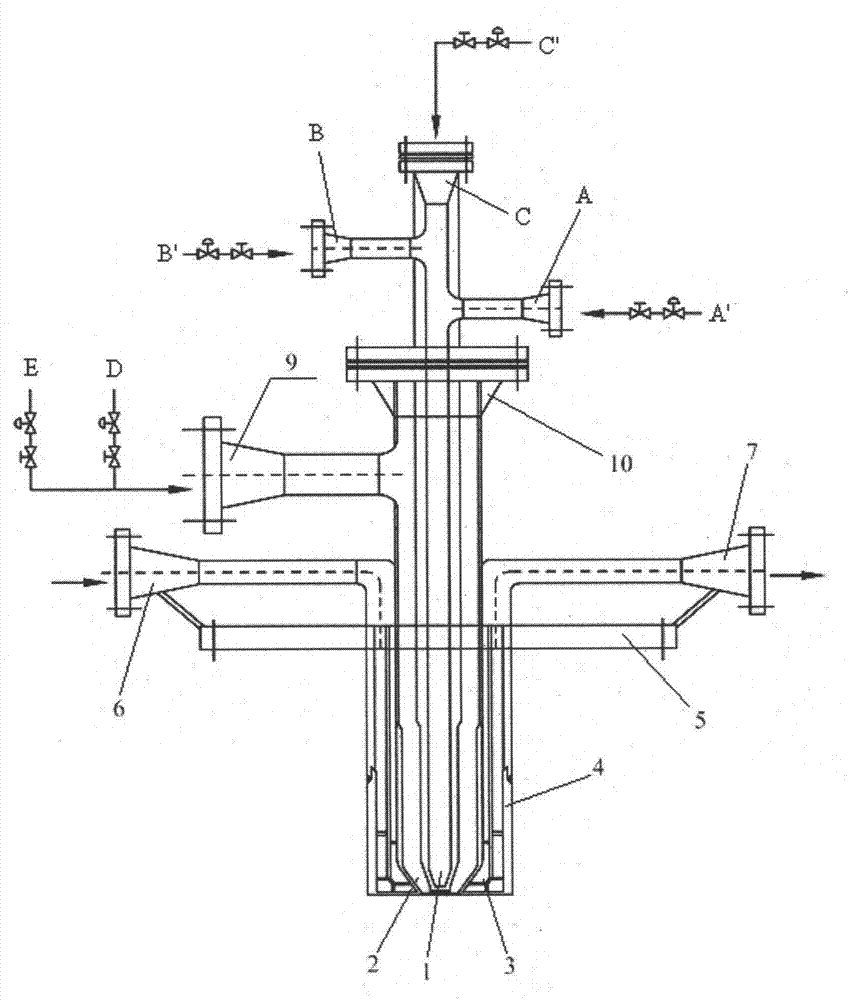

[0052] Such as figure 2 As shown, the schematic diagram of the solid powder fuel burner provided in Example 2 includes a central channel 1 and an annular channel 2 coaxially arranged, and one end of the central channel 1 and one end of the annular channel 2 are located on the same plane, forming a burner The head of the mouth; the other end of the central channel 1 is exposed from the annular channel 2, and the exposed end is provided with three central channel inlets 8; the central channel 1 and the annular channel 2 are connected and fixed through the channel connecting flange 10; An annular channel inlet 9 is provided, and the annular channel 9 communicates with the oxygen-containing gas pipeline D and the annular channel purge gas pipeline E respectively; a cooling channel 3 is provided outside the head of the annular channel 2, and the cooling channel 3 is connected with the central channel 1 and the annular channel 2 Coaxial arrangement; the two sides of the cooling cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com