Fully automatic multi-station rotary ferrule parts molding quenching press

A mold press quenching, multi-station technology, applied in the direction of quenching device, manufacturing tool, furnace type, etc., can solve the problem that the surface hardness and metallographic structure of the inner and outer rings of the bearing do not meet the requirements, the quenching process is uncontrollable, and the machining surplus is increased. To achieve rapid and uniform cooling, ensure hardness and structure, and prevent deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

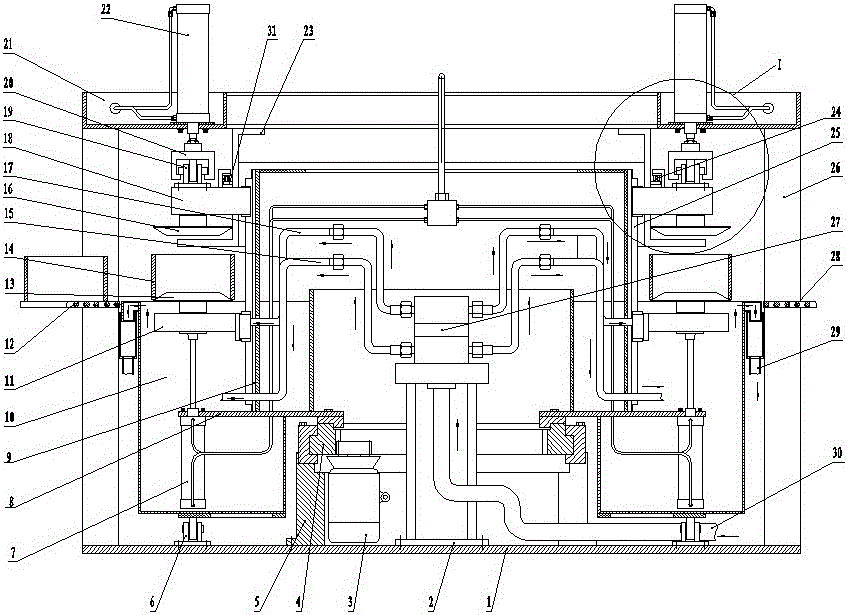

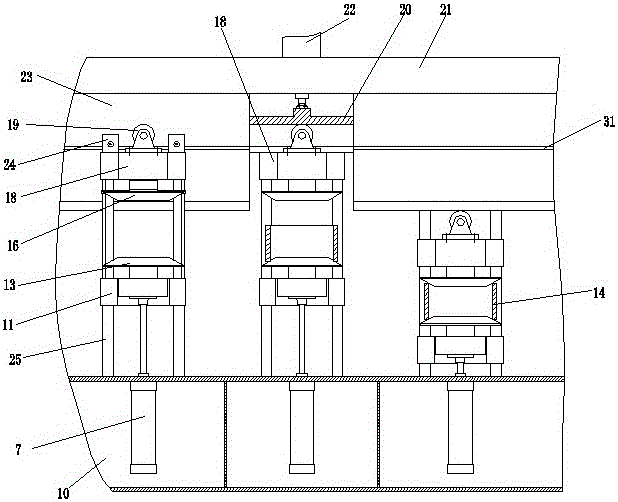

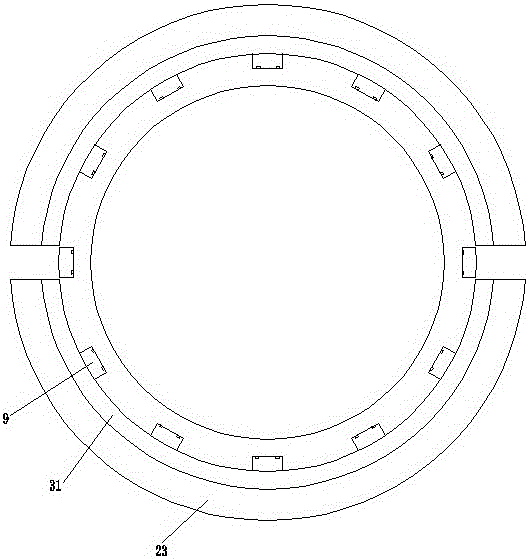

[0026] Among 1, 2, 3, and 4 in the figure, 1-base, 2-rotary valve bracket, 3-motor, 4-rotary support ring, 5-rotary support seat, 6-support wheel, 7-lower mold cylinder, 8- Circular rotary table, 9-bed, 10-circular quenching oil tank, 11-lower slider, 12-feeding roller table, 13-lower mold, 14-quenched ferrule parts, 15- Oil outlet pipeline Ⅰ, 16-upper mold, 17-oil outlet pipeline II, 18-upper slider, 19-guiding wheel, 20-converting pressure head, 21-circular main frame, 22-upper mold cylinder, 23- "L" shaped ring support frame, 24—suspension wheel, 25—vertical guide rail, 26—support column, 27—rotary distribution valve, 28—discharge roller table, 29—oil return pipe, 30—cooling oil inlet pipeline, 31—annular guide rail.

[0027] Such as figure 1 , 2 As shown in , 3 and 4, an annular track is installed on the base 1, and support wheels 6 are installed on the bottom of the circular quenching oil tank 10 with a "U" shape in cross section, and are evenly distributed and fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com