Guide-tube-cooled oil-immersed transformer

A heat dissipation oil and transformer technology, applied in the field of transformers, can solve problems such as inability to work continuously for a long time, troublesome replacement and maintenance of fans, power consumption of cooling fans, etc., and achieve the effects of simple structure, saving raw materials, and fast heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

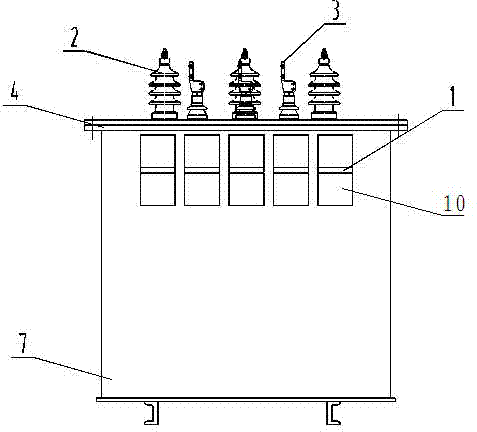

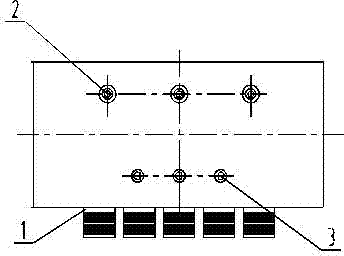

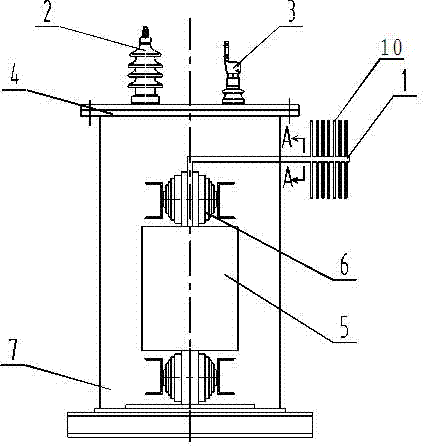

[0018] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a box body 4 with a winding 5 and an iron core 6 assembled therein. A high-voltage connection terminal 2 and a low-voltage connection terminal 3 are installed above the box body 4. A heat dissipation device 1 is installed on the box body 4. The heat dissipation device 1 includes One end is inserted into the conduit 8 inside the iron core 6, the other end of the conduit 8 extends out of the box body 4 and several cooling fins 10 are arranged at the end, the conduit 8 and the cooling fins 10 are filled with cooling liquid 9; the box body 4 is filled with Transformer oil7.

[0019] The transformer oil 7 is used as a dielectric and a heat conducting medium, and transfers heat to the surface of the box body 4 to dissipate heat. The cooling device 1 includes a conduit 8, a cooling liquid 9 and several cooling fins 10. Fast, large heat conduction capacity, can instantly ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com