A kind of patterned substrate and LED chip for LED formal installation structure

A patterned substrate and LED chip technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing the life of LED chips with internal quantum efficiency, high manufacturing costs of nanometer-level patterns, and limiting popularization and application. Effects of quantum efficiency, improvement of epitaxy quality, and excellent light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

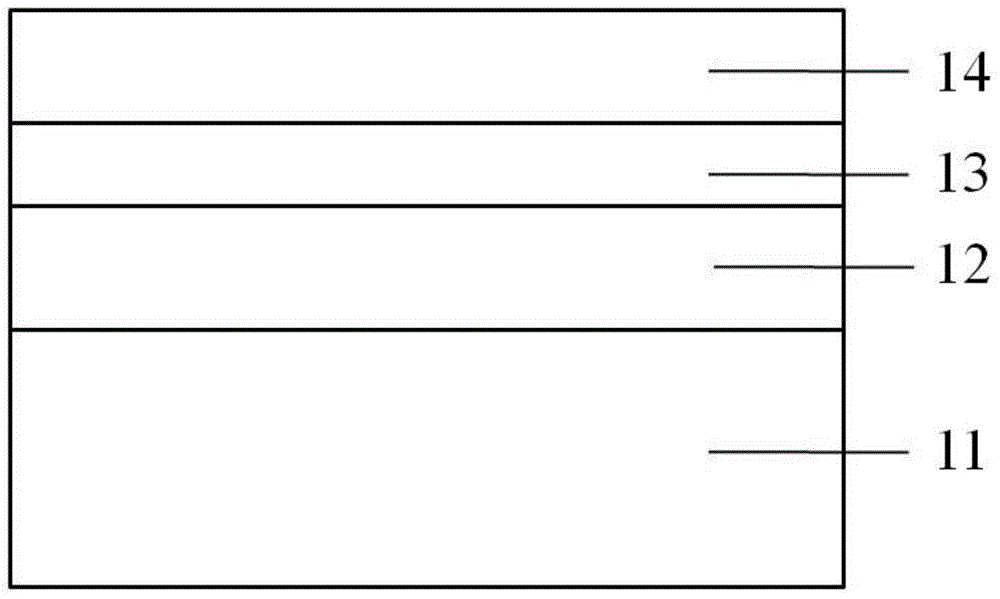

[0026] figure 1 It is a schematic diagram of the LED chip of this embodiment, which consists of a sapphire patterned substrate 11 , an N-type GaN layer 12 , an MQW quantum well layer 13 , and a P-type GaN layer 14 arranged in sequence.

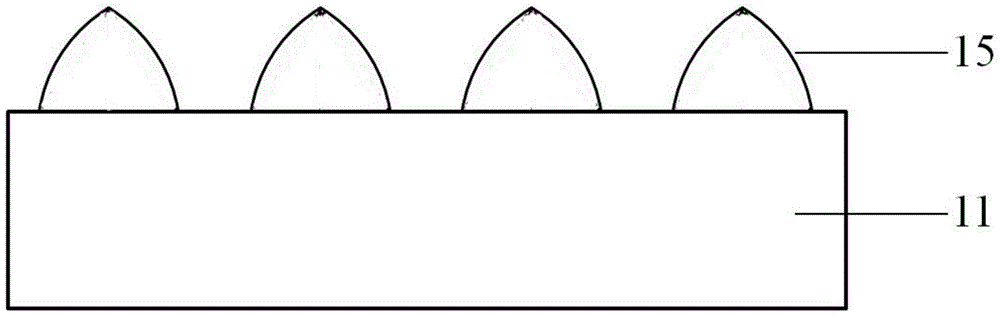

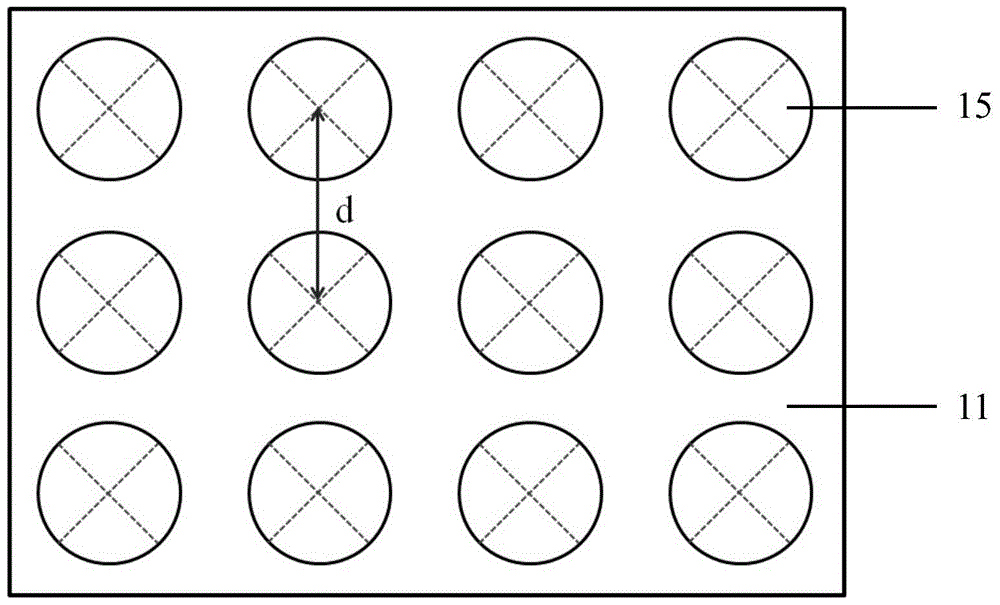

[0027] Such as figure 2 As shown, this embodiment is used for the sapphire patterned substrate 11 of the LED positive mounting structure, and the pattern of the substrate is composed of a plurality of dome-shaped patterns 15 of the same shape arranged on the surface of the substrate.

[0028] Such as Figure 3-4 As shown, the dome-shaped pattern is an axisymmetric cone, the bottom surface of the cone is a circle with a radius R of 1.2 μm, and the height h of the cone is 1.5 μm. Such as Figure 4 As shown, the cross-section of the vertebral body along the axis of symmetry is a triangular-like shape composed of two symmetrical arcs and a straight line. Point O in the figure is the center of the circle corresponding to the arc AB, and the cen...

Embodiment 2

[0032] In this embodiment, except the following features, all the other features are the same as in Embodiment 1:

[0033] The dome-shaped pattern is an axisymmetric cone, the base of the cone is a circle with a radius of 0.8 μm, and the height of the cone is 1.3 μm. The cross-section of the vertebral body along the axis of symmetry is a triangular-like shape composed of two symmetrical arcs and a straight line; the central angle corresponding to the arcs is 5°; the distance between adjacent vertebral bodies is 2.0 μm.

[0034] The test result of this embodiment is close to embodiment 1.

Embodiment 3

[0036] In this embodiment, except the following features, all the other features are the same as in Embodiment 1:

[0037] The dome-shaped pattern is an axisymmetric cone, the base of the cone is a circle with a radius of 1.2 μm, and the height of the cone is 1.6 μm. The cross-section of the vertebral bodies along the axis of symmetry is a triangular-like shape composed of two symmetrical arcs and a straight line; the central angle corresponding to the arcs is 15°; the distance between adjacent vertebral bodies is 4.0 μm.

[0038] The test result of this embodiment is close to embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com