Optical fiber and fiber laser comprising optical fiber

A fiber laser and fiber technology, which is applied in the directions of multi-layer core/clad fibers, clad fibers, optical waveguides, etc., can solve problems such as unfavorable construction of high-power fiber lasers, reduction of fiber damage threshold, and reduction of laser stability. , to improve the anti-irradiation and anti-photo-darkening performance, avoid insertion loss and thermal load, and improve the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

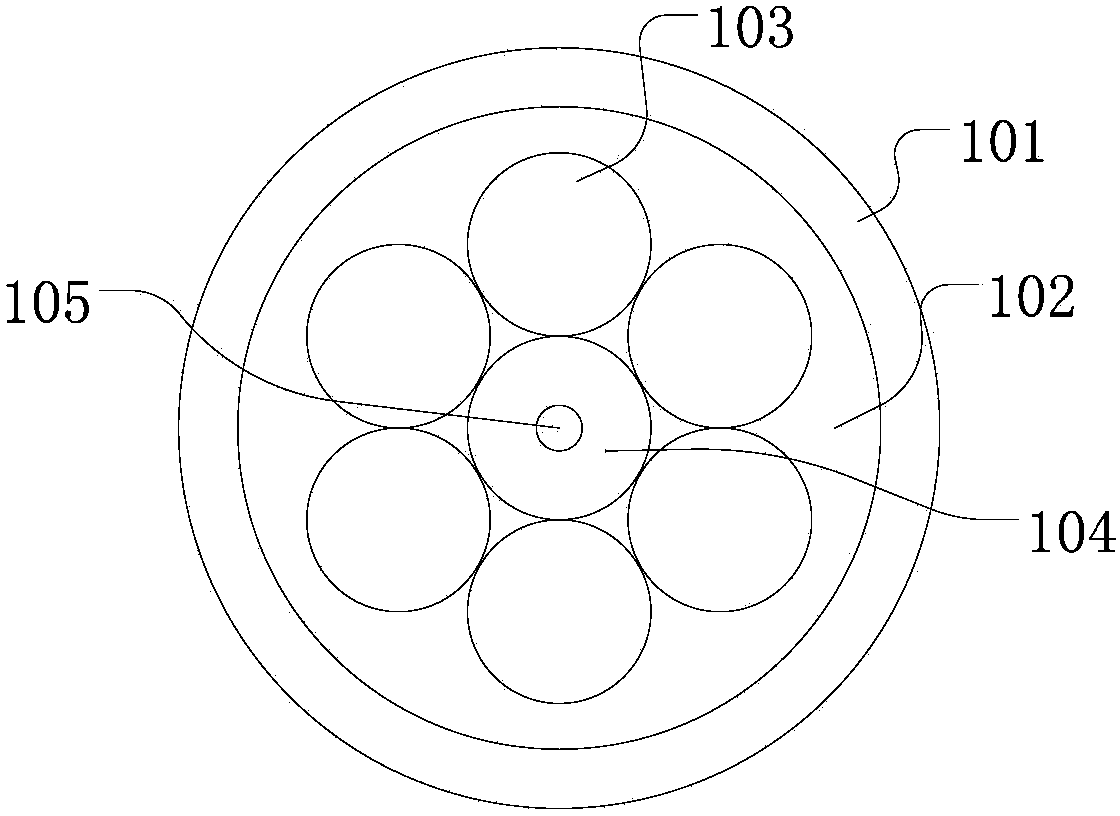

[0028] A preferred example of the present invention one, the structure is as Figure 5 As shown, first take a 20m structure such as figure 2 The new structure fiber shown, in which the gain medium of the active core is Yb 3+ , the pump core 103 has a diameter of 400 μm, the active core 104 has a diameter of 400 μm, and the doped region 105 has a diameter of 20 μm. The 20 cm coating layer at both ends is stripped off, and the two cores 103 and 104 in the fiber will naturally separate , and then write a 1080nm high reflection grating 304 at one end of the active fiber core 104, and write a 1080nm low reflection grating 303 at the other end, wherein the high reflection grating 304 has a reflectivity of 98% to 1080 nm, and the low reflection grating 303 has a 1080nm reflectivity 20%, and then the two ends of the pump core are fused with the 975nm semiconductor laser 302. When the pump power is 40W, the 1080nm laser output from the output port 301 is 28.8W.

example 2

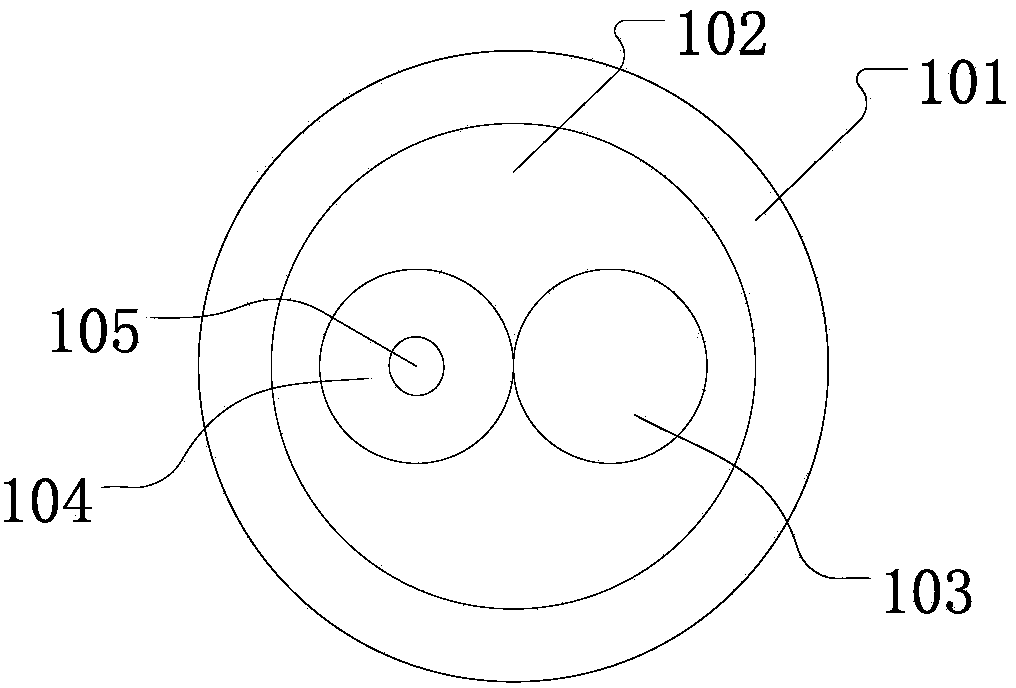

[0030] The second preferred example of the present invention has a structure such as Image 6 As shown, first take a 20m structure such as image 3 The novel structure optical fiber shown (wherein, n=2), wherein the gain medium of the active core is Yb 3+ , the pump core 103 has a diameter of 200 μm, the active core 104 has a diameter of 600 μm, and the doped region 105 has a diameter of 60 μm. The 20 cm coating layer at both ends is stripped off, and the three cores in the optical fiber will naturally separate. Then write the high reflective grating 304 of 1080nm at one end of the active fiber core 104, and write the low reflective grating 303 of 1018nm at the other end, wherein the high reflective grating 304 is 98% to 1080 reflectivity, and the low reflective grating 303 is 1080nm. 20%, and then the pump core is fused with a 915nm semiconductor laser 302. When the pumping power is 80W, the 1080nm laser output from the output port 301 is 60.8W.

example 3

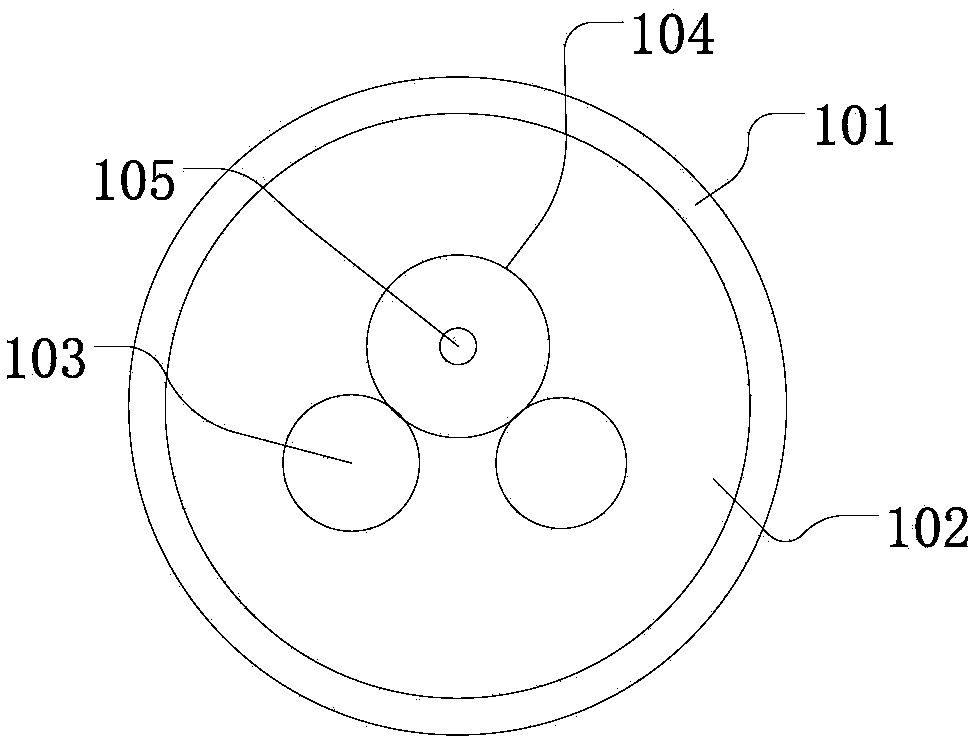

[0032] The third preferred embodiment of the present invention has a structure such as Figure 5 As shown, first take the 7m structure such as Figure 4 The new structured fiber shown, where the gain medium of the active core is Tm 3+ , the pump core 103 has a diameter of 130 μm, the active core 104 has a diameter of 130 μm, and the doped region 105 has a diameter of 10 μm. The 20 cm coating layer at both ends is stripped off, and the two cores 103 and 104 in the fiber will naturally separate , and then write a high reflection grating 304 of 1950nm at one end of the active fiber core 104, and write a low reflection grating 303 of 1950nm at the other end, wherein the high reflection grating 304 has a reflectivity of 98% to 1950, and the low reflection grating 303 has a reflectivity of 1950nm 20%, and then the pump core is fused with a 793nm semiconductor laser 302. When the pumping power is 40W, the 1950nm laser output from the output port 301 is 27.4W.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com