Method for modifying water treatment inorganic catalytic membrane

A catalytic membrane and water treatment technology, applied in chemical instruments and methods, osmotic/dialysis water/sewage treatment, membrane technology, etc., can solve the problems of weak anti-fouling ability and no catalytic performance of inorganic membranes, and achieve good industrial application prospects , Improved anti-pollution ability, easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

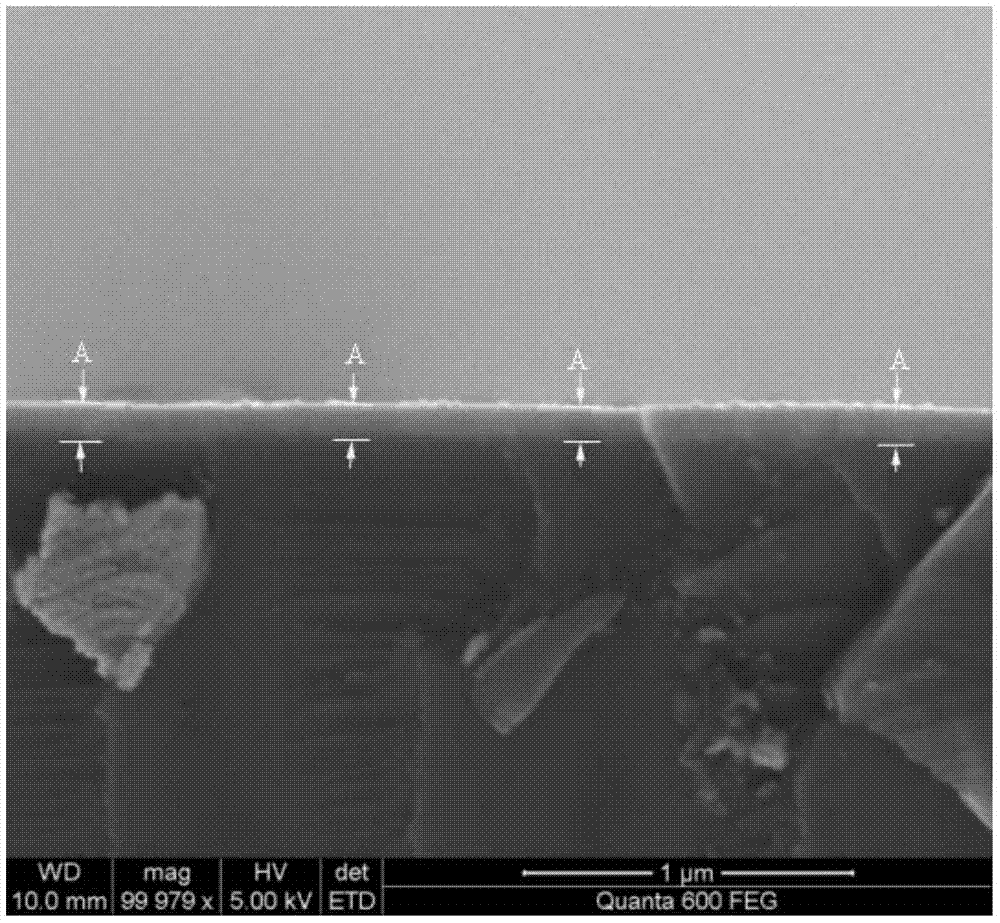

Image

Examples

specific Embodiment approach 1

[0015] Embodiment 1: In this embodiment, a method for modifying inorganic catalytic membranes for water treatment is realized according to the following steps: immerse the inorganic membrane in pure water, take it out after 24-48 hours, and then directly immerse it in Immersing in the solution for 0.5h to 8h to obtain a modified inorganic membrane; wherein the solution is an oxidant solution or a reducing agent solution, and the mass concentration of the solution is 0.1mg / L to 500mg / L;

[0016] Or immerse the inorganic membrane in pure water, take it out after 24 to 48 hours, and then immerse it in the oxidant solution and the reducing agent solution respectively, the immersion time is 2h to 5h, take it out, and obtain the modified inorganic membrane; The mass concentration of the reducing agent solution is 0.1 mg / L to 500 mg / L, and the mass concentration of the reducing agent solution is 0.1 mg / L to 500 mg / L.

specific Embodiment approach 2

[0017] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the inorganic membrane is a flat membrane or a tubular membrane. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is: the said immersion into the oxidizing agent solution and the reducing agent solution respectively refers to: first immerse in the reducing agent solution, soak for 2 hours, take it out and then Immerse in the oxidizing agent solution, immerse for 2 hours, take out, and obtain the modified inorganic membrane. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com