Rapid setting early-strength anti-aqueous dispersion grouting material and preparation method thereof

A technology for water-resistant dispersion and grouting materials, applied in the field of quick-setting early-strength water-resistant dispersion grouting materials and its preparation, can solve problems such as water inrush and mud gushing, and achieve strength without shrinkage, fast strength, and strength growth quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

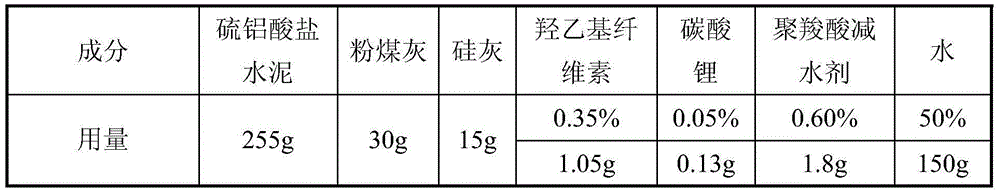

Embodiment 1

[0026]

[0027] The preparation method comprises the following steps:

[0028] 1) Weigh sulfoaluminate cement, fly ash and silica fume according to the above mass, put them in the mixer, mix slowly at room temperature for 1min, weigh hydroxyethyl cellulose and lithium carbonate, and slowly add them into the mixer , stir slowly at room temperature for 1 min;

[0029] 2) Add the weighed polycarboxylate water reducer into the weighed water, and mix evenly to obtain an aqueous solution of the water reducer;

[0030] 3) When in use, add component C into the mixer and stir slowly for 2 minutes to obtain the quick-setting early-strength water-resistant dispersion grouting material.

[0031] Fluidity test method: Use a cross-sectional cone with an upper circle of 70mm, a lower circle of 100mm, and a height of 60mm to test the slurry fluidity. Place the cone on a wet smooth glass plate, fill the cone with the freshly mixed slurry, lift the cone vertically quickly, and measure the ...

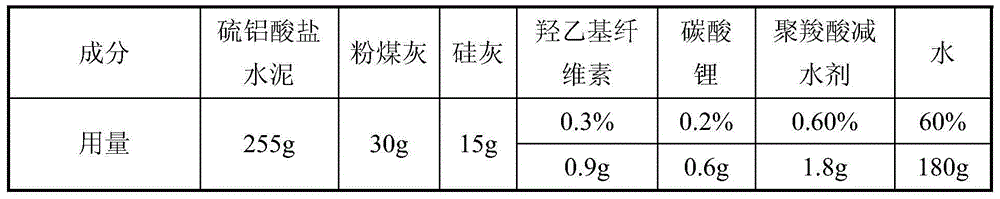

Embodiment 2

[0037]

[0038] The preparation method is the same as in Example 1.

[0039] In this embodiment, the grouting material is initially set at room temperature for 8 minutes and finally set for 14 minutes. Its fluidity is 23 cm, and its early strength increases rapidly. The strength at 7 days can reach more than 90% of the strength at 28 days, and it has excellent underwater resistance. Dispersion properties, rapid strength growth, and high final strength.

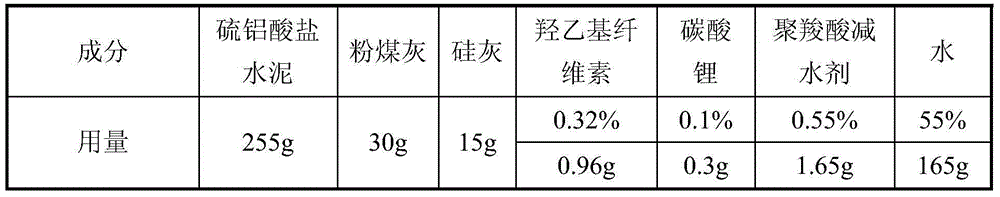

Embodiment 3

[0041]

[0042] In this example, the grouting material is initially set at room temperature for 10.5 minutes, and finally set for 16.5 minutes. Its fluidity is 22 cm, and its early strength increases rapidly. The strength at 7 days can reach more than 90% of the strength at 28 days, and it has excellent underwater resistance. Dispersion properties, rapid strength growth, and high final strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com