Cross-linking agent applicable to highly-mineralized water fracturing fluid

A technology with high salinity and cross-linking agent, applied in the fields of organic chemistry, drilling compositions, chemical instruments and methods, etc., can solve the problems of poor shear resistance, consumption of alkali, damage, etc. Injury, cost reduction, freshwater saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

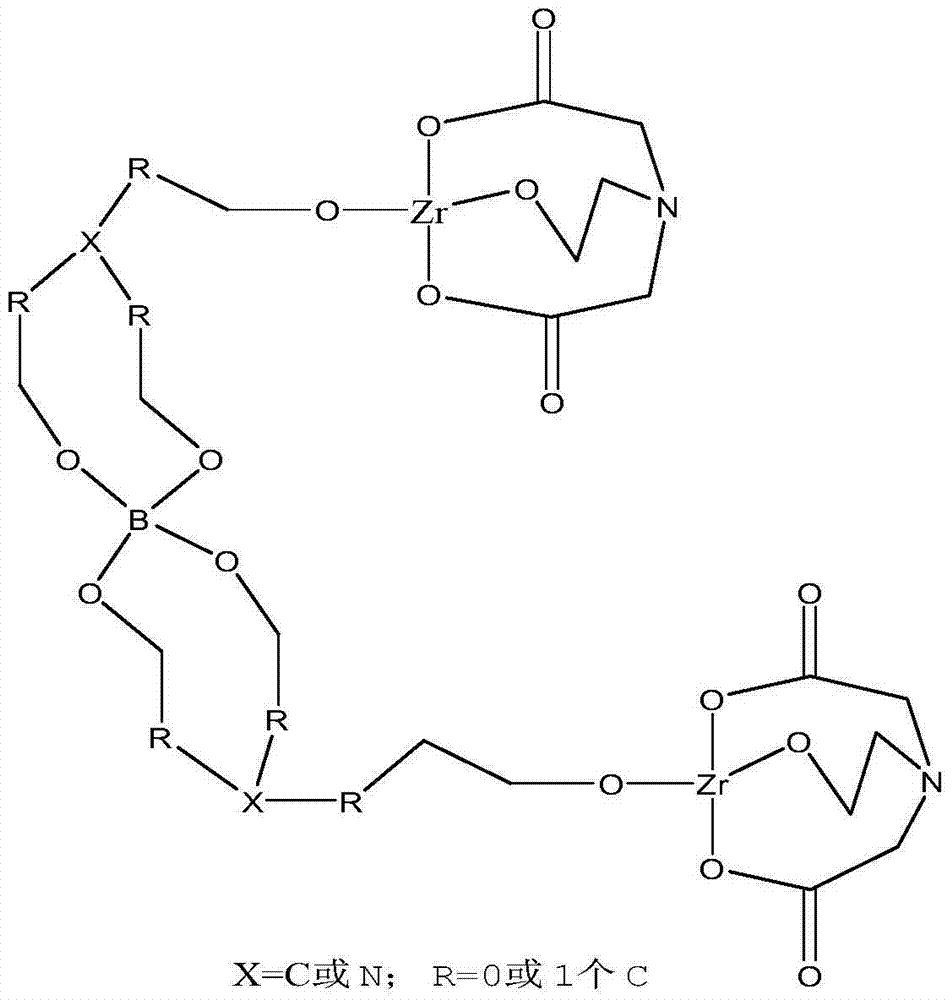

Method used

Image

Examples

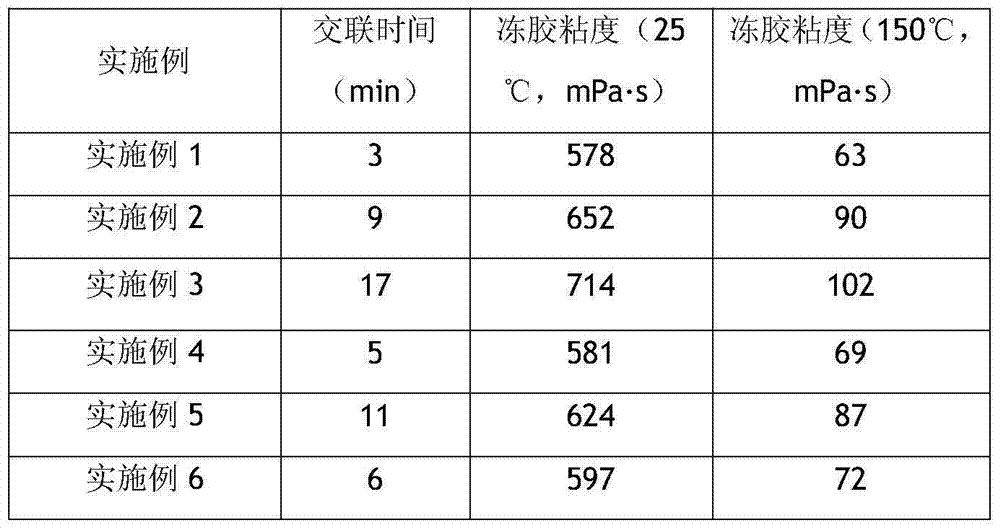

Embodiment 1

[0013] Add 5kg of clear water to the enamel liner reactor, slowly add 9kg of zirconium acetate, and stir for 30 minutes; quickly add 9kg of N,N-bis(2-hydroxyethyl)glycine, slowly raise the temperature to 60°C, and stir for 1h; then add 3kg of boric acid, add 8kg of triethanolamine dropwise during stirring; stir at 80°C for 5h, add 66kg of water to obtain a slightly yellow transparent crosslinking agent.

Embodiment 2

[0015] Add 5kg of clear water to the enamel liner reactor, slowly add 17kg of zirconium oxychloride, and stir for 30 minutes; quickly add 17kg of N,N-bis(2-hydroxyethyl)glycine, slowly raise the temperature to 60°C, and stir for 1h; Add 40kg borax again, add dropwise 9kg glycerol in the stirring process. Stir at 80°C for 5 hours, and add 12kg of water to obtain a light yellow transparent crosslinking agent.

Embodiment 3

[0017] Add 5kg of clear water to the enamel liner reactor, slowly add 17kg of zirconium oxychloride, and stir for 30 minutes; quickly add 17kg of N,N-bis(2-hydroxyethyl)glycine, slowly raise the temperature to 60°C, and stir for 1h; Then add 40kg of borax, add 2kg of glycerol, 4kg of triethanolamine and 3kg of mannitol dropwise during stirring; stir at 80°C for 5 hours, add 12kg of water to obtain a light yellow transparent crosslinking agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com