Device and method for inhibiting growth of microorganisms in xylose liquid

A technology of microbes and xylose, applied in sugar production, sugar production, food science, etc., can solve problems such as mixing xylose crystal products, affecting product purity, and production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

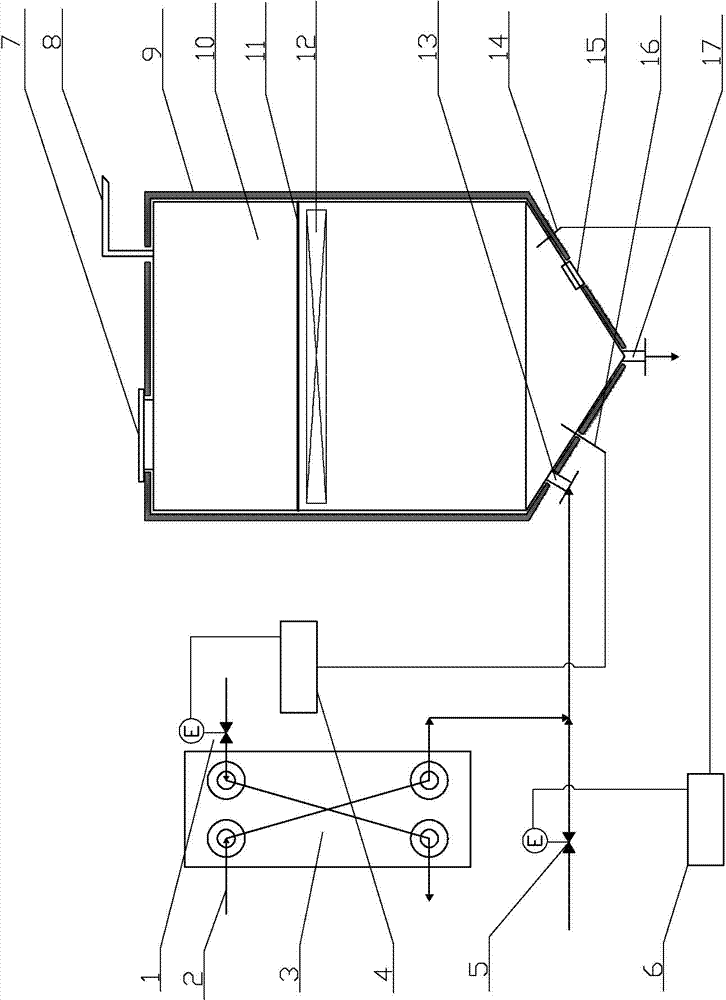

[0020] As shown in the figure, the two openings at the upper end of the plate heat exchanger 2 are the feed liquid inlet 2 and the heat source inlet respectively, and the two openings at the lower end are the heat source outlet and the feed liquid outlet respectively; the heat source flow control solenoid valve 1 is set at the heat source inlet; the temporary storage tank Manhole 7 and ventilation hole 8 are arranged at the upper end of 10, and the ultrafiltration membrane is built in the ventilation hole 8, and the feeding port 13, the discharging port 17, the eyepiece 15, the pH meter 14, the thermocouple 16, and the temporary storage tank 10 are arranged at the lower end of the temporary storage tank 10. Insulation material 9 is arranged on the outer periphery, and a floating device is arranged inside the temporary storage tank 10. The floating device is composed of a supporting part and a sealing part. The supporting part is a conical plate, which is spliced by 12 fan-shap...

Embodiment 2

[0023] The heat exchanger is a shell-and-tube heat exchanger, and the heat source used is fresh steam. After the feed liquid passes through the heat exchanger, the temperature rises to 50 °C. The addition of acetic acid is controlled by the pH control PID module 6, so that the pH of the material liquid is between 4-5, and the pH of the material at the outlet of the temporary storage tank is 4.25-4.70. The light transmittance at 420 nm is above 99%. Observed through the eyepiece, no microbial growth.

Embodiment 3

[0025] The pH of the feed solution is 4.5-5, the temperature is 20°C, and the light transmittance at 420 nm detected by a spectrophotometer is above 99.5%. The heat source inlet temperature of the plate heat exchanger is 85 °C, and the temperature of the feed liquid rises to 55 °C after passing through the heat exchanger. The pH of the material at the outlet of the temporary storage tank is 4.20-4.70. The light transmittance at 420 nm is above 98.5%. Observed through the eyepiece, no microbial growth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com