Hydraulic control circuit with locking function

A liquid level control and liquid level technology, applied in steam boiler components, steam boiler accessories, steam boilers, etc., can solve the problems of easy polarization corrosion of electrodes, electrification of the device under test, and reduced safety factor, so as to avoid Output jitter, prolong service life, avoid the effect of switching electrical appliances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

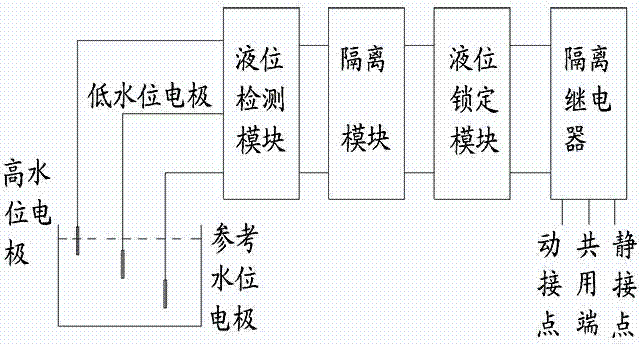

[0010] Such as figure 1 As shown, the liquid level control circuit with lock is composed of a liquid level detection module, an isolation module and a liquid level state locking module. The liquid level detection module judges the level of the liquid level by comparing the liquid level relationship between the reference liquid level electrode and the high and low liquid level electrodes; the liquid level electrode bears extremely small AC current, and the electrode is not easily polarized; Ordinary metal rods are enough. In order not to affect the quality of the liquid itself, stainless steel pipes should be used.

[0011] The isolation module uses isolation bridge technology to safely transmit the liquid level detection signal to the internal logic locking circuit. Its advantage is that when the external liquid level detection module breaks down or has high voltage intrusion, it does not affect the internal logic circuit, and the voltage isolation is as high as 3500Vrms, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com