Tritium breeding blanket system based on lithium deuteroxide heavy water solution

A technology for lithium deuterium oxide and tritium multiplication, applied in nuclear reactors, nuclear power generation, climate sustainability, etc., to achieve the effects of easy online refueling, easy processing, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

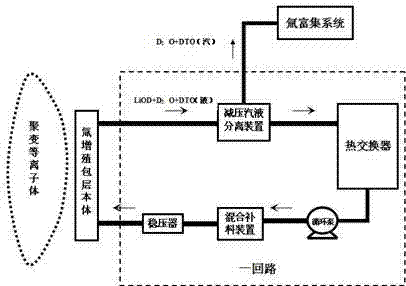

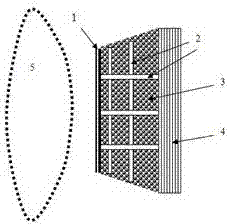

[0024] The tritium breeding cladding system for the fusion reactor engineering technology experiment platform based on the heavy aqueous solution of lithium deuterium oxide is as follows: figure 1 As shown, the system consists of three parts: the tritium breeding cladding body, the primary circuit system, and the tritium enrichment system. The tritium breeding cladding body and the primary circuit system are connected through the fluid inlet and the fluid outlet. The vapor outlet of the vacuum vapor-liquid separation device is connected to the tritium enrichment system.

[0025] The system uses heavy water saturated solution of lithium deuterium oxide as the tritium breeding agent and coolant, wherein the molar concentration of lithium deuterium oxide is between 5mol / l, the inlet temperature of the tritium breeding cladding body is 120°C, the outlet temperature is 150°C and the working pressure is 1MPa . This parameter is based on the consideration that the fusion reactor eng...

Embodiment 2

[0030] Tritium breeding cladding system for fusion demonstration reactor based on heavy deuterium oxide lithium solution. The system consists of three parts: tritium breeding cladding body, primary loop system and tritium enrichment system. Tritium breeding cladding body and primary loop system pass through The fluid inlet and the fluid outlet are connected with two nozzles, and the primary loop system is connected with the tritium enrichment system through the steam outlet of its decompression gas-liquid separation device.

[0031] The system uses a heavy water saturated solution of lithium deuterium oxide as a tritium breeding agent and coolant, wherein the molar concentration of lithium deuterium oxide is between 5.5mol / l, the inlet temperature of the tritium breeding cladding body is 260°C, and the outlet temperature is 280°C. The working pressure is at 8MPa.

[0032] The primary circuit system consists of a voltage stabilizer, a heat exchanger, a pump, a decompression vap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com