Epitaxial structure, growth process and chip process of near-infrared light emitting diode

A technology of light-emitting diodes and epitaxial structures, applied in crystal growth, single crystal growth, electrical components, etc., can solve problems such as difficulty in meeting the high power requirements of near-infrared light-emitting diodes, low internal quantum efficiency of near-infrared diodes, and difficult breakthroughs in power. Achieve the effects of improving external quantum efficiency, increasing light output angle, and high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

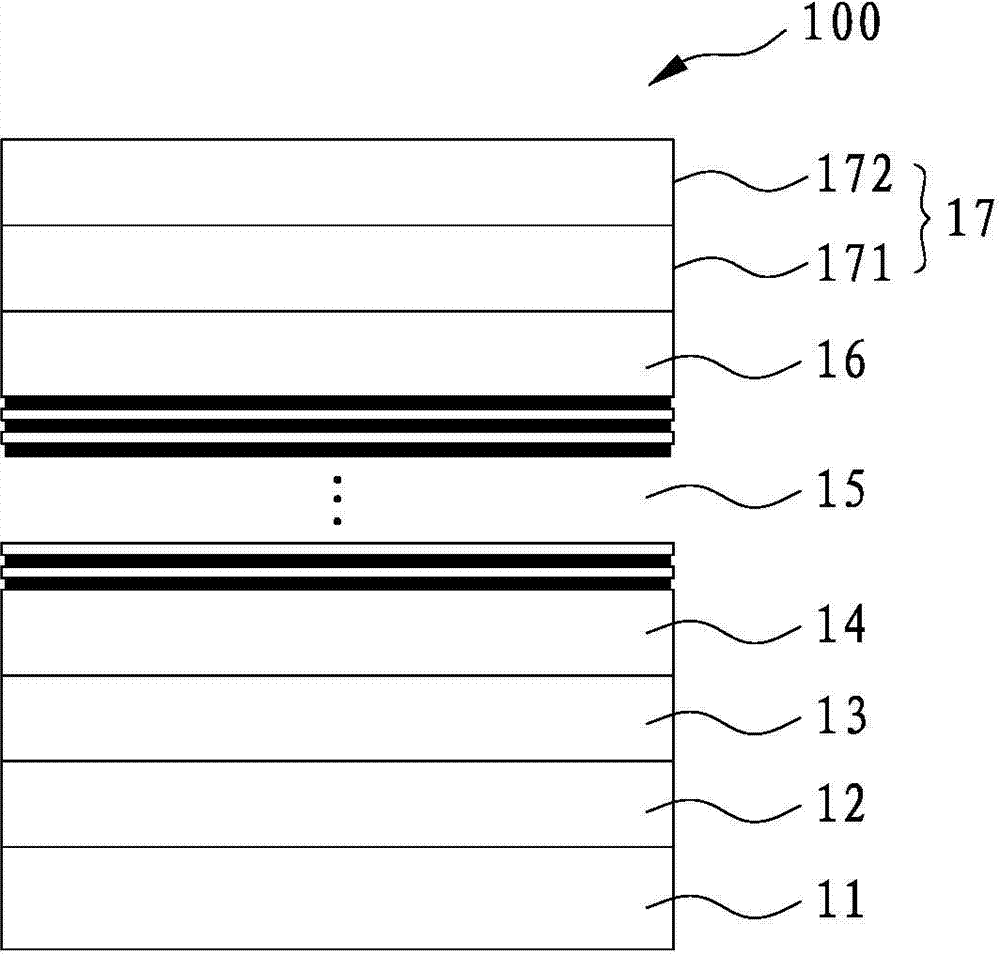

[0059] Such as figure 1 As shown in the first embodiment 100 of the epitaxial structure of a near-infrared light-emitting diode disclosed in the present invention, the cut-off layer 12, the first-type current spreading layer 13, the first-type confinement layer 14, the first-type confinement layer 14, and the The active layer 15 , the second-type confinement layer 16 , the second-type current spreading layer 17 , and the second-type current spreading layer 17 are composed of a first component 171 and a second component 172 .

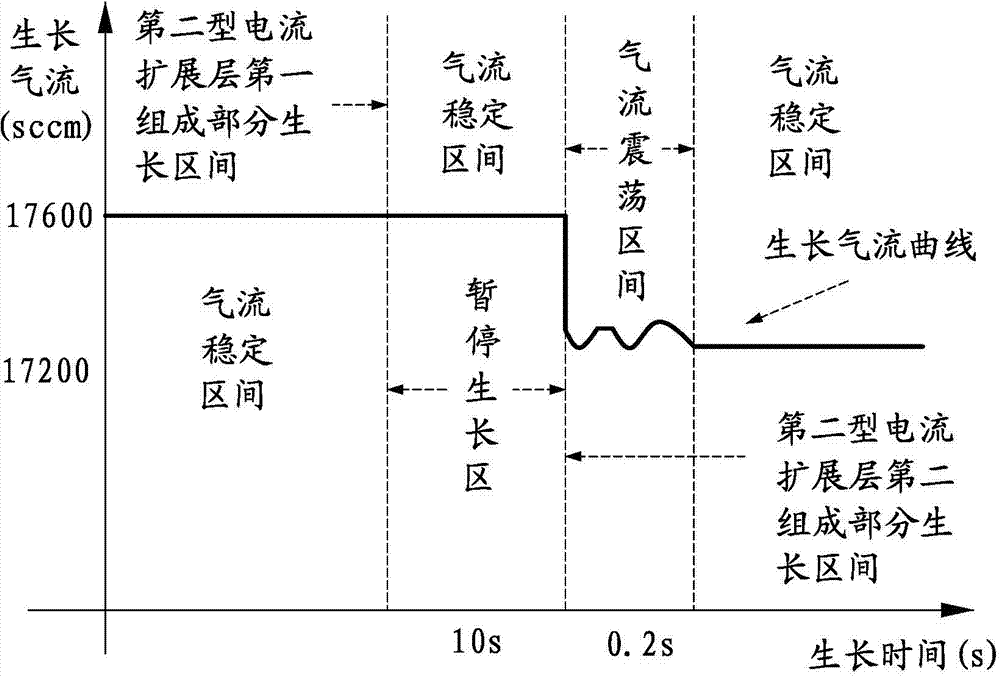

[0060] Wherein, the corrosion stop layer 12 is (Al 0.1 Ga 0.9 ) 0.5 In 0.5 Composed of P material; the active layer 15 adopts the quantum well structure of AlGaInAs / AlGaAs, the logarithm of the quantum well is 7 pairs, and the light emission wavelength is 850nm; Layer 14 and the second-type confinement layer 16 are made of AlGaAs material, and the first component 171 of the second-type current spreading layer is made of Al 0.1 Ga 0.9 As III-V compo...

Embodiment 2

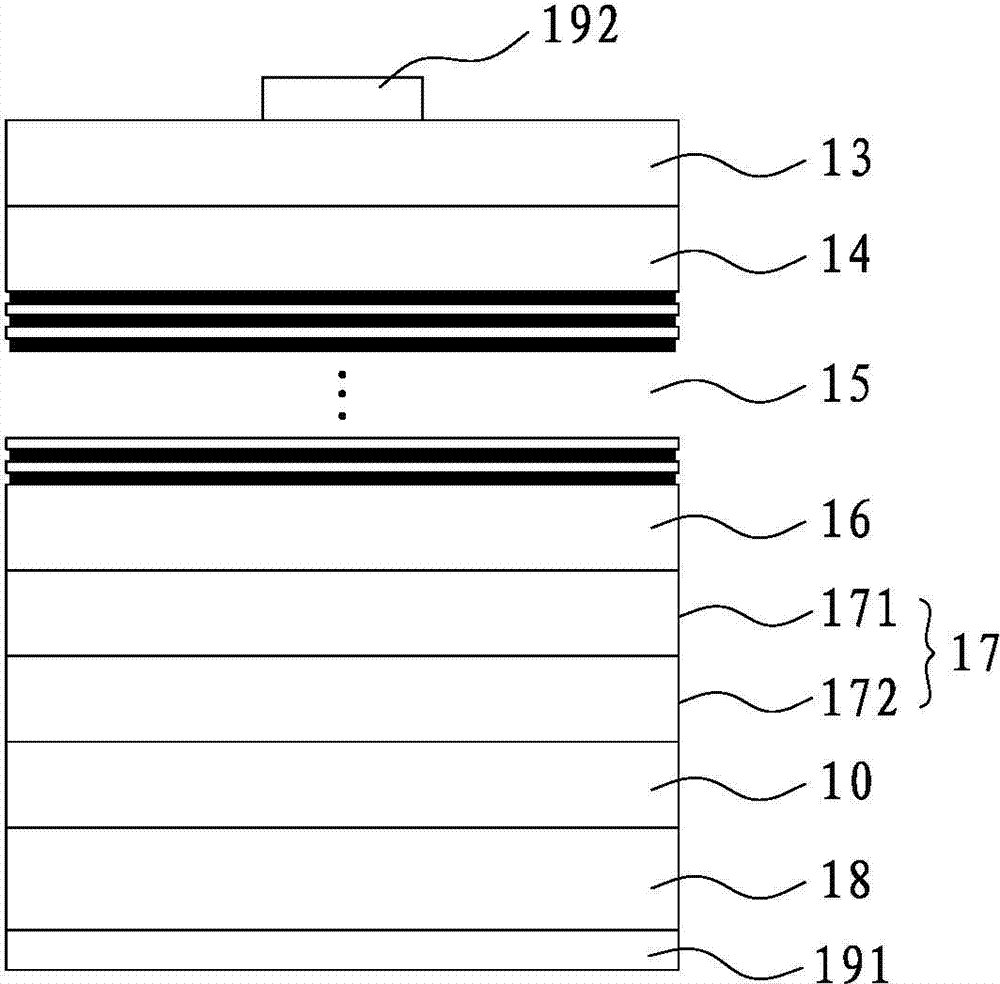

[0064] Such as Figure 4 Shown is the second embodiment 200 of the epitaxial structure of a near-infrared light-emitting diode disclosed by the present invention. On the GaAs substrate 21, the first-type current spreading layer 22, the first-type confinement layer 23, the active layer 24, the second The second-type confinement layer 25 , the second-type current spreading layer 26 , and the second-type current spreading layer 26 are composed of a first component 261 and a second component 262 .

[0065] Among them, the active layer 24 adopts the quantum well structure of AlGaInAs / AlGaAs, the logarithm of the quantum wells is 3 pairs, and the light emission wavelength is 850nm; the material of the first-type current spreading layer 22 is AlGaInP III-V compound, and the thickness is 8.5 μm , the first-type confinement layer 23 and the second-type confinement layer 25 are made of AlGaInP III-V compound, and the first component 261 of the second-type current spreading layer 26 is m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Luminous wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com