Multifunctional trail-type potato combine harvester

A combine harvester and harvester technology, which is applied in the direction of digging harvesters, collectors, harvesters, etc., can solve the problems of rising labor costs, technical complexity, and retention, and achieve strong moisture adaptability, improve the working environment, and work high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

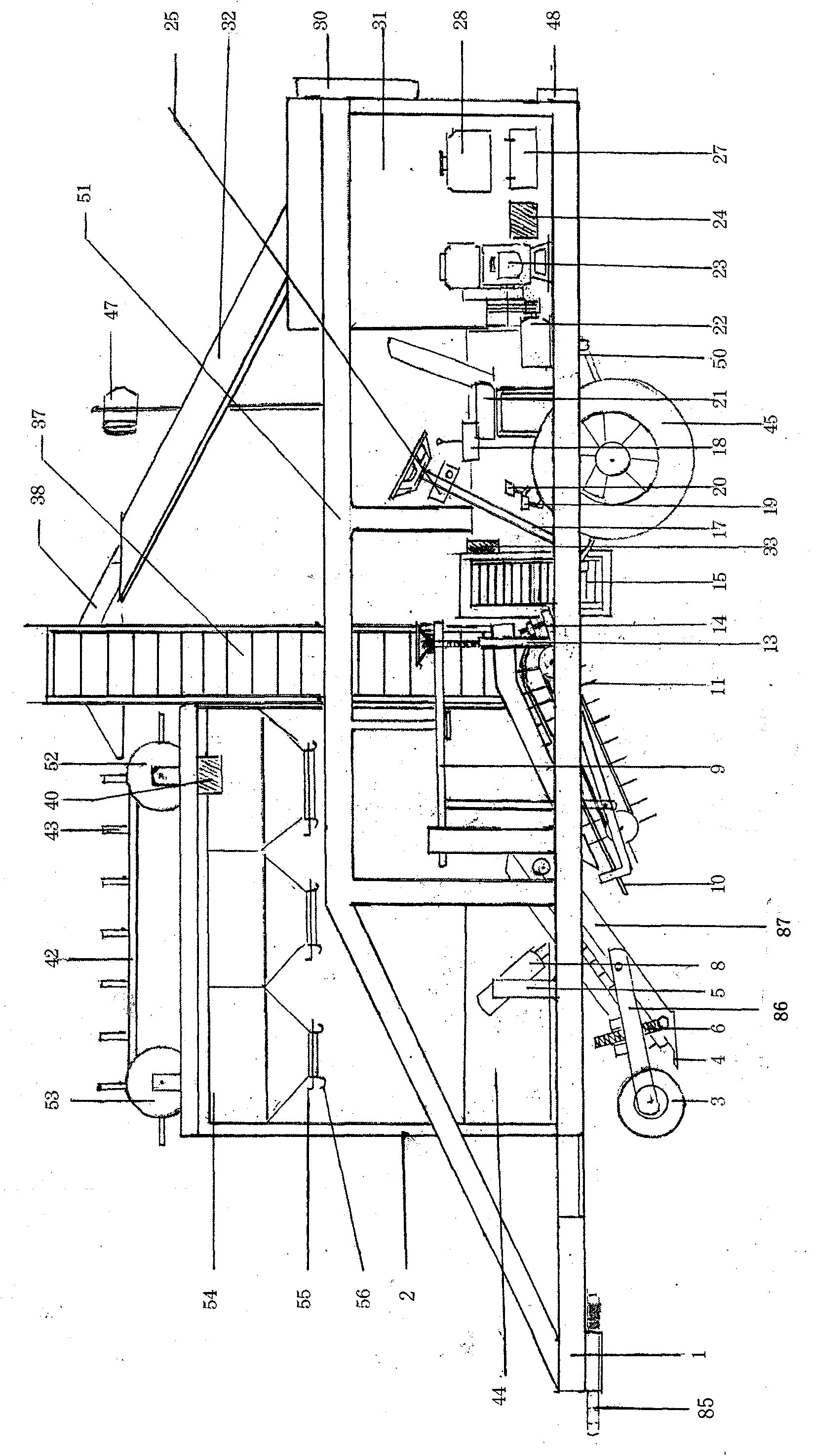

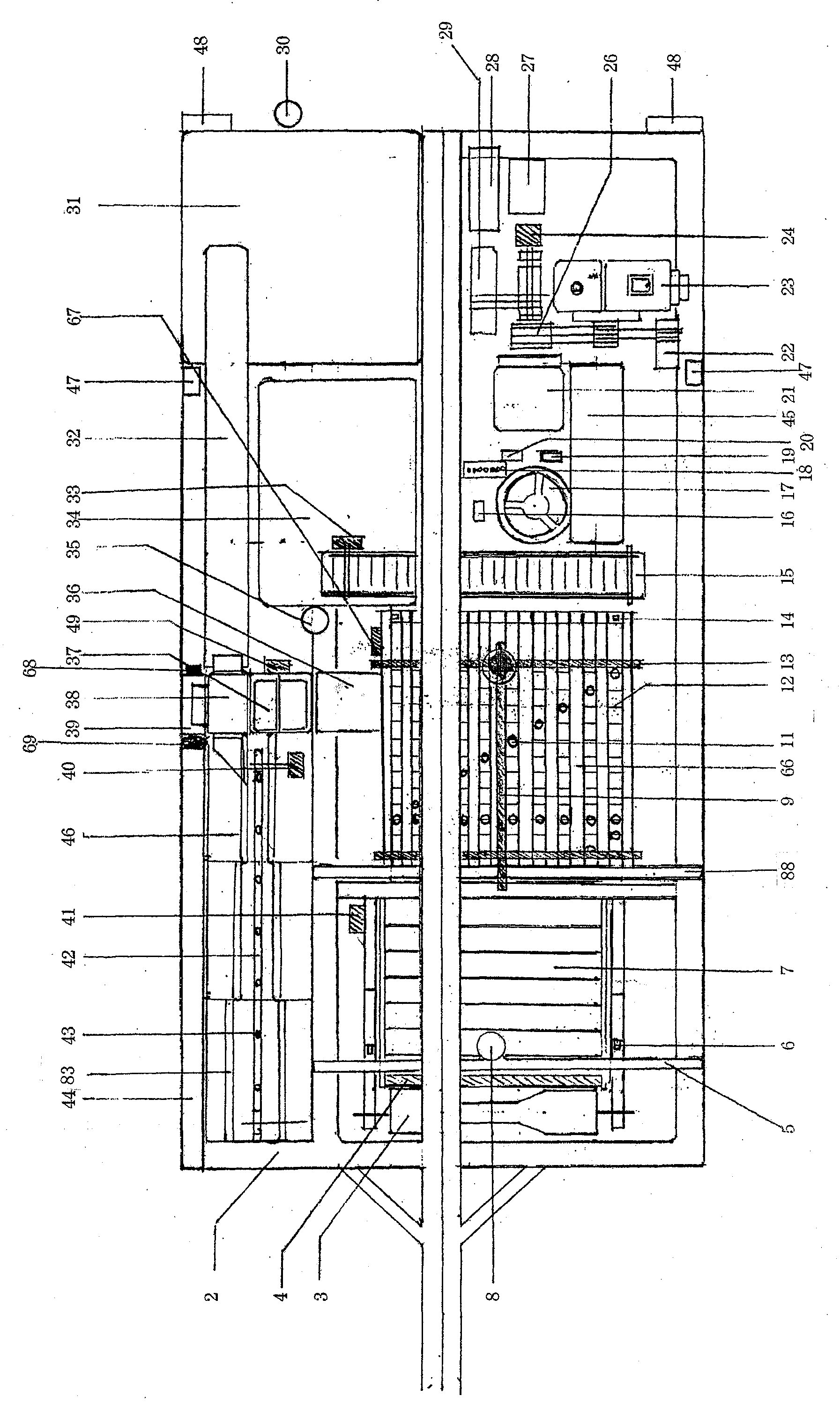

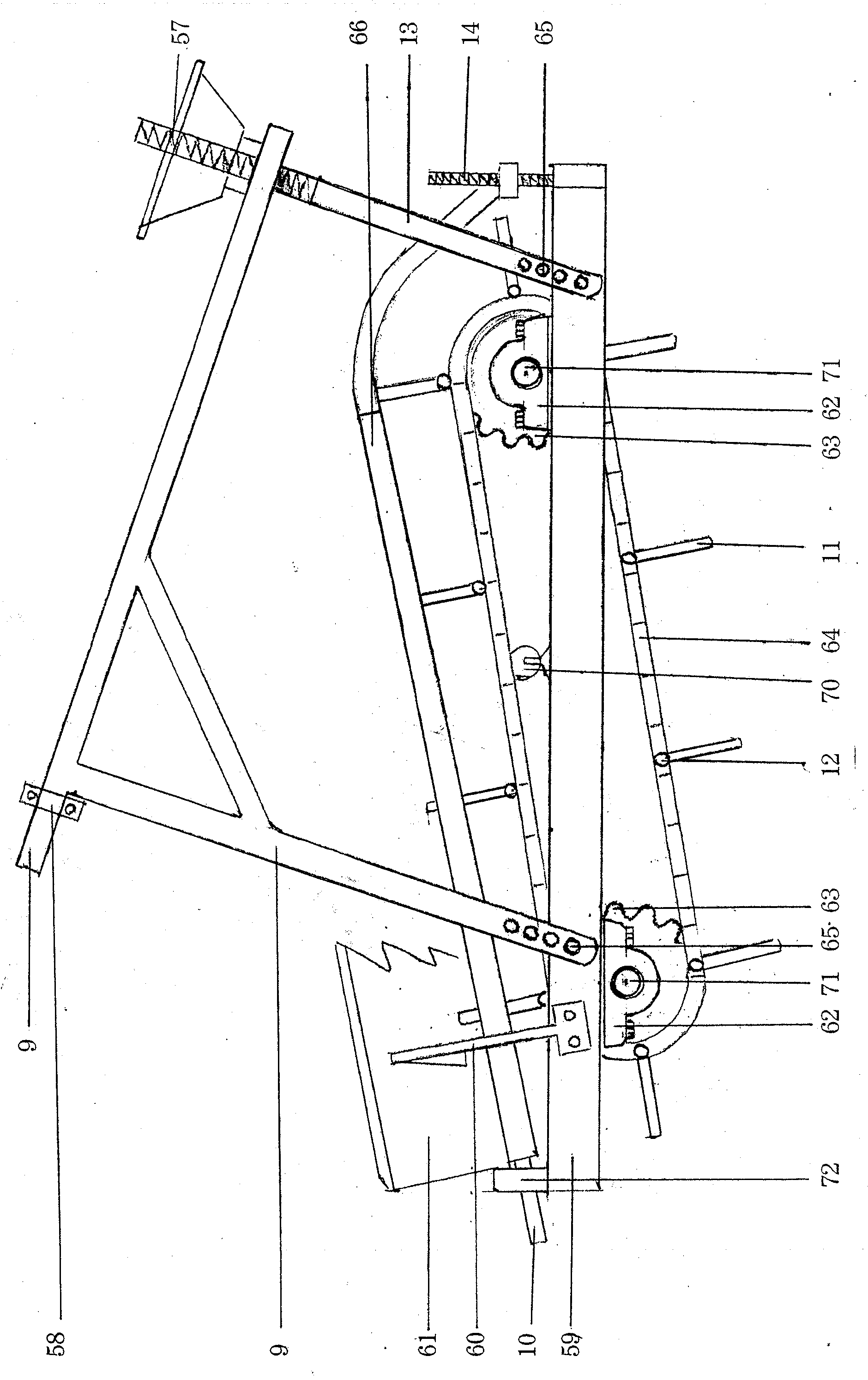

[0027] As shown in the figure, a traction-type potato multifunctional combined harvester is characterized in that the harvesting frame 1 is a rectangular frame, and there is an upward beam 51 on the rectangular harvesting frame 1 along the central axis, and the front part of the harvesting frame 1 Welded with a traction shaft 85, the lifting conveyor belt 7 is installed on the left front of the harvesting frame 1, the front portion of the lifting conveyor belt 7 is welded with a rectangular shovel plate 4, and the front portion of the rectangular shovel plate 4 is equipped with a profiling depth-limiting wheel 3. The wheel frame 86 is installed on the lifting conveyor belt frame 87, and is connected to the middle part of the depth limiting wheel frame 86 with two depth-limiting pull rods 6 on the left and right. The right side of the rear part of the lifting conveyor belt 7 is equipped with an excavation hydraulic motor 41, and the oil cylinder beam 5 is fixedly installed. On t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com