Processing method of coated sweet potato fudge in series of flavors and shapes

A processing method and technology of coated sweet potato, which is applied in the field of processing a series of flavors and shapes of coated sweet potato fudge, can solve the problems of only sticks in shape, single flavor, and monotony, and achieve the effect of diverse shapes, good palatability, and uniform quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

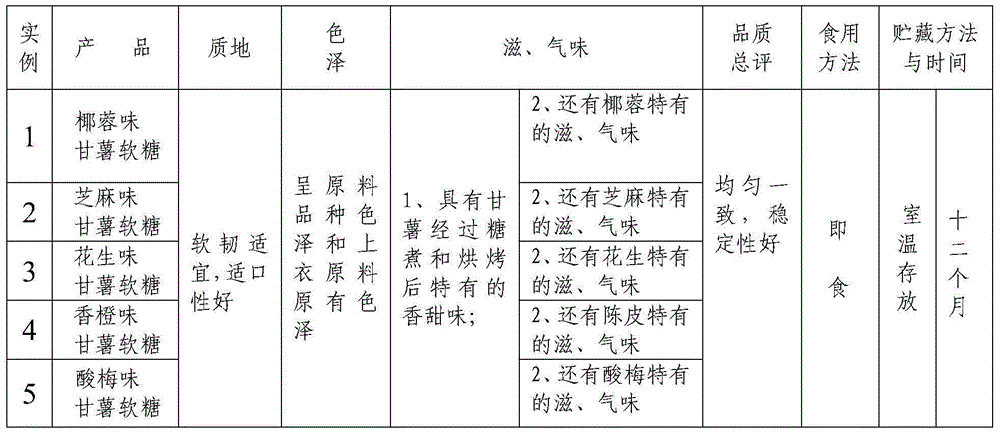

Examples

example 1

[0031] Choose fresh, plump, pest-free sweet potatoes as raw materials, peel them, soak them in water for 12 hours, wash, remove and drain; pour the drained raw materials into a sandwich pot and cook for 40 minutes until cooked; pour the steamed sweet potatoes while they are hot Put it into a colloid mill for beating and emulsification, and the emulsification fineness is 2um; take 160kg of sweet potato pulp and pour it into a 300L sandwich pot, pour the prepared auxiliary materials together, stir evenly, and prepare and cook the pulp. The cooking time is 45min. The auxiliary material formula described therein is: 60 kg of glucose syrup, 2.5 kg of honey, 2.5 kg of maltodextrin, 25 kg of drinking water, 1.5 kg of carrageenan, 80 g of sodium metabisulfite, 12 g of disodium edetate, and 20 g of potassium sorbate.

[0032] Pour the boiled slurry into a cake-shaped mold, blow and cool it in time with a fan, let the material embryo be fully solidified and formed, and after it has a cer...

example 2

[0034] Top coat ingredients are: fried black sesame or white sesame; the mold is in the shape of a gold ingot; other processes are the same as Example 1 to make sesame-flavored sweet potato fudge.

example 3

[0036] The top coat ingredients are: fried peanuts, crushed to a fineness of 20 meshes; the mold is spherical; other processes are the same as in Example 1 to make peanut-flavored sweet potato fudge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com