Integrated swimming self-circulation denitrification reactor

A reactor and self-circulation technology, which is applied in the field of biological denitrification reactors, can solve the problems of nitrite accumulation and difficult regulation, and achieve the effects of strengthening biological denitrification, promoting mass transfer and reaction, and improving volumetric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

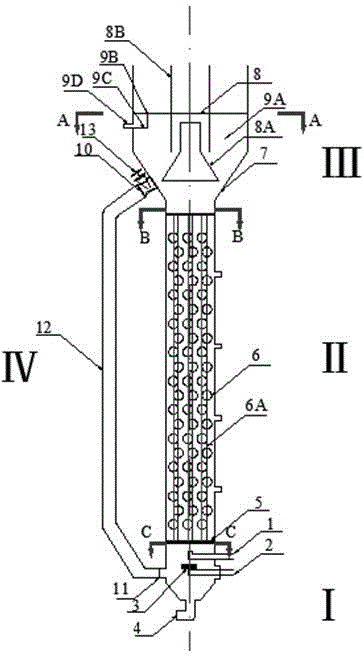

[0020] Such as figure 1 , 2 , 3, the body of the integrated swimming type self-circulation denitrification reactor is provided with water inlet area I, reaction area II, separation area III and circulation area IV; , air intake pipe 2, aeration head 3, and mud discharge pipe 4; the bottom of the reactor body is provided with a mud discharge pipe 4, and the lower part of the reactor body is provided with an aeration head 3, which is connected to the air intake pipe 2. 3 is provided with a water inlet pipe 1 above;

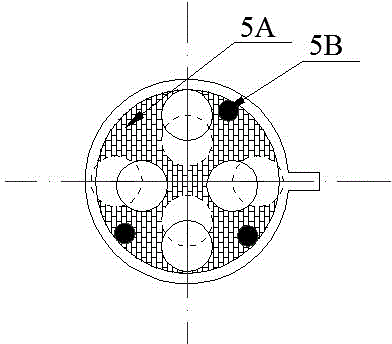

[0021] The reaction zone is located in the middle of the reactor body and is mainly composed of filler brackets 5 and staggered and fixed hollow balls 6 fillers. The middle of the reactor body is provided with staggered and fixed hollow balls 6, and the lower end of the middle of the reactor body is provided with a filler bracket 5;

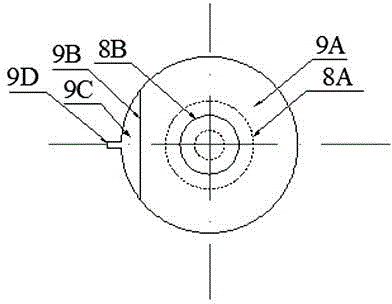

[0022] The separation zone is located at the upper part of the reactor body, and mainly consists of a gradual expansion zone 7, a g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com