Method for preparing polyoxymethylene dimethylethers from methanol and formaldehyde

A polymethoxydimethyl ether and methanol technology, which can be used in chemical instruments and methods, preparation of organic compounds, metal/metal oxide/metal hydroxide catalysts, etc., and can solve problems such as unsatisfactory selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

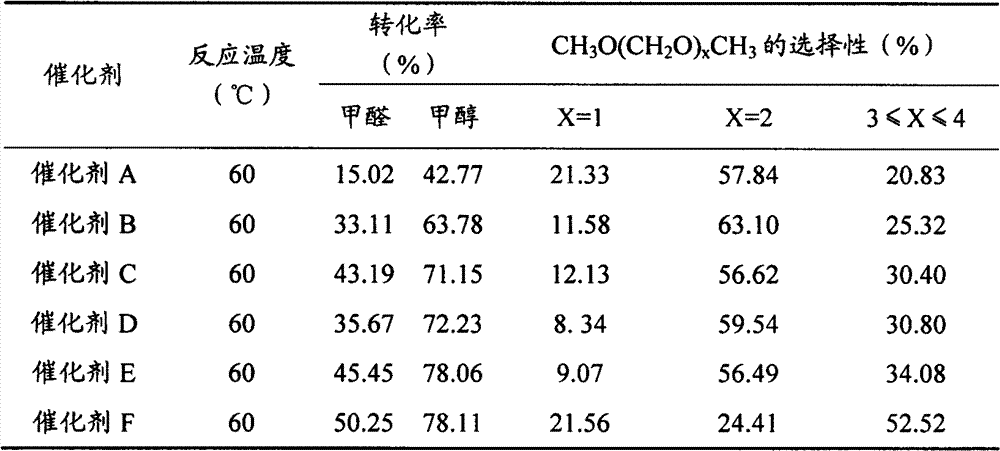

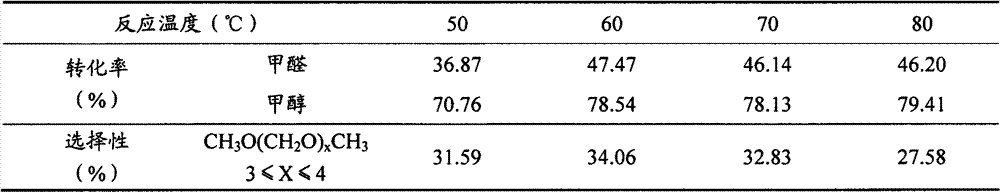

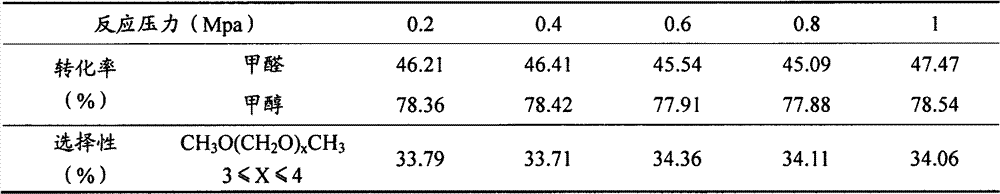

Examples

preparation example Construction

[0010] (1) Carrier (γ-Al 2 o 3 ) preparation:

[0011] Prepare aluminum sulfate in water at 60°C to 70°C to make an aqueous solution with a relative density of 1.21 to 1.23, and at the same time prepare Na with a mass percentage of 20%. 2 CO 3 aqueous solution;

[0012] Under the condition of 50 ℃ ~ 60 ℃, the aluminum sulfate aqueous solution with a relative density of 1.21 ~ 1.23 and 20% by mass percent of Na 2 CO 3 The aqueous solution is mixed, there is precipitation, filter, and the filter cake is washed with distilled water at a temperature of 50 ° C to 60 ° C until the washing liquid does not contain SO 4 2- ions (can pass Ba 2+ detection);

[0013] Put the washed filter cake in ammonia water with a temperature of 50°C-60°C and a pH value of 9.0-11.0, let it stand for at least 4 hours (curing), filter, and use distilled water at a temperature of 50°C-60°C again for the filter cake Wash until the specific resistance of the washing liquid is greater than 200 Ω / cm,...

Embodiment 1

[0023] Carrier (γ-Al 2 o 3 ) preparation:

[0024] Prepare aluminum sulfate in water at 60°C to 70°C to make an aqueous solution with a relative density of 1.21 to 1.23, and at the same time prepare Na with a mass percentage of 20%. 2 CO 3 aqueous solution;

[0025] Under the condition of 50 ℃ ~ 60 ℃, the aluminum sulfate aqueous solution with a relative density of 1.21 ~ 1.23 and 20% by mass percent of Na 2 CO 3 The aqueous solution is mixed, there is precipitation, filter, and the filter cake is washed with distilled water at a temperature of 50 ° C to 60 ° C until the washing liquid does not contain SO 4 2- ions (can pass Ba 2+ detection);

[0026] Put the washed filter cake in ammonia water with a temperature of 50°C-60°C and a pH value of 9.0-11.0, let it stand for at least 4 hours (curing), filter, and use distilled water at a temperature of 50°C-60°C again for the filter cake Washing until the specific resistance of the washing liquid is greater than 200Ω / cm, t...

Embodiment 2

[0028] Take by weighing 5 grams of carrier (γ-Al 2 o 3 ), it was impregnated into 20 (mass)% ammonium molybdate solution, impregnated at a constant temperature of 60°C for 6h, then dried at 120°C for 12h, and then roasted for 6h in an air atmosphere and at 400°C to obtain the target catalyst (abbreviated It is catalyst A): wherein the content of metal molybdenum and / or its oxide is 8 (mass)%, and the balance is carrier (γ-Al 2 o 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com