Carbonyl starch oxidized by Fenton similar system, and preparation method of carbonyl starch

A carbonyl starch and system technology, applied in the field of carbonyl starch and its preparation, can solve the problems of high production cost, poor starch oxidation selectivity, and low oxidation efficiency, and achieve high carbonyl content, strong oxidation ability, and high oxidation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

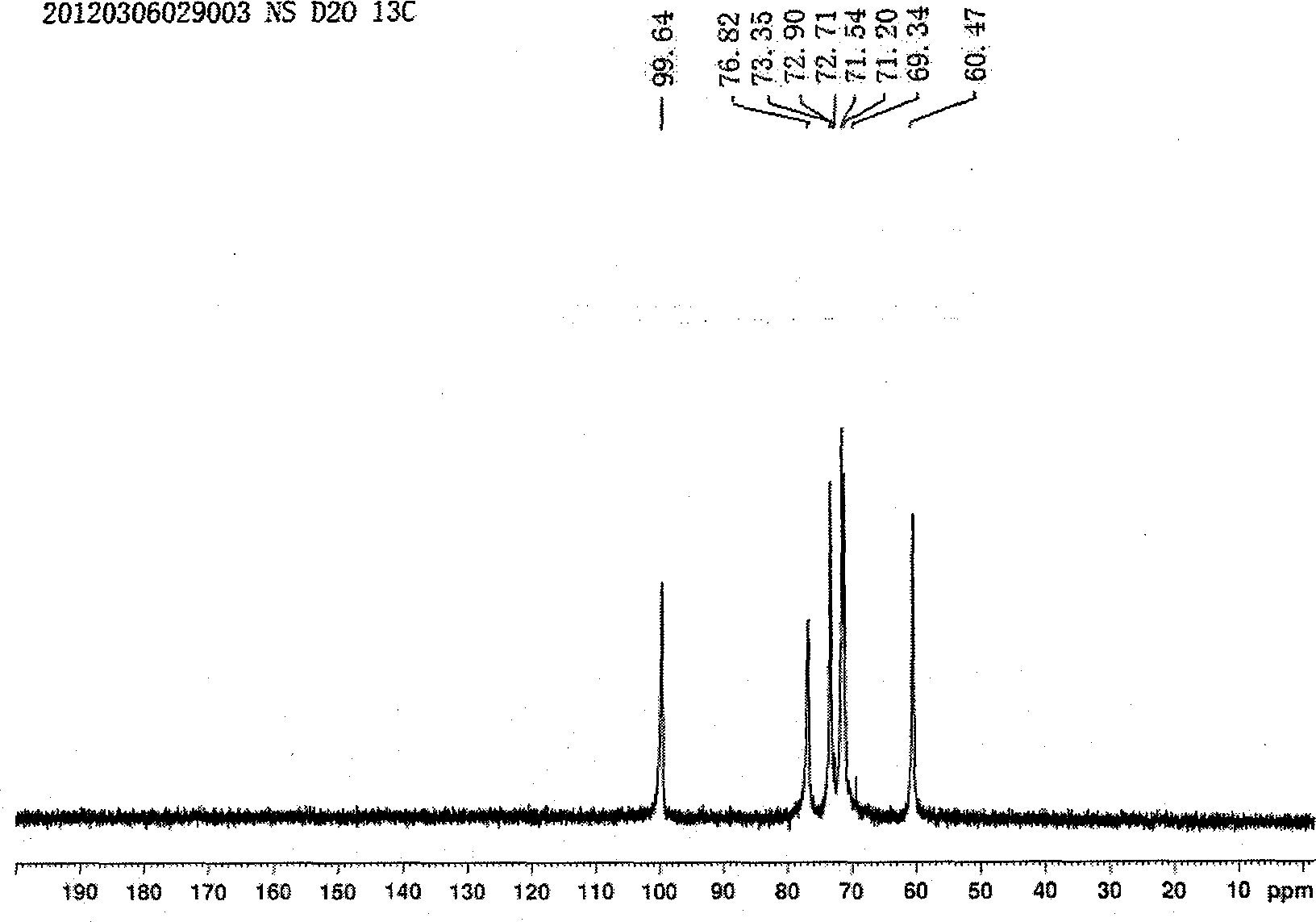

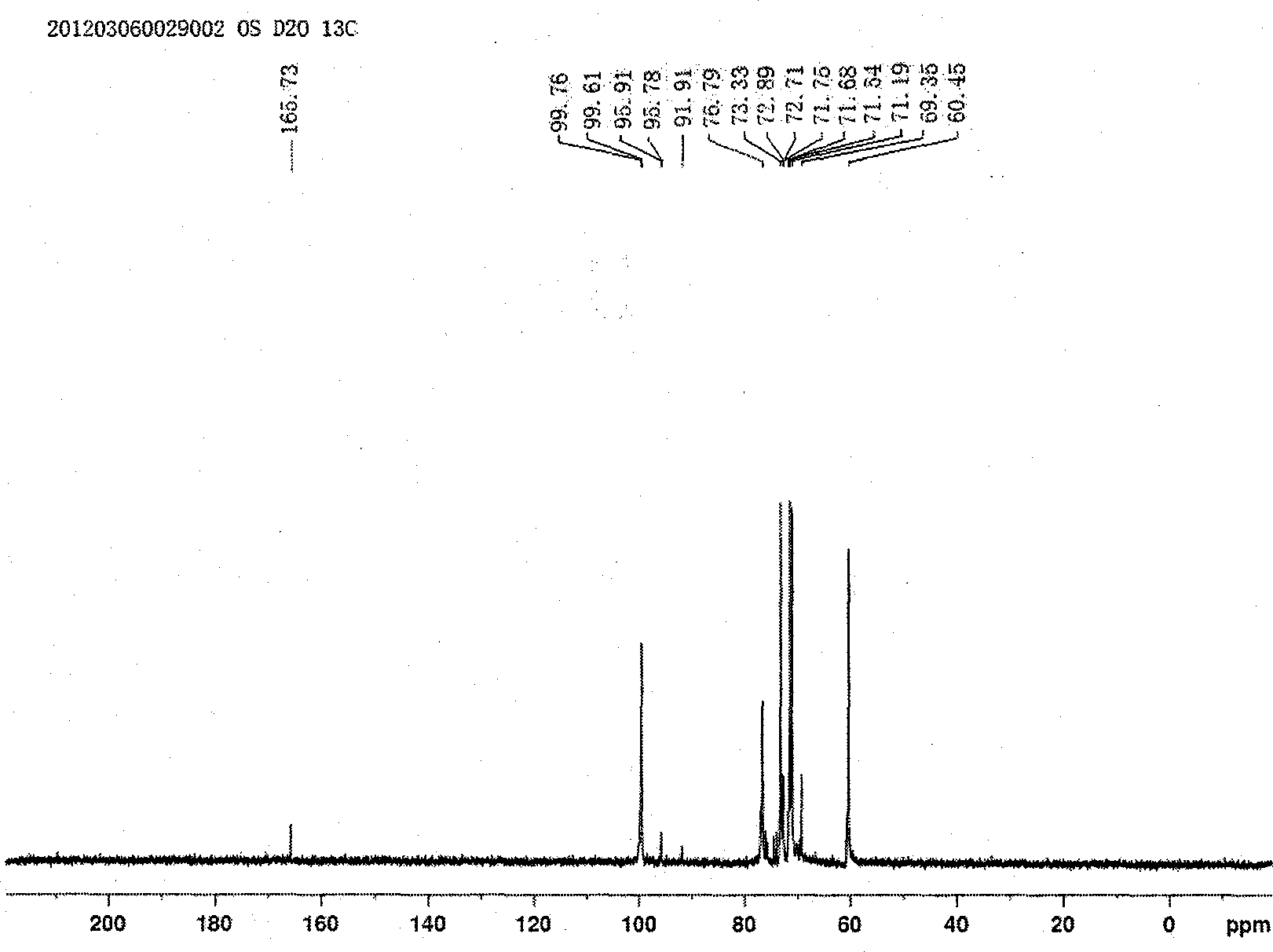

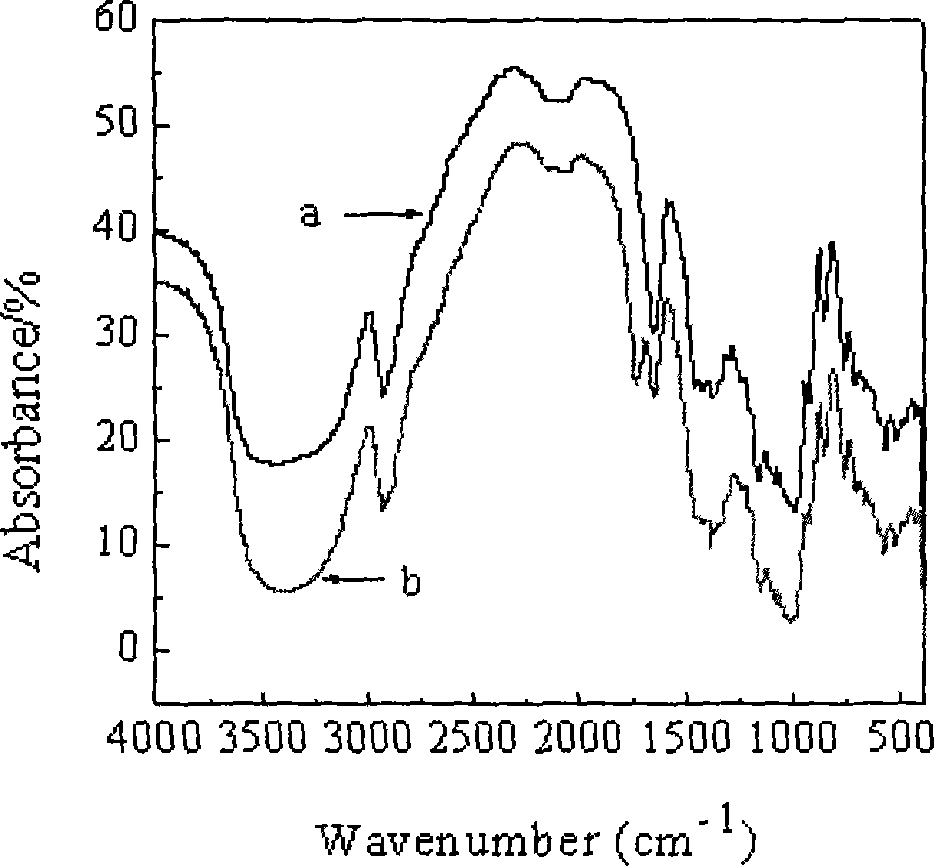

Embodiment 1

[0033]Take a certain amount of corn starch and add it to a three-necked bottle, add distilled water to prepare a 40wt% starch suspension, heat and gelatinize in a water bath at 65°C for 1 hour, and add cerium nitrate (2wt% ), cuprous sulfate (0.008wt%), adjust the pH of the reaction solution to 3.0, keep the temperature at 35°C, slowly add hydrogen peroxide (12wt%) dropwise after 12 hours, and suction filter after stirring and reacting for 6 hours at 40°C. The cake was washed with acetone and dried in a vacuum oven at 60°C to obtain the product. The measured carbonyl content of the product is 13.40%, and the carboxyl content is 3.10%.

Embodiment 2

[0035] Take a certain amount of corn starch and add it to a three-necked bottle, add distilled water to prepare a 40wt% starch suspension, heat and gelatinize it in a water bath at 65°C for 1 hour, and add cerium nitrate (1wt% ), cuprous sulfate (0.008wt%), adjust the pH of the reaction solution to 3.0, keep the temperature at 35°C, slowly add hydrogen peroxide (12wt%) dropwise after 12 hours, and suction filter after stirring and reacting for 6 hours at 40°C. The cake was washed with acetone and dried in a vacuum oven at 60°C to obtain the product. The measured carbonyl content of the product is 10%, and the carboxyl content is 5.80%.

Embodiment 3

[0037] Take a certain amount of corn starch and add it to a three-necked bottle, add distilled water to prepare a 40wt% starch suspension, heat and gelatinize in a water bath at 65°C for 1 hour, and add cerium nitrate (3wt% ), ferrous sulfate (0.005wt%), adjust the pH of the reaction solution to 3.0, keep the temperature at 35°C, slowly add hydrogen peroxide (10wt%) dropwise after 12 hours, and suction filter after stirring and reacting for 6 hours at 40°C. The cake was washed with acetone and dried in a vacuum oven at 60°C to obtain the product. The measured carbonyl content of the product is 15.94%, and the carboxyl content is 2.99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com