Preparation method of polyamide-amine dendritic compound

A technology of amine dendrimers and polyamides, which is applied in the field of preparation of polyamide-amine dendrimers, can solve problems such as waste of raw materials, influence on product purity, and incomplete separation of products, and achieve high yield and high purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

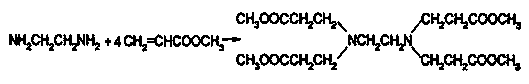

[0016] Preparation of semi-algebraic PAMAM G0.5. Take a certain amount of MA methanol solution in a three-necked flask, and a certain amount of EDA methanol solution in a constant pressure dropping funnel. One side of the three-necked flask is connected to a constant pressure dropping funnel, and the other side is connected to a mercury thermometer. Connect a spherical condenser, where the molar ratio of MA to EDA end groups is 3:1. The three-neck flask was placed in a constant temperature water bath, and the EDA solution was added dropwise at a water bath temperature of 20±2°C with stirring. After 24 hours of reaction, the water bath temperature was 40±1°C, the condensation temperature was -8 ~ -15°C, and the vacuum degree was 80KPa. distilled. When the condensate is obviously reduced, the temperature of the distilled water bath is 46±1°C, and the vacuum degree is 98KPa to continue the vacuum distillation to remove the residual methanol and MA. The finally obtained light yel...

Embodiment 2

[0018] Preparation of semi-algebraic PAMAM G0.5. Take a certain amount of MA methanol solution in a three-necked flask, and a certain amount of EDA methanol solution in a constant pressure dropping funnel. One side of the three-necked flask is connected to a constant pressure dropping funnel, and the other side is connected to a mercury thermometer. Connect a spherical condenser, where the molar ratio of MA to EDA end groups is 1.5:1. The three-neck flask was placed in a constant temperature water bath, and the EDA solution was added dropwise at a water bath temperature of 22±2°C with stirring. After 24 hours of reaction, the water bath temperature was 40±1°C, the condensation temperature was -13 to -18°C, and the vacuum degree was 85KPa. distilled. When the condensate is significantly reduced, the temperature of the distilled water bath is 56±1°C, and the vacuum is 100KPa to continue vacuum distillation to remove residual methanol and MA. The final light yellow product is th...

Embodiment 3

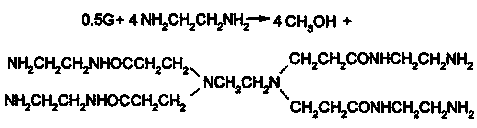

[0020] Preparation of Integer Algebraic PAMAM G1.0. Take a certain amount of methanol solution of EDA in a three-necked flask, a certain amount of methanol solution of PAMAM G0.5 in a constant pressure dropping funnel, one side of the three-necked flask is connected to a constant pressure dropping funnel, and the other side is connected to a mercury thermometer , the middle port is connected with a spherical condenser, and the molar ratio of EDA to PAMAM G0.5 end group is 4:1. The three-neck flask was placed in a constant temperature water bath, and PAMAM G0.5 solution was added dropwise at a water bath temperature of 25±2°C with stirring. After 24 hours of reaction, the water bath temperature was 56±1°C, the condensation temperature was -10 to -15°C, and the vacuum degree was 90KPa. Distill under reduced pressure. When the condensate is significantly reduced, the temperature of the distilled water bath is 68±1°C, and the vacuum distillation is continued at 100KPa to remove t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com