Submerged pump cable rubber sheath rubber composition

A technology of rubber composition and rubber sheath, which is applied in the direction of insulated cables, rubber insulators, cables, etc., can solve the problems of rough surface of the sheath, poor bending performance, no high temperature resistance mechanical properties, etc., and achieve good phase state and uniformity The effect of distribution, high mechanical strength, and high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

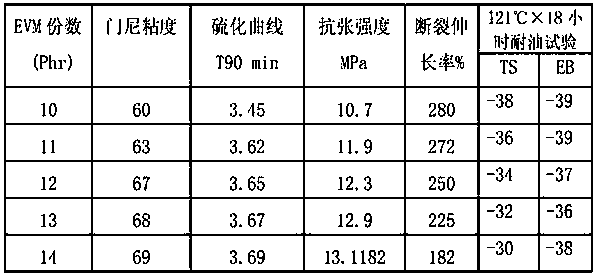

Embodiment 1

[0030] Put 100 parts of ethylene-propylene rubber and 10 parts of EVM into the internal mixer for internal mixing, and then put in water-resistant agent resin P-50, nano-scale zinc oxide, industrial stearic acid, silane coupling agent A-172, silane modified Calcined clay, peroxide curing agent were mixed for 4-5 minutes. After mixing, the mixed rubber is moved to an open mill for further processing. After the rubber is milled, filter the rubber. After filtering the glue, it is moved to the forming machine for rolling and slicing.

Embodiment 2

[0032] Put 100 parts of ethylene-propylene rubber and 11 parts of EVM into the internal mixer for internal mixing, and then put in water-resistant agent resin P-50, nano-scale zinc oxide, industrial stearic acid, silane coupling agent A-172, silane modified Calcined clay, peroxide curing agent were mixed for 4-5 minutes. After mixing, the mixed rubber is moved to an open mill for further processing. After the rubber is milled, filter the rubber. After filtering the glue, it is moved to the forming machine for rolling and slicing.

Embodiment 3

[0034] Put 100 parts of ethylene propylene rubber and 12 parts of EVM into the internal mixer for internal mixing, and then put in water-resistant agent resin P-50, nano-scale zinc oxide, industrial stearic acid, silane coupling agent A-172, silane modified Calcined clay and peroxide vulcanizing agent are mixed. After mixing, the mixed rubber is moved to an open mill for further processing. After the rubber is milled, filter the rubber. After filtering the glue, it is moved to the forming machine for rolling and slicing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com