Lithium bromide absorption liquid with carbon nano tube disperse system and preparation method thereof

A lithium bromide absorption and carbon nanotube technology, applied in the field of lithium bromide absorption liquid and its preparation, can solve the problems of low heat exchange efficiency and easy blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation of embodiment 1 lithium bromide absorbing liquid

[0035] (1) Preparation of lithium bromide aqueous solution

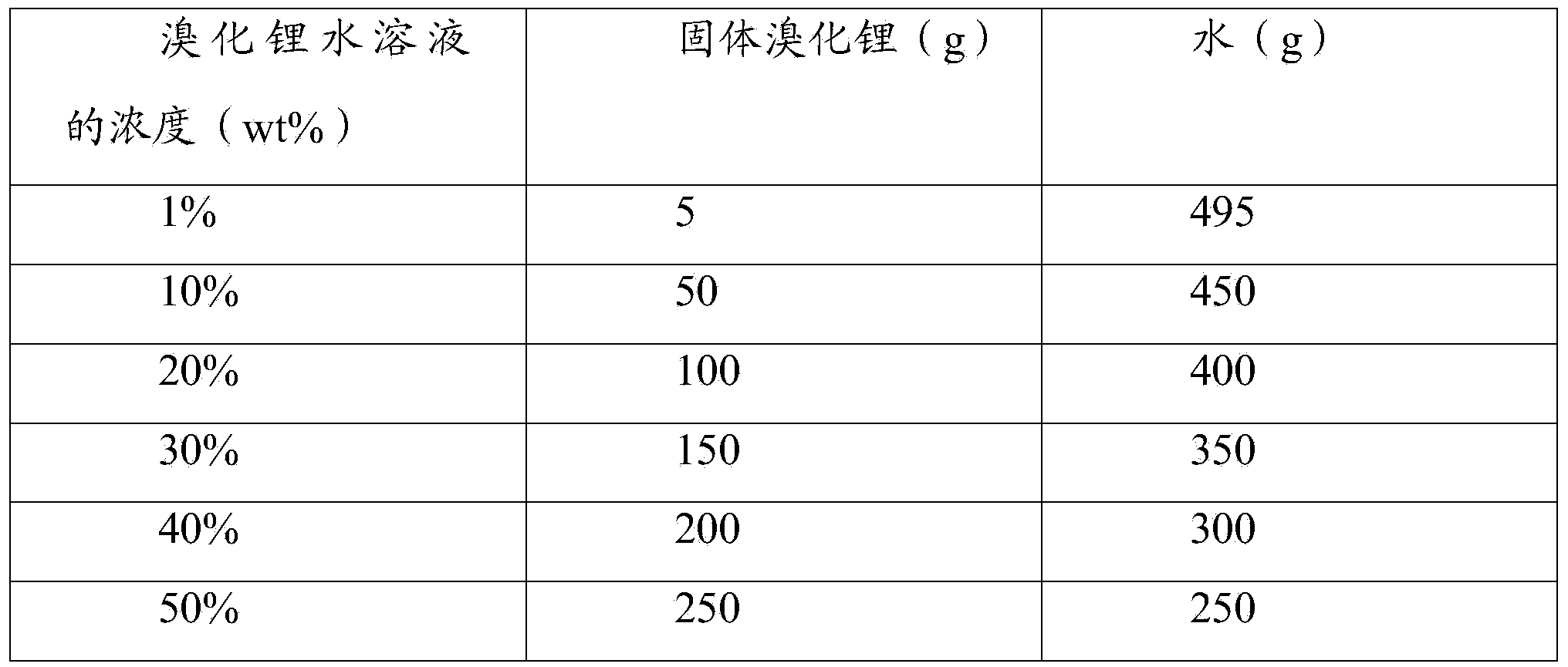

[0036] Prepare lithium bromide absorbing solutions with concentrations of 1wt%, 10wt%, 20wt%, 30wt%, 40wt%, and 50wt%. The proportioning of lithium bromide and water is carried out according to Table 1.

[0037] The component distribution ratio of table 1 lithium bromide aqueous solution

[0038]

[0039] (2) Obtaining carbon nanotubes

[0040] Carbon nanotubes can be purchased or prepared by yourself.

[0041] (3) Add carbon nanotube particles to the above-mentioned lithium bromide aqueous solution with various mass concentrations, so that the proportion of carbon nanotube particles contained in the lithium bromide absorption solution is 0.001wt%, 0.005wt%, 0.01wt%, and 36 batches are prepared. Perform ultrasonic dispersion treatment; then add octanol and amino alcohol complex titanate for further mixing and continue ultrasonic dispersion...

Embodiment 2

[0044] Long-term change of embodiment 2 lithium bromide absorbing liquid dispersion stability

[0045] (1) Preparation of lithium bromide aqueous solution

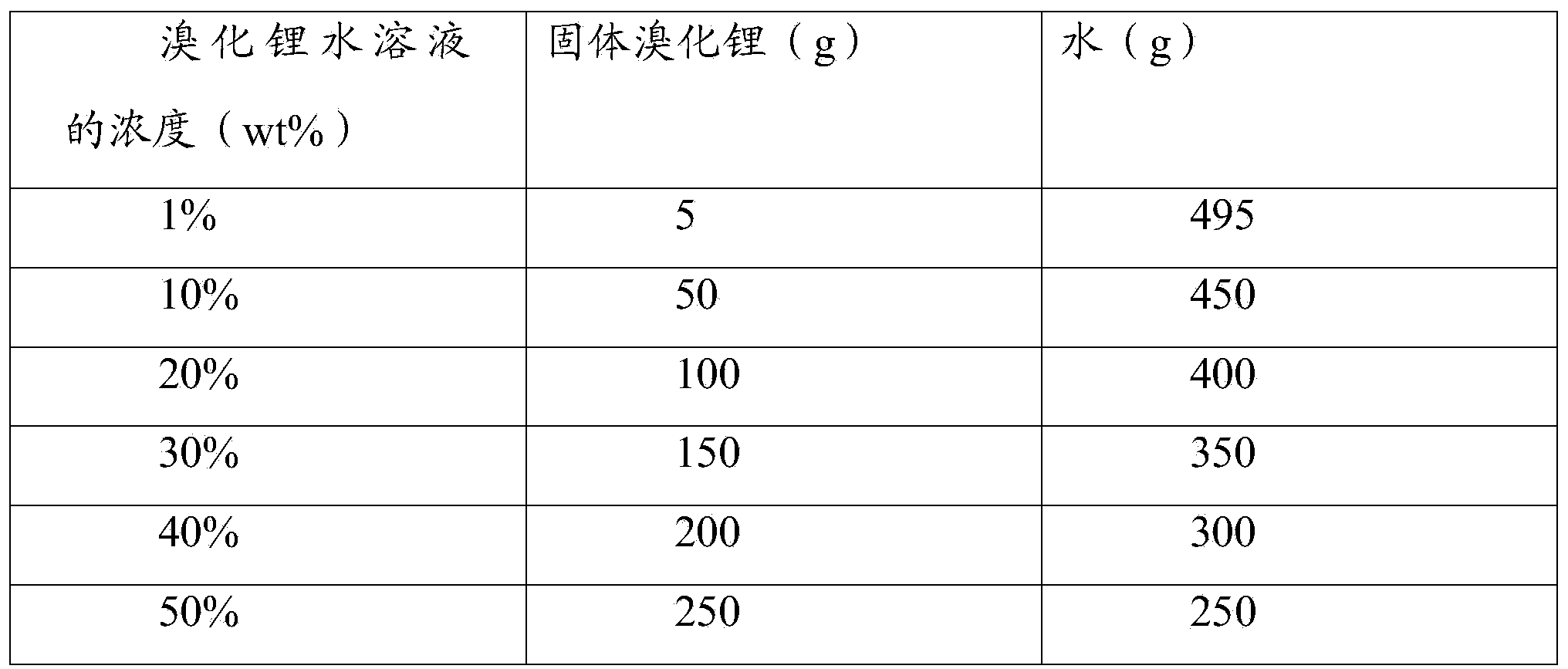

[0046] The concentration of the prepared lithium bromide aqueous solution is 1wt%, 10wt%, 20wt%, 30wt%, 40wt%, 50wt%. The proportioning of lithium bromide and water is carried out according to Table 1.

[0047] The component distribution ratio of table 1 lithium bromide aqueous solution

[0048]

[0049] (2) Obtaining carbon nanotubes

[0050] Carbon nanotubes can be purchased or prepared by yourself.

[0051] (3) Add carbon nanotube particles to the above-mentioned lithium bromide aqueous solutions with various mass concentrations, so that the proportion of carbon nanotube particles contained in the lithium bromide absorption solution is 0.001wt%, 0.004wt%, 0.01wt%, and 36 batches are prepared. Perform ultrasonic dispersion treatment; then add octanol and amino alcohol complex titanate for further mixing and contin...

Embodiment 3

[0054] Embodiment 3 Lithium Bromide Absorption Liquid Thermal Conductivity Variation

[0055] The following samples similar to those of Example 1 were prepared. That is, respectively disperse 0.01wt% of carbon nanotube microparticles, the solution concentration of lithium bromide aqueous solution is 50%, add 0.1wt% of amino alcohol complex titanate as a dispersion stabilizer to it, and prepare 6 ultrasonically dispersed sample.

[0056] The heat conduction and material conduction characteristics of the above-prepared samples were evaluated. The increase of the absorption rate when using lithium bromide absorption solution at different concentrations is studied relative to the absorption rate of general lithium bromide aqueous solution. When the absorptivity exceeds 1, an increase in the conductivity of the substance can be observed. The higher the concentration of nanoparticles, the greater the enhancement of the material conduction properties.

[0057] Compared with the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pipe diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com