Safety control method for vertical shaft grab bucket hoisting system and control system of same

The technology of a hoisting system and a control system is applied in the field of equipment to ensure the safe operation of hoisting machinery. The effect of illegal operation and command of heavy lifting operations, avoiding obstruction of lifting operations, and improving operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

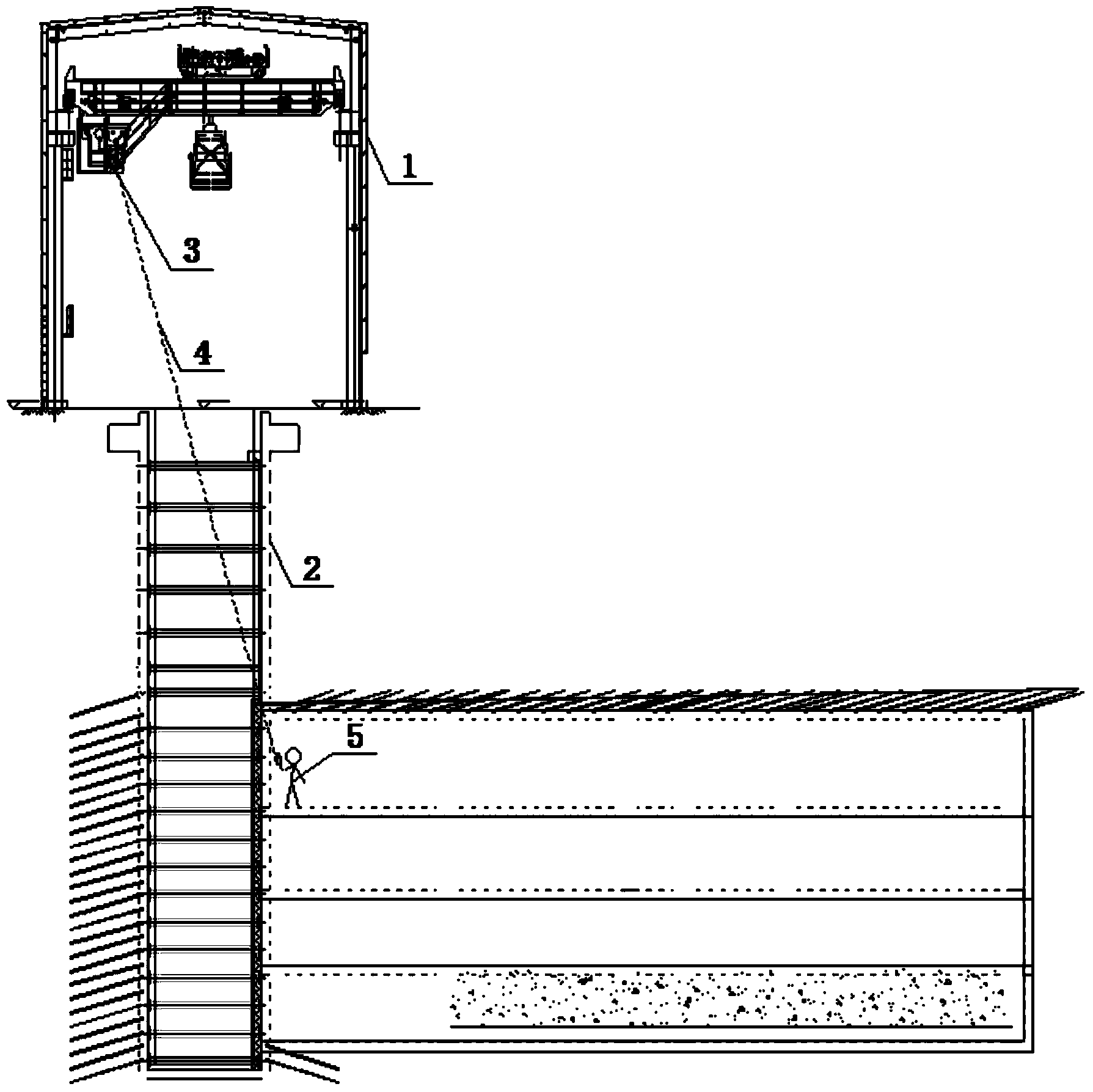

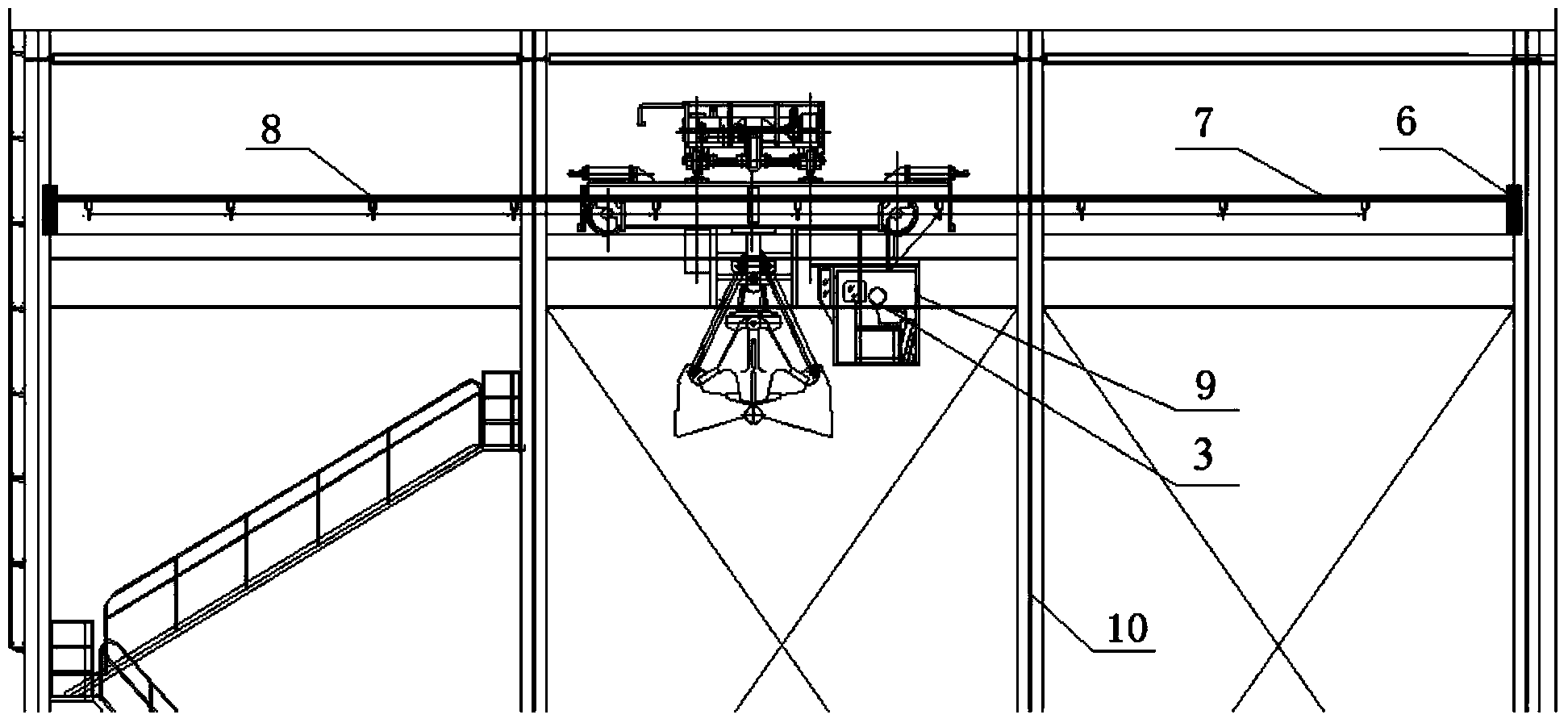

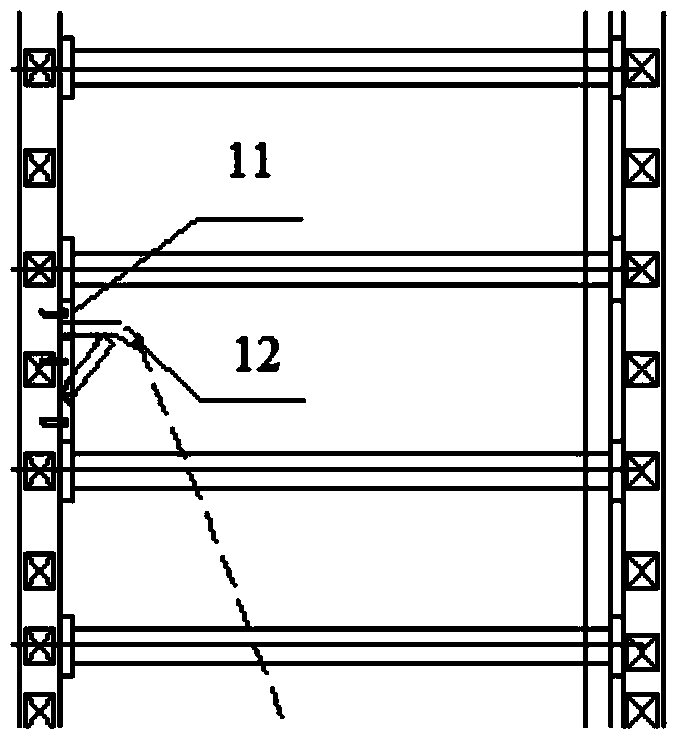

[0029] Such as Figure 1 to Figure 5 As shown, the safety control method of the vertical shaft grab lifting system of the present invention transmits the construction site image of the grab lifting system 1 through the video monitoring device, so that the driver 3 who controls the grab lifting system 1 can grasp the construction site in time Situation: In the video monitoring device, the construction site image is recorded by the video camera 12 that drives the crane operation of the grab hoisting system 1, and the construction site image recorded by the video camera 12 is transmitted to the screen divider and the video line in sequence. Monitor 9 ; the monitor 9 is located within the horizontal visual range of the driver 3 .

[0030] Such as figure 1 and Figure 5As shown, in the above-mentioned safety control method of the vertical shaft grab lifting system, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com