Bean packing bag and application for production of fresh bean sprouts

A packaging bag and bean sprouts technology, which is applied in the field of bean sprouts production, can solve the problems of inconvenient operation, uncertainty of the source of beans, and impact on health, and achieve the effect of easy portability, simple operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] 1. Production of soybean sprouts

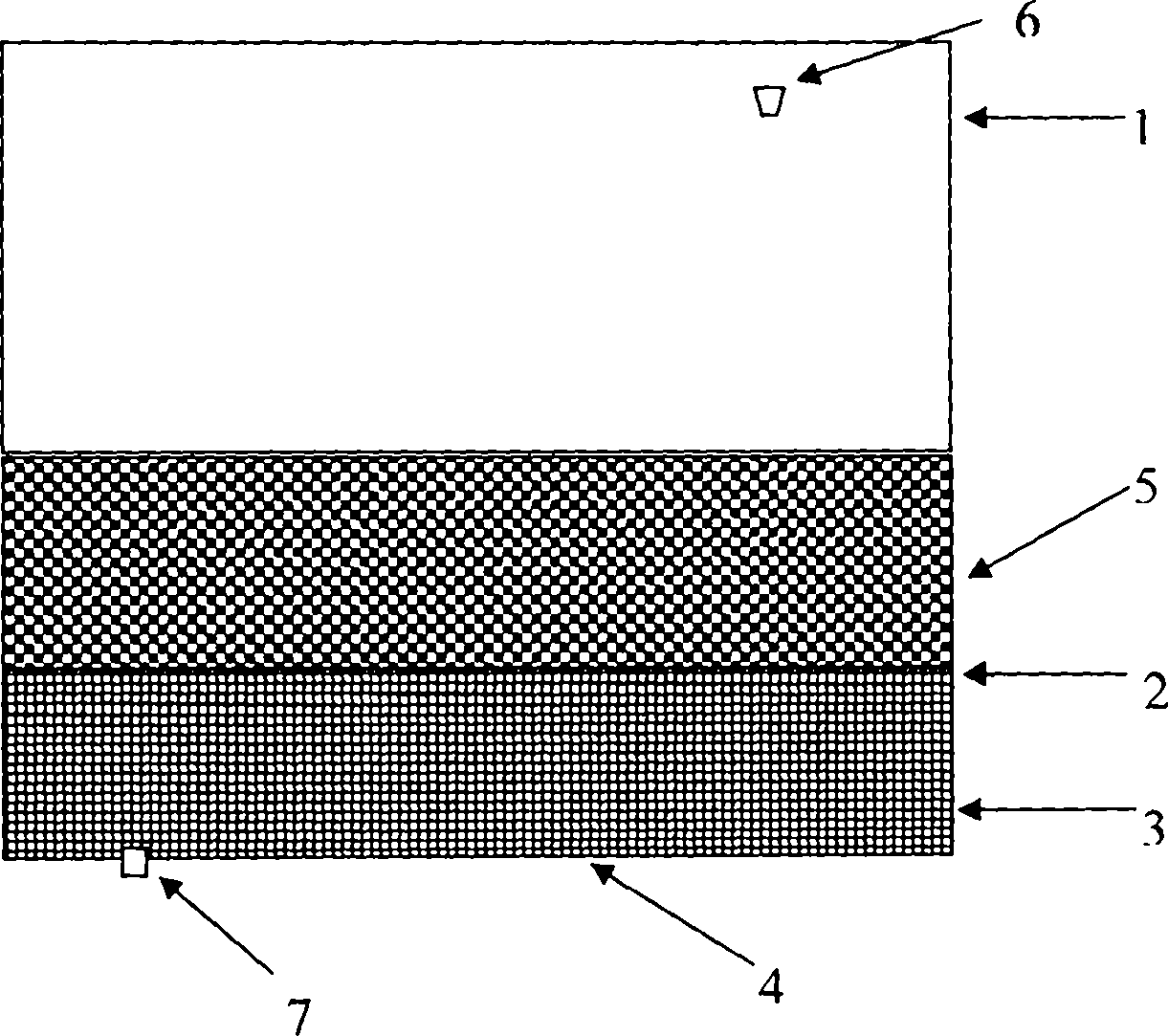

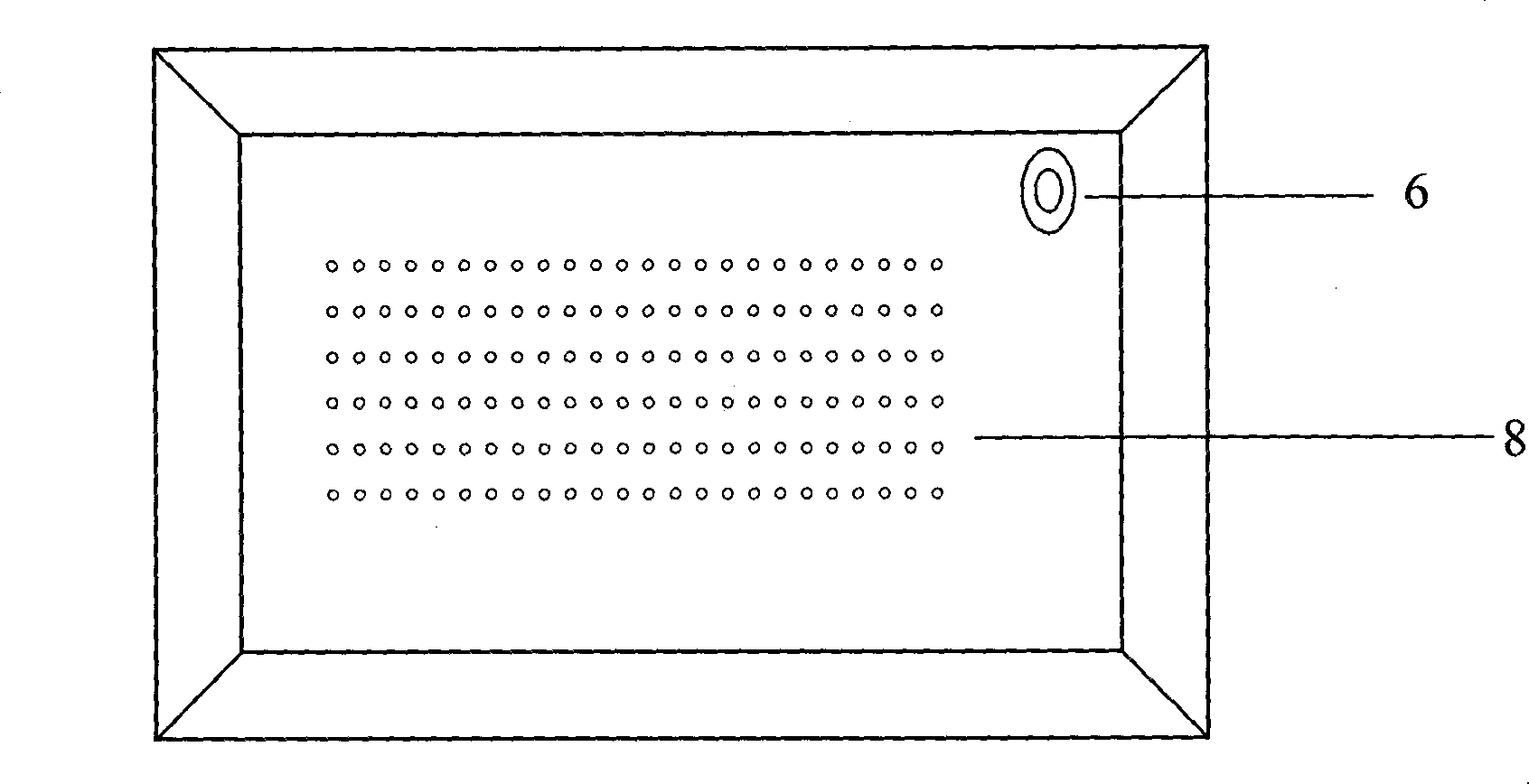

[0018] Produce the packing bag preparation of 1 kilogram of soya bean sprouts: polyethylene plastic bag specification is 400 millimeters long, 300 millimeters wide, 0.04 millimeters thick, 60 micropores of 0.2 millimeters in diameter on the upper stratum, and the water-absorbing material under the middle non-woven fabric layer weighs 100 grams ( Weigh 5.5 parts of sodium polyacrylate, 4 parts of silica gel, and 0.5 parts of sodium hypochlorite according to the ratio of 5.5:4:0.5.), put 180 grams of sterilized soybeans into heat-sealed packaging bags.

[0019] Production process of soybean sprouts: close the lower outlet of the packaging bag, add about 400 ml of clean water from the upper water inlet, the amount of water is subject to submerging the soybeans, close the water inlet and let it stand at room temperature for 24 hours, then open the lower water outlet to drain water , Put it until the water no longer flows out, connect the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com