High-precision laser photocuring 3D (three dimensional) printer

A 3D printer, high-precision technology, applied in the field of high-precision laser light-solid 3D printers, can solve the problems of ordinary enterprises, large equipment size, and easily damaged molded parts, etc., to achieve good printing effect, reduce energy consumption, and strong overload capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

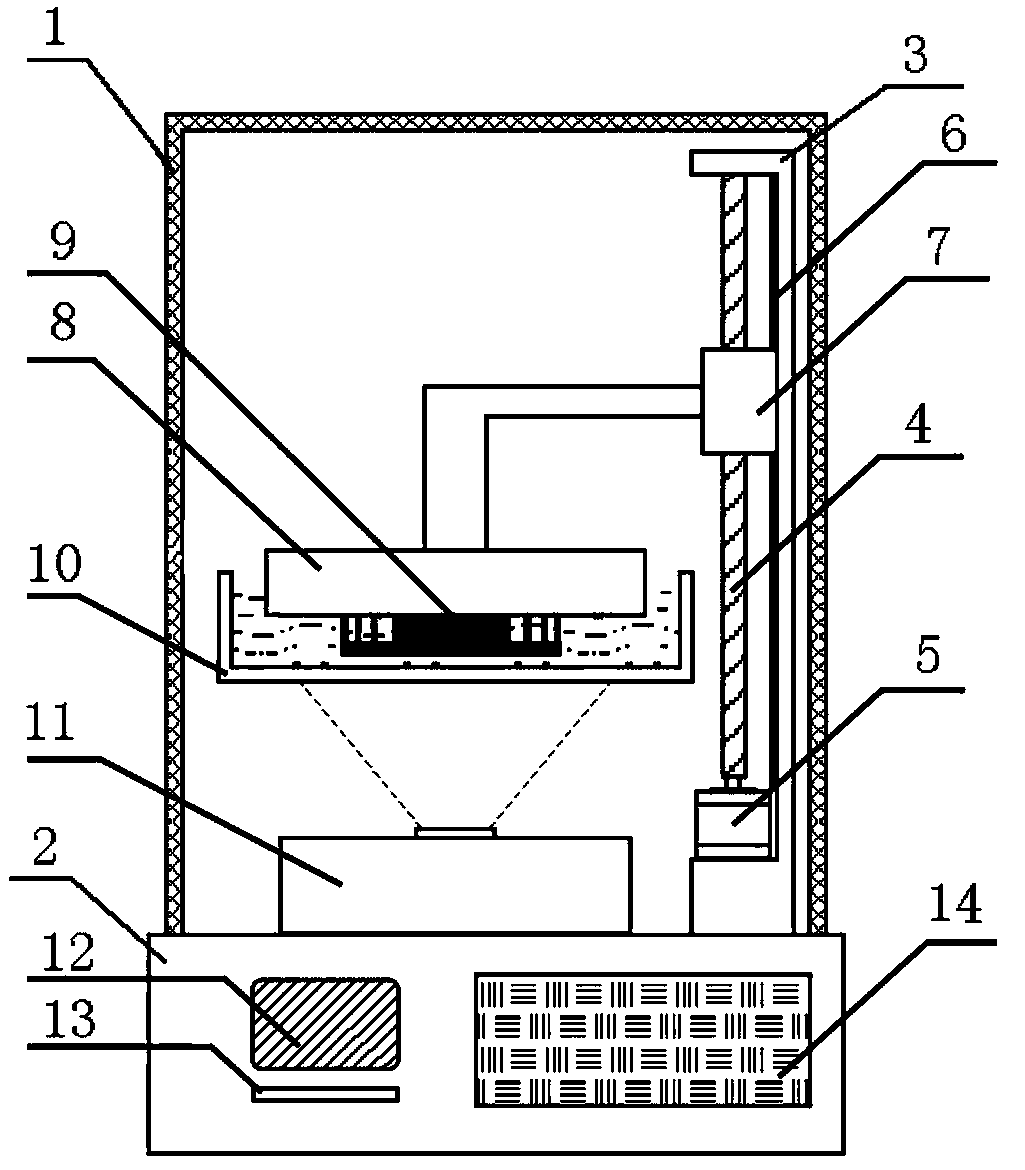

[0027] like figure 1 As shown, a high-precision laser light-solid 3D printer includes a housing 1 and a base 22, the housing 1 is connected to the upper side of the base 2, the inner side of the housing 1 is provided with a ball screw seat 3, and one side of the ball screw seat 3 is provided There is a linear guide 6, one end of the ball screw 4 is connected to the ball screw seat 3, the other end of the ball screw 4 is connected to the servo motor 5, the ball screw 4 is connected to one end of the connecting rod 7, and the other end of the connecting rod 7 is connected to the printing table 8 connection, the transparent working container 10 is fixed on the top of the base 2 through a bracket and the transparent working container 10 is directly below the printing table 8, the transparent working container 10 contains a liquid photosensitive resin and a solid photosensitive resin 9, and the solid photosensitive resin 9 is adhered to the bottom 10 of the transparent working cont...

Embodiment 2

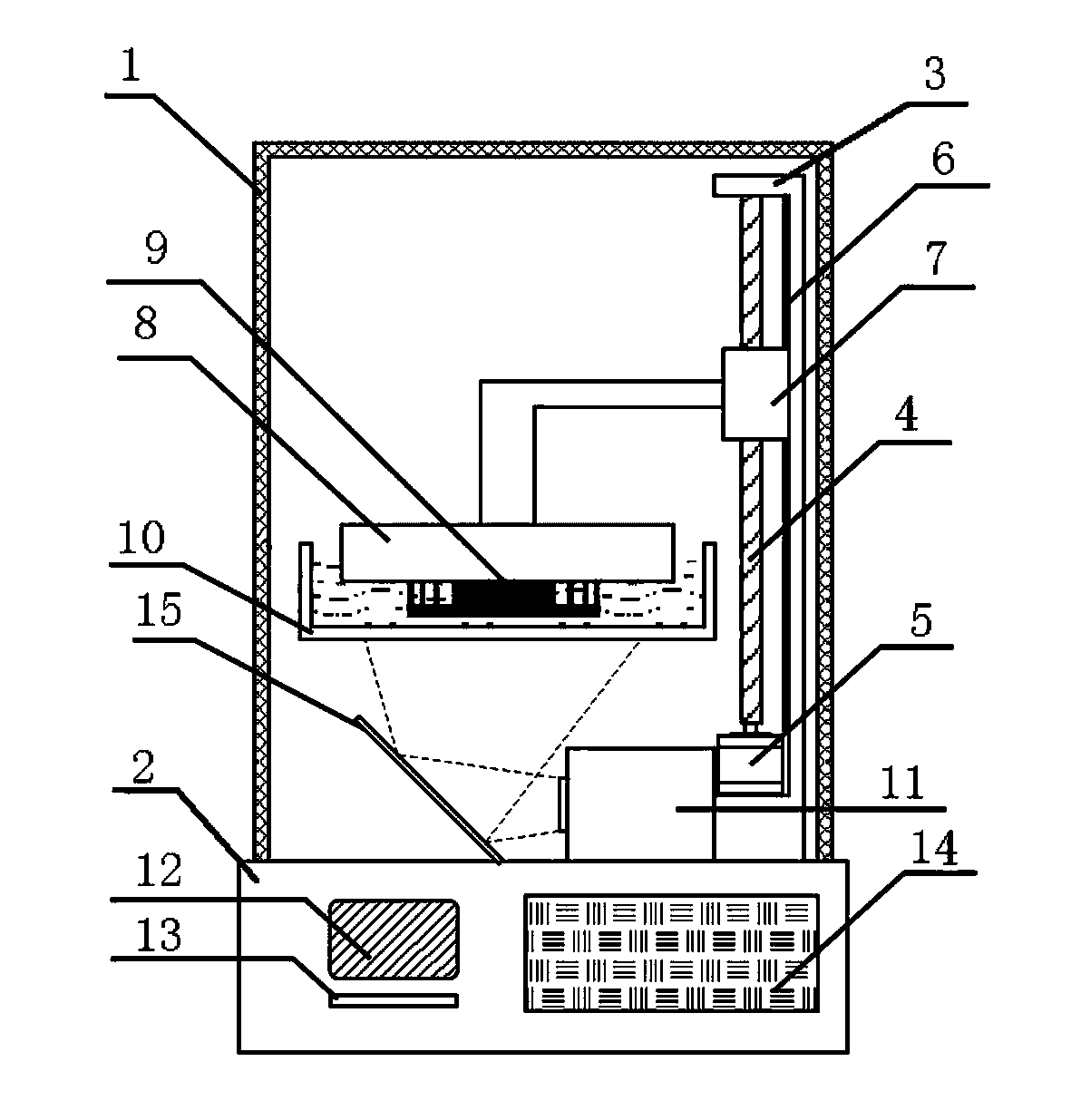

[0030] like figure 2 As shown, a high-precision laser light-solid 3D printer includes a housing 1 and a base 22, the housing 1 is connected to the upper side of the base 2, the inner side of the housing 1 is provided with a ball screw seat 3, and one side of the ball screw seat 3 is provided There is a linear guide 6, one end of the ball screw 4 is connected to the ball screw seat 3, the other end of the ball screw 4 is connected to the servo motor 5, the ball screw 4 is connected to one end of the connecting rod 7, and the other end of the connecting rod 7 is connected to the printing table 8 connection, the transparent working container 10 is fixed on the top of the base 2 through a bracket and the transparent working container 10 is directly below the printing table 8, the transparent working container 10 contains a liquid photosensitive resin and a solid photosensitive resin 9, and the solid photosensitive resin 9 is adhered to the bottom 10 of the transparent working con...

Embodiment 3

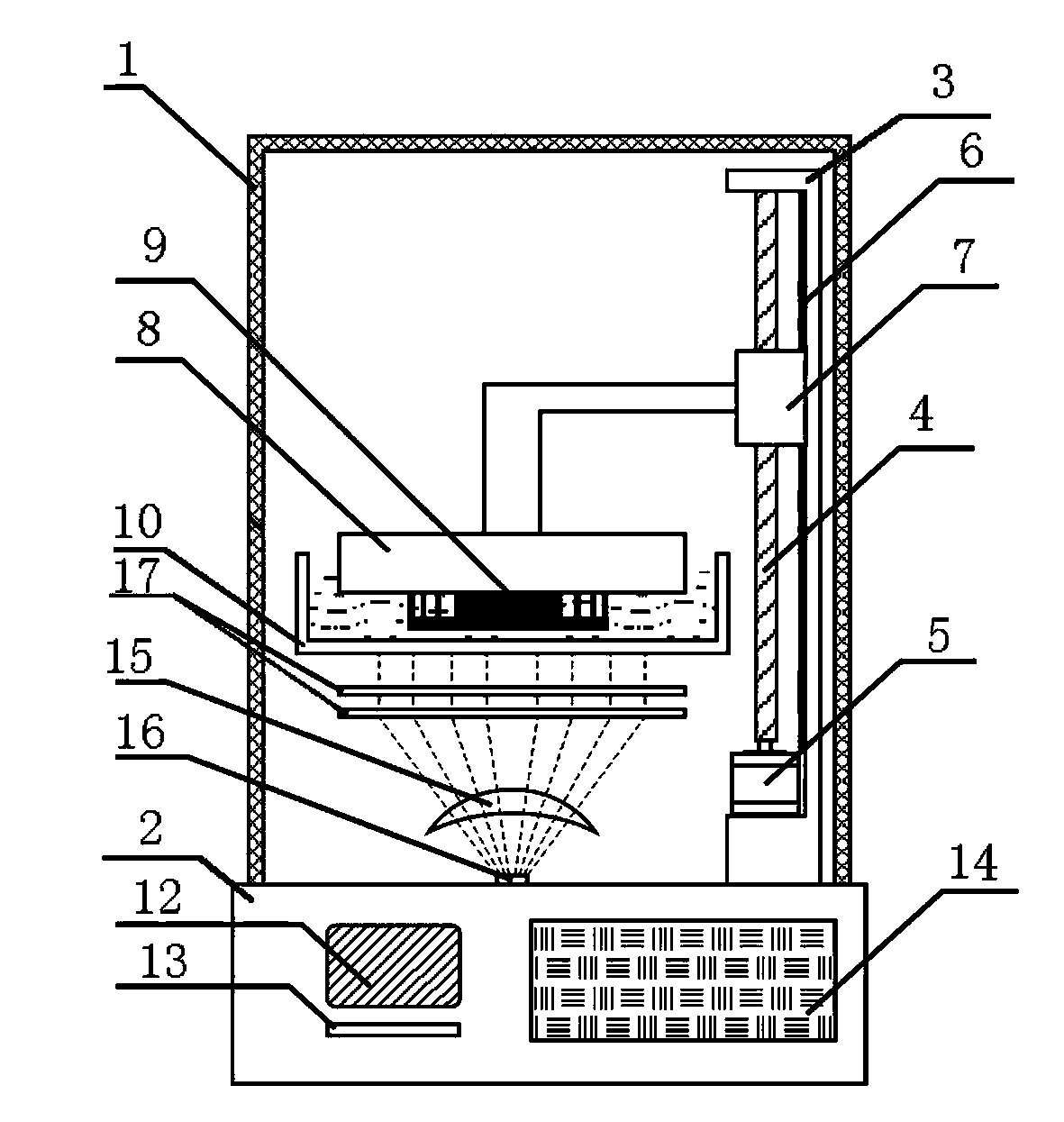

[0032] like image 3 As shown, a high-precision laser light-solid 3D printer includes a housing 1 and a base 22, the housing 1 is connected to the upper side of the base 2, the inner side of the housing 1 is provided with a ball screw seat 3, and one side of the ball screw seat 3 is provided There is a linear guide 6, one end of the ball screw 4 is connected to the ball screw seat 3, the other end of the ball screw 4 is connected to the servo motor 5, the ball screw 4 is connected to one end of the connecting rod 7, and the other end of the connecting rod 7 is connected to the printing table 8 connection, the transparent working container 10 is fixed on the top of the base 2 through a bracket and the transparent working container 10 is directly below the printing table 8, the transparent working container 10 contains a liquid photosensitive resin and a solid photosensitive resin 9, and the solid photosensitive resin 9 is adhered to the bottom 10 of the transparent working cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com