Preparation method of titanium dioxide

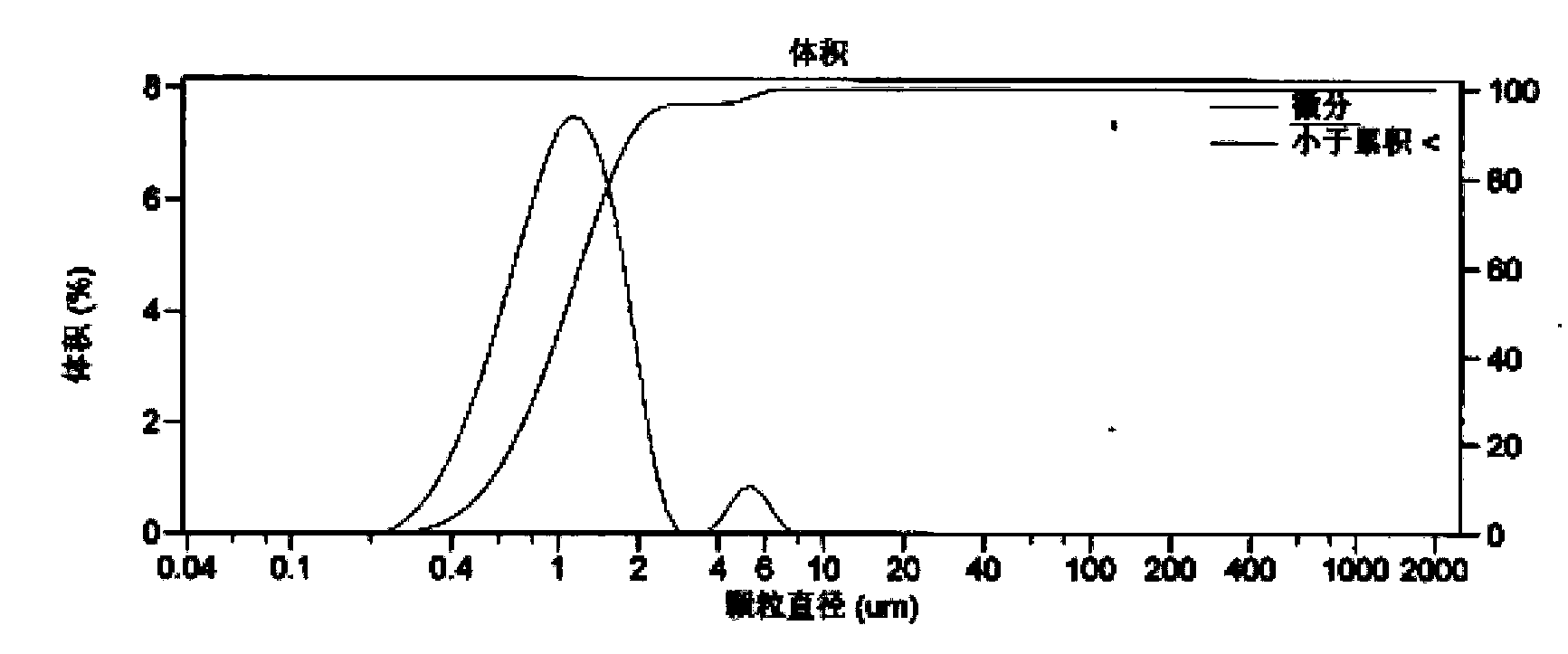

A titanium dioxide, titanium oxychloride clear liquid technology, applied in chemical instruments and methods, inorganic chemistry, titanium compounds and other directions, can solve the problems of large central particle size, serious agglomeration, large titanium particle size, etc. The effect of narrow diameter distribution and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

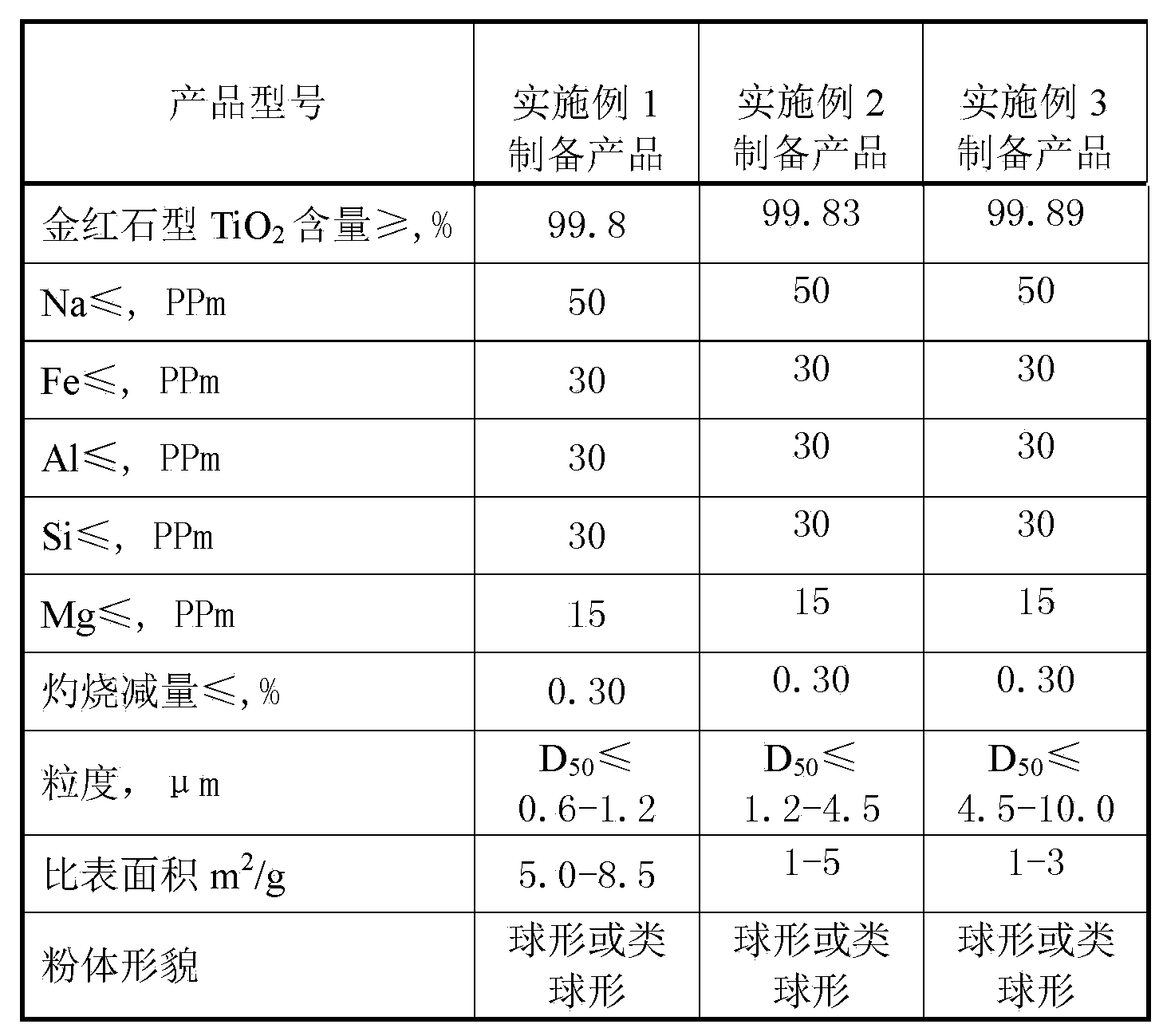

Embodiment 1

[0027] The specific steps of the method for preparing titanium dioxide of the present invention are as follows:

[0028] Step 1. The titanium tetroxide is dissolved in deionized water, and the reaction temperature is controlled at 85±3° C. to obtain a titanyl chloride solution with a titanium concentration of 3.5±0.2 mol / L. The chemical reaction equation in this step is:

[0029] TiCl 4 +H 2 O===TiOCl 2 +2HCl.

[0030] Step 2. Add ammonia water to the titanyl chloride solution obtained in step 1, the concentration of ammonia water is 9.2±0.2 mol / L, the acidity of the liquid after adding ammonia water is 4.5±0.5mol / L, and the reaction temperature is controlled at 90±3 °C to obtain a mixed buffer clear solution of hydrochloric acid, titanyl chloride and ammonium chloride. The chemical reaction equation in this step is:

[0031] NH 3 ·H 2 O+HCl===NH 4 Cl+H 2 O.

[0032] Step 3. Add a dispersant to the mixed buffer clear solution obtained in Step 2, and the reaction temperature is contro...

Embodiment 2

[0042] The specific steps of the method for preparing titanium dioxide of the present invention are as follows:

[0043] Step 1. The titanium tetroxide is dissolved in deionized water, and the reaction temperature is controlled at 85±3° C. to obtain a titanyl chloride solution with a titanium concentration of 3.5±0.2 mol / L.

[0044] Step 2. Add ammonia water to the titanyl chloride solution obtained in step 1, the concentration of ammonia water is 9.2±0.2 mol / L, the acidity of the liquid after adding ammonia water is 5.5±0.5mol / L, and the reaction temperature is controlled at 90±3 °C to obtain a mixed buffer clear solution of hydrochloric acid, titanyl chloride and ammonium chloride.

[0045] Step 3. Add a dispersant to the mixed buffer clear solution obtained in step 2, and the reaction temperature is controlled at 110±1° C., hydrolyzed at a constant temperature for 50 minutes to obtain a metatitanic acid slurry. The dispersant is gum arabic powder, and the mass of gum arabic powde...

Embodiment 3

[0049] The specific steps of the method for preparing titanium dioxide of the present invention are as follows:

[0050] Step 1. Dissolve titanium tetroxide in deionized water, and control the reaction temperature at 85±3°C to obtain a titanium dichloride clear solution with a titanium concentration of 3.5±0.2 mol / L.

[0051] Step 2. Add ammonia water to the titanyl chloride solution obtained in step 1, the concentration of ammonia water is 9.2±0.2mol / L, the acidity of the liquid after adding ammonia water is 6.5±0.5mol / L, and the reaction temperature is controlled at 90±3 °C to obtain a mixed buffer clear solution of hydrochloric acid, titanyl chloride and ammonium chloride.

[0052] Step 3. Add a dispersant to the mixed buffer clear liquid obtained in step 2, and control the reaction temperature at 110±1°C, and hydrolyze at a constant temperature for 70 minutes to obtain a metatitanic acid slurry. The dispersant is gum arabic powder, and the mass of the gum arabic powder is 2‰ of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com