Rotary-drum high-voltage pulse electric flocculation device

A high-voltage pulse and electrocoagulation technology, which is applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as large current and abnormal operation, so as to prevent passivation and save electric energy , The effect of improving the current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

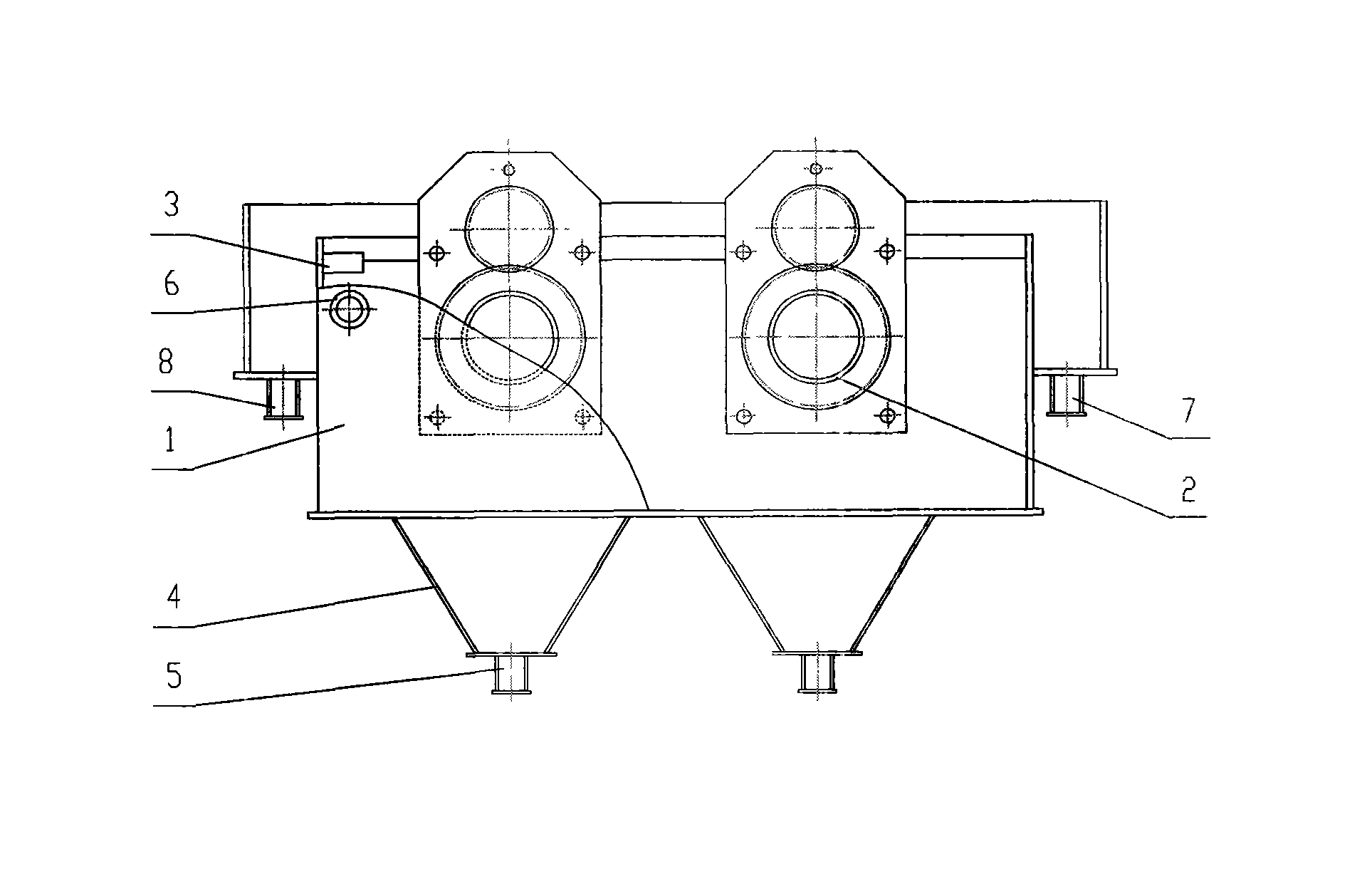

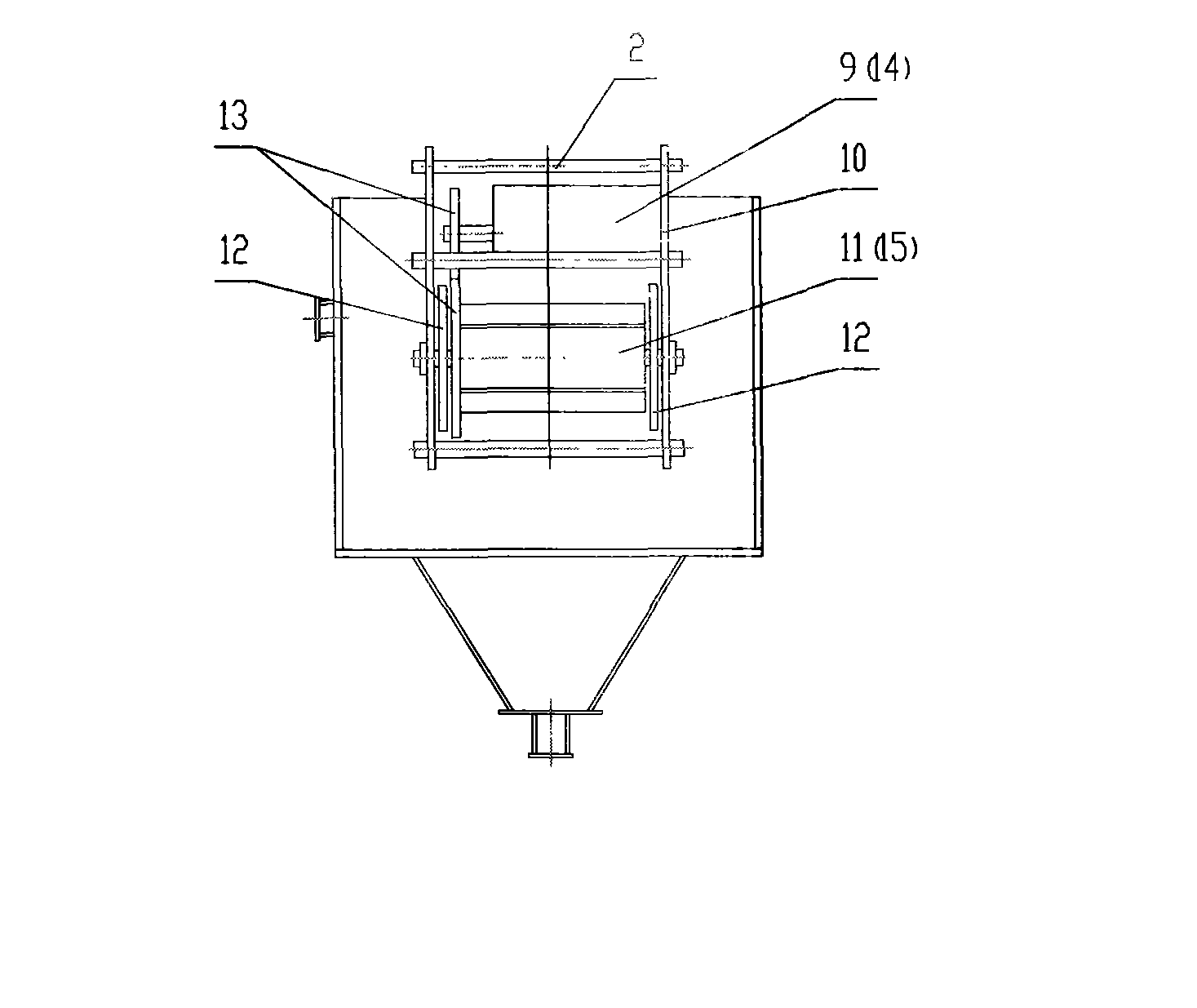

[0024] Such as figure 1 with figure 2 As shown, the electrocoagulation device according to this embodiment includes an electrolytic cell 1, a plurality of drum electrodes 2 arranged horizontally in the electrolytic cell 1, the electrolytic cell 1 has a water inlet 6 at one end, and is opposite to the water inlet 6 The other end of has drain port 7.

[0025] In this example, the electrocoagulation equipment adopts 220-380V AC input, which is converted into DC after rectification, and then uses a pulse generator to form a pulse current. The power supply requires a panel display of current and voltage, and at the same time, independent stepless adjustment of current and voltage can be realized. The current adjustment range is 0-300A, and the voltage adjustment range is 0-500V. In order to delay the plate consumption speed, the power supply has a current timing commutation function, and the commutation time is adjustable. The distance between two adjacent drum electrodes is 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com