Special compound fertilizer for grown tea as well as preparation method and applying method of tea

An application method and compound fertilizer technology, applied in the direction of fertilization methods, applications, fertilization devices, etc., can solve the problems of easily damaged roots and tea branches, and achieve the effects of saving ditching costs, improving fertilizer utilization, and avoiding mutual adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

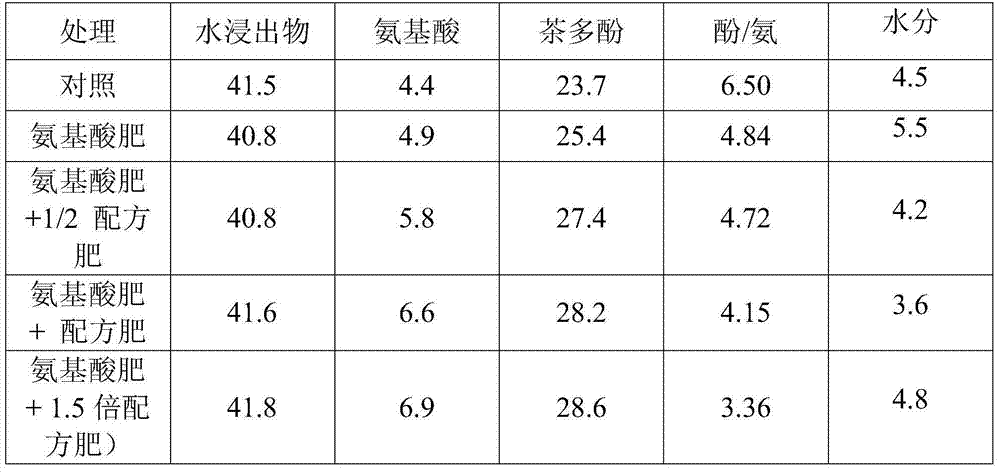

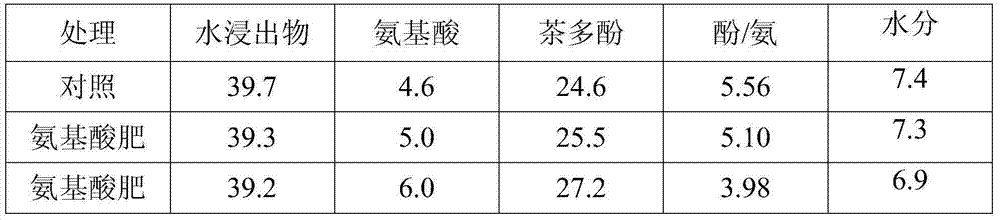

Examples

Embodiment 1

[0034] Weigh 105kg of monoammonium phosphate, 330kg of ammonium sulfate, 500kg of organic fertilizer, 80kg of potassium sulfate, 15kg of liquid ammonia and 150kg of bentonite, and grind the solid components to a particle size of 1mm with a pulverizer, and then mix for 3 minutes. After testing, in the mixed material, N, P 2 o 5 、K 2The weight ratio of O is 11:5:4, the weight content of organic matter is 35%, and the weight content of amino acid is 10%. Then granulate in the granulation equipment, dry in the drying equipment for 20 minutes under the condition of 200 ℃, then put in another drying equipment and dry for 20 minutes under the condition of 200 ℃, and then sieve to obtain Fertilizer particles I with a particle size of 2 to 4 mm. Feed the fertilizer granule I with the particle size into a drum cooler to cool to 40°C, and then sieve to obtain the fertilizer granule II with a particle size of 2-4mm, add 0.3% of the weight of the compound fertilizer for mature tea The ...

Embodiment 2

[0038] Weigh 90kg of monoammonium phosphate, 360kg of ammonium sulfate, 450kg of organic fertilizer, 60kg of potassium sulfate, 20kg of liquid ammonia and 130kg of bentonite, and grind the solid components to a particle size of 1.5mm with a pulverizer, then mix for 4 minutes. After testing, in the mixed material, N, P 2 o 5 、K 2 The weight ratio of O is 10:6:3, the weight content of organic matter is 30%, and the weight content of amino acid is 8%. Then granulate in the granulation equipment, dry in the drying equipment for 15 minutes under the condition of 200° C., then place it in another drying equipment and dry it for 25 minutes under the condition of 200° C., and then sieve to obtain Fertilizer particles I with a particle size of 2 to 4 mm. Feed the fertilizer granule I with the particle size into the drum cooler and cool it to 45°C, and then sieve to obtain the fertilizer granule II with a particle size of 2-4 mm, and add 0.2% of the weight of the compound fertilizer ...

Embodiment 3

[0042] Weigh 120kg of monoammonium phosphate, 300kg of ammonium sulfate, 550kg of organic fertilizer, 100kg of potassium sulfate, 10kg of liquid ammonia and 170kg of bentonite, and grind the solid components to a particle size of 0.5mm with a pulverizer, and then mix for 5 minutes. After testing, in the mixed material, N, P 2 o 5 、K 2 The weight ratio of O is 12:5:4, the weight content of organic matter is 38%, and the weight content of amino acid is 12%. Then granulate in the granulation equipment, dry in the drying equipment for 20 minutes under the condition of 200 ℃, then put in another drying equipment and dry for 20 minutes under the condition of 200 ℃, and then sieve to obtain Fertilizer particles I with a particle size of 2 to 4 mm. Feed the fertilizer granule I with the particle size into the drum cooler and cool it to 42°C, and then sieve to obtain the fertilizer granule II with a particle size of 2-4mm, and add 0.2% of the weight of the compound fertilizer for ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com