Preparation method for modified disperse dye dispersing agent and product

A technology of disperse dyes and diffusing agents, which is applied in the preparation of sulfonic acid, organic dyes, sulfonate, etc., to achieve the effects of reducing production costs, reducing pollution, and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

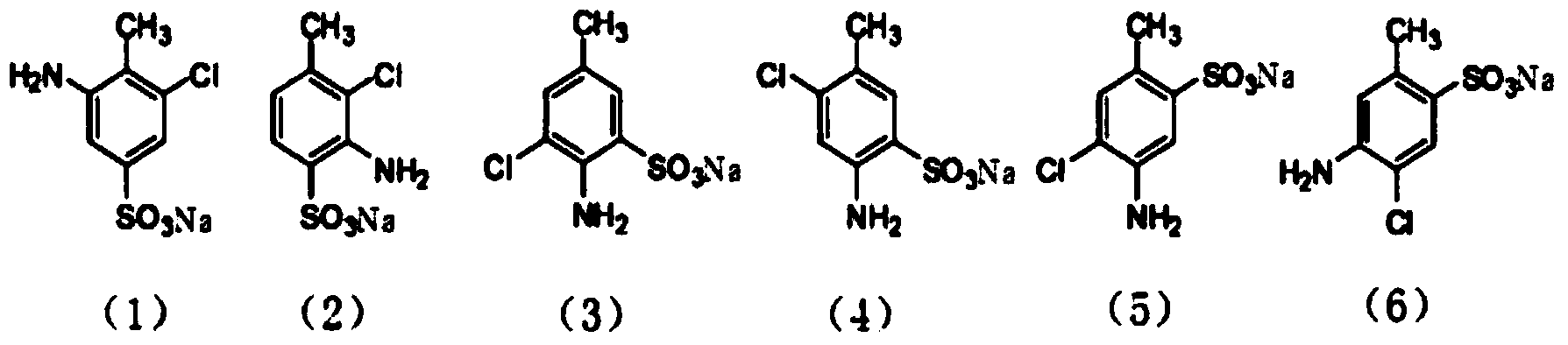

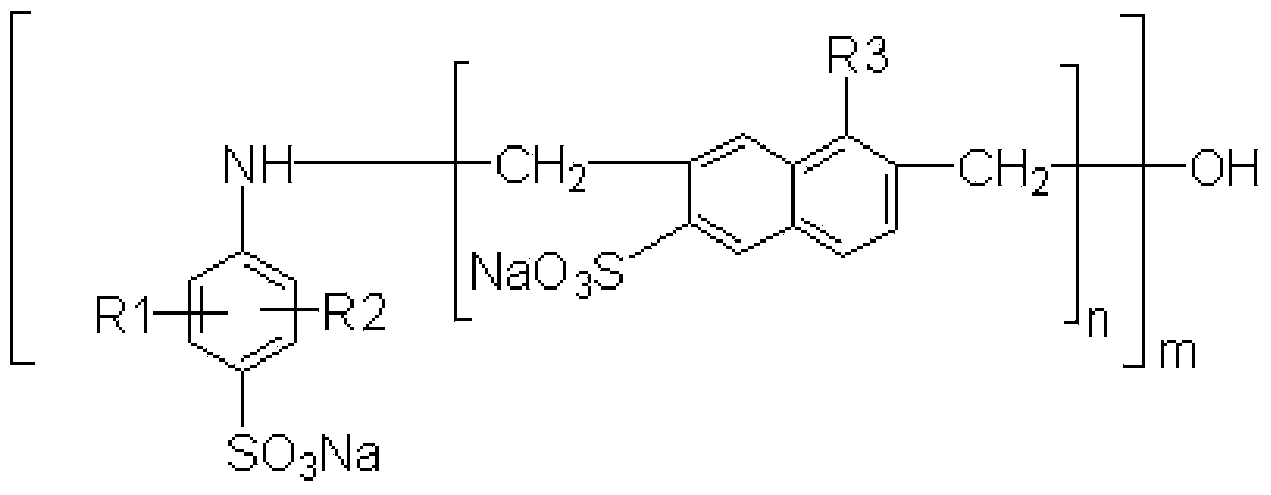

Method used

Image

Examples

Embodiment 1

[0029] 1. Production formula of modified disperse dye diffusing agent (parts by weight):

[0030]

[0031] 2. Production process of modified disperse dye diffuser:

[0032] In the reactor, add 20.0 parts of industrial methylnaphthalene (Methylnaphthalene content ≥ 60% from Zhejiang Chuanhua Energy Co., Ltd.), raise the temperature to 140°C; add 20.5 parts of 98% sulfuric acid dropwise, and control the temperature to 160°C ;Drip addition is completed, reflux reaction for 5 hours; cool down to 110°C; add 5.4 parts of water; reflux reaction for 3 hours; 16.5 parts of CLT acid wastewater containing various isomers of 23% CLT acid (selected from the CLT acid wastewater produced by Zhejiang Qinyan Chemical Co., Ltd.), the temperature is raised to 90°C; 1.5 parts of 37% formaldehyde is added dropwise, and the temperature is controlled to 90°C ; Reflux reaction for 4 hours; Obtain a solid content of 55% of the intermediate product. Neutralize the residual sulfuric acid therein, r...

Embodiment 2

[0034] 1. Production formula of modified disperse dye diffusing agent (parts by weight):

[0035]

[0036] 2. Production process of modified disperse dye diffuser:

[0037] In the reactor, add 17.0 parts of coal tar washing oil (the coal tar washing oil of Hunan Iron and Steel Co., Ltd., the content of methylnaphthalene is about 50%), and raise the temperature to 150°C; add 18.0 parts of 98% sulfuric acid dropwise, and control the temperature to 160 ℃; after the dropwise addition, reflux for 5 hours; cool down to 110°C; add 3.9 parts of water; Add 27.9 parts of CLT acid wastewater containing 23% of various isomers of CLT acid, and heat up to 90°C; add 2.4 parts of 37% formaldehyde dropwise, and control the temperature to 90°C; reflux for 4 hours; obtain a solid content of 60 % of intermediate products. Neutralize and desalt to obtain a modified disperse dye dispersant liquid product with a solid content of 40%, or a modified disperse dye dispersant powder product through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com