Silicon-plastic well lid prepared from waste polyethylene and preparation process of silicon-plastic well lid

A technology for waste polyethylene and manhole covers, applied in the field of plastic processing, can solve the problems of low mechanical properties, high price, short service life, etc., and achieve the effects of excellent bearing capacity, low cost and strong weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

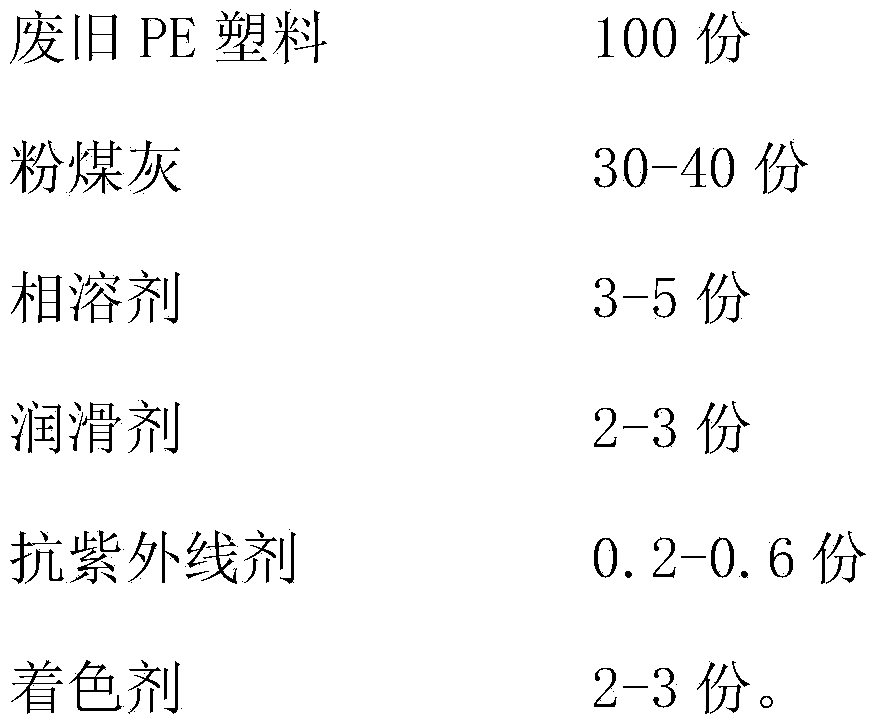

[0015] 1. Raw material composition:

[0016]

[0017]

[0018] The phase solvent is maleic anhydride grafted phase solvent, the lubricant is polyethylene wax, and the colorant is iron oxide red.

[0019] Among them, the waste PE plastic is made from the original cable sheath of waste and old cables after being crushed to particles with a particle size of 3-5mm. The crushed cable sheath particles are rinsed with water, soaked, and layered. The obtained upper liquid contains polyvinyl chloride ( PE) particle solution, take the upper solution for centrifugation (the speed of the centrifuge is 1000-1500r / min), filter, and the obtained solid is naturally dried to obtain waste polyethylene plastic.

[0020] 2. Preparation method:

[0021] Mix the dried components at high speed to 170-200°C, quickly take them out, put them into the mold under the condition of at least 20MPa, keep the pressure for 20-90min, die-cast, and after cooling, trim the edges.

Embodiment 2

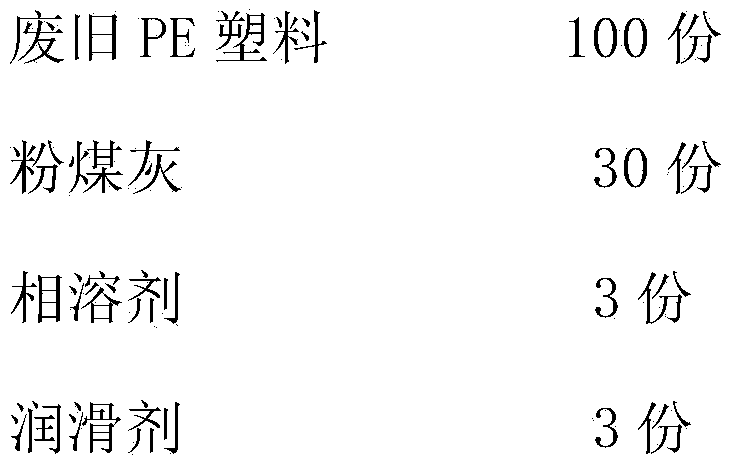

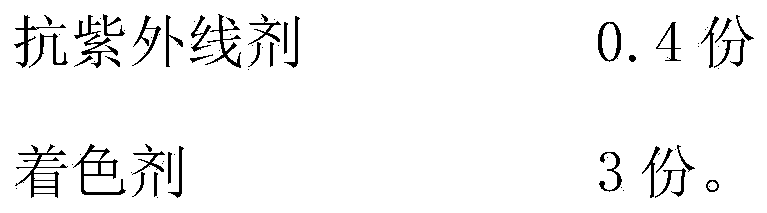

[0023] 1. Raw material composition:

[0024]

[0025] The phase solvent is chlorinated polyethylene phase solvent, the lubricant is polyethylene wax, and the coloring agent is iron oxide red.

[0026] Among them, the waste PE plastic is made from the original cable sheath of waste and old cables after being crushed to particles with a particle size of 3-5mm. The crushed cable sheath particles are rinsed with water, soaked, and layered. The obtained upper liquid contains polyvinyl chloride ( PE) particle solution, take the upper solution for centrifugation (the speed of the centrifuge is 1000-1500r / min), filter, and the obtained solid is naturally dried to obtain waste polyethylene plastic.

[0027] 2. Preparation method:

[0028] Mix the dried components at high speed to 170-200°C, quickly take them out, put them into the mold under the condition of at least 20MPa, keep the pressure for 20-90min, die-cast, and after cooling, trim the edges.

Embodiment 3

[0030] 1. Raw material composition:

[0031]

[0032] The phase solvent is an acrylate phase solvent, the lubricant is polyethylene wax, and the colorant is iron oxide yellow.

[0033] Among them, the waste PE plastic is made from the original cable sheath of waste and old cables after being crushed to particles with a particle size of 3-5mm. The crushed cable sheath particles are rinsed with water, soaked, and layered. The obtained upper liquid contains polyvinyl chloride ( PE) particle solution, take the upper solution for centrifugation (the speed of the centrifuge is 1000-1500r / min), filter, and the obtained solid is naturally dried to obtain waste polyethylene plastic.

[0034] 2. Preparation method:

[0035] Mix the dried components at high speed to 170-200°C, quickly take them out, put them into the mold under the condition of at least 20MPa, keep the pressure for 20-90min, die-cast, and after cooling, trim the edges.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com