Oceanic heavy corrosion resistant self-stratifying coating

A heavy-duty anti-corrosion and self-layering technology, which is applied in anti-corrosion coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor weather resistance, high cost, and poor interlayer adhesion, so as to reduce the process and improve production Effect of efficiency, strong interlayer adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

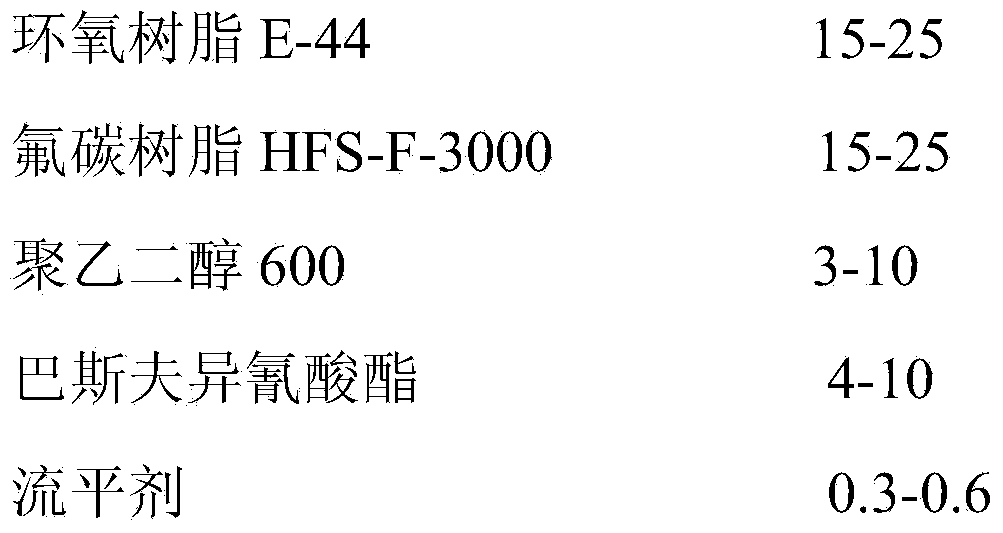

[0035] The mass dosage of each component is as follows (Kg):

[0036]

[0037] The preparation method is: weigh according to the above formula, add epoxy resin E-44, fluorocarbon resin HFS-F-3000 and curing agent HB175 into the dispersion tank, add dispersant PEG600, defoamer, fluid under stirring Leveling agent, solvent DMAC, solvent xylene, pigment ferric oxide, high-speed dispersion for 30 minutes.

[0038] The performance indicators of the prepared coating are shown in Table 2 after testing:

[0039] Table II

[0040] project

Embodiment 2

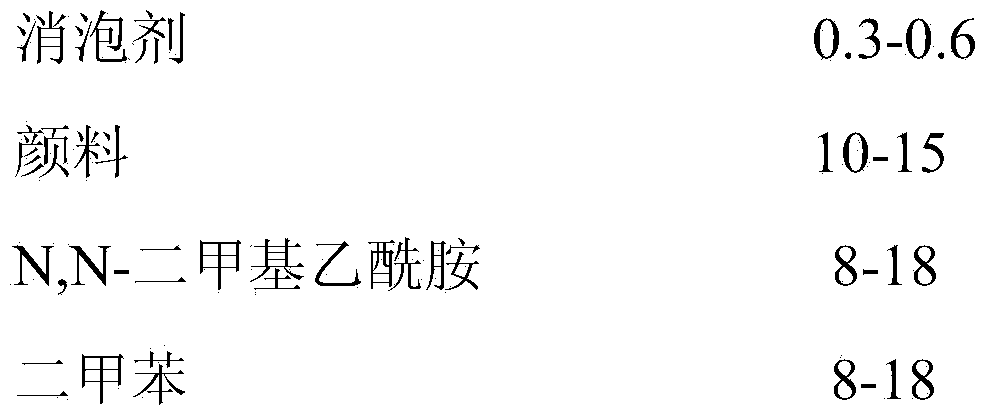

[0042] The mass dosage of each component is as follows (Kg):

[0043]

[0044] The preparation method of embodiment two is identical with embodiment one, and the various performance indexes of the coating that prepares are tested are table three:

[0045] Table three

[0046] project

Embodiment 3

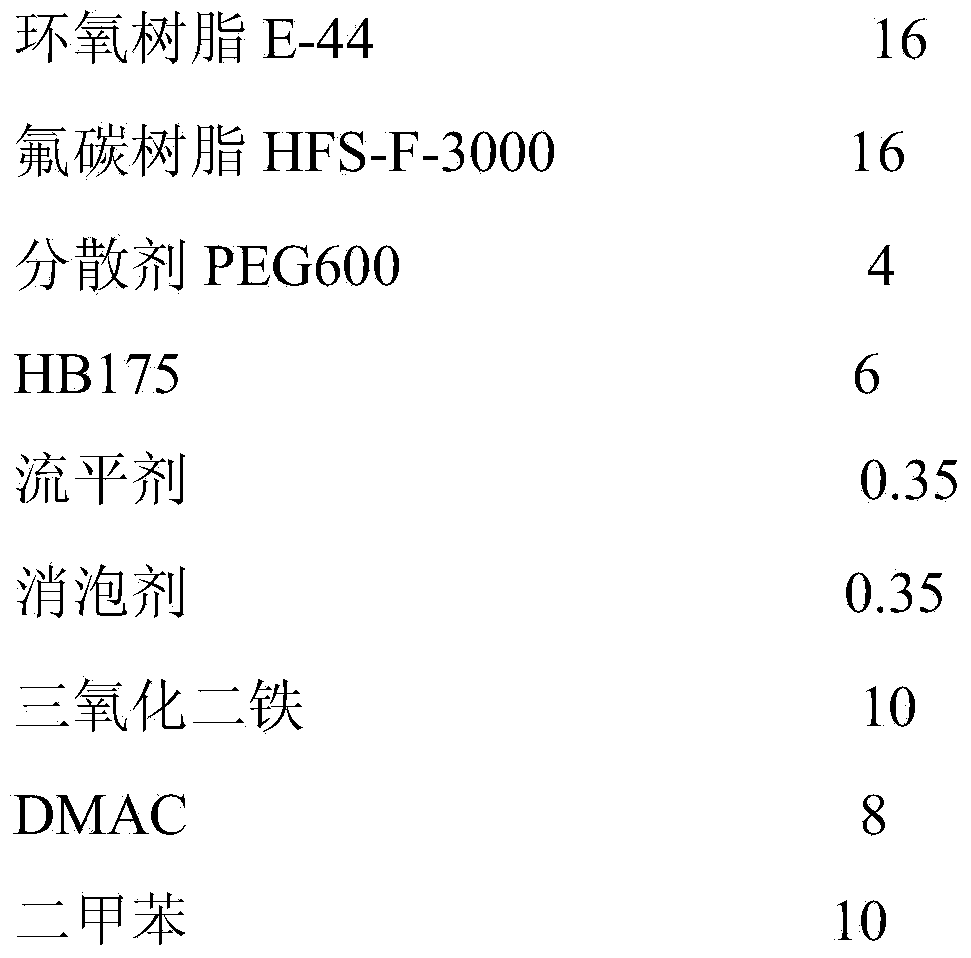

[0048] The mass dosage of each component is as follows (Kg):

[0049]

[0050] The preparation method of embodiment three is identical with embodiment one, and the various performance indexes of the coating that prepares are tested are table four:

[0051] Table four

[0052]

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com