Wet etching device

A wet etching and equipment technology, applied in the field of wet etching equipment, can solve problems such as transitional etching, product lamination, liquid level sensor false alarms, etc., to achieve the effect of reducing mura, preventing problems from occurring, and reducing the burden on personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The technical content of the present invention is further described below in conjunction with accompanying drawing and embodiment:

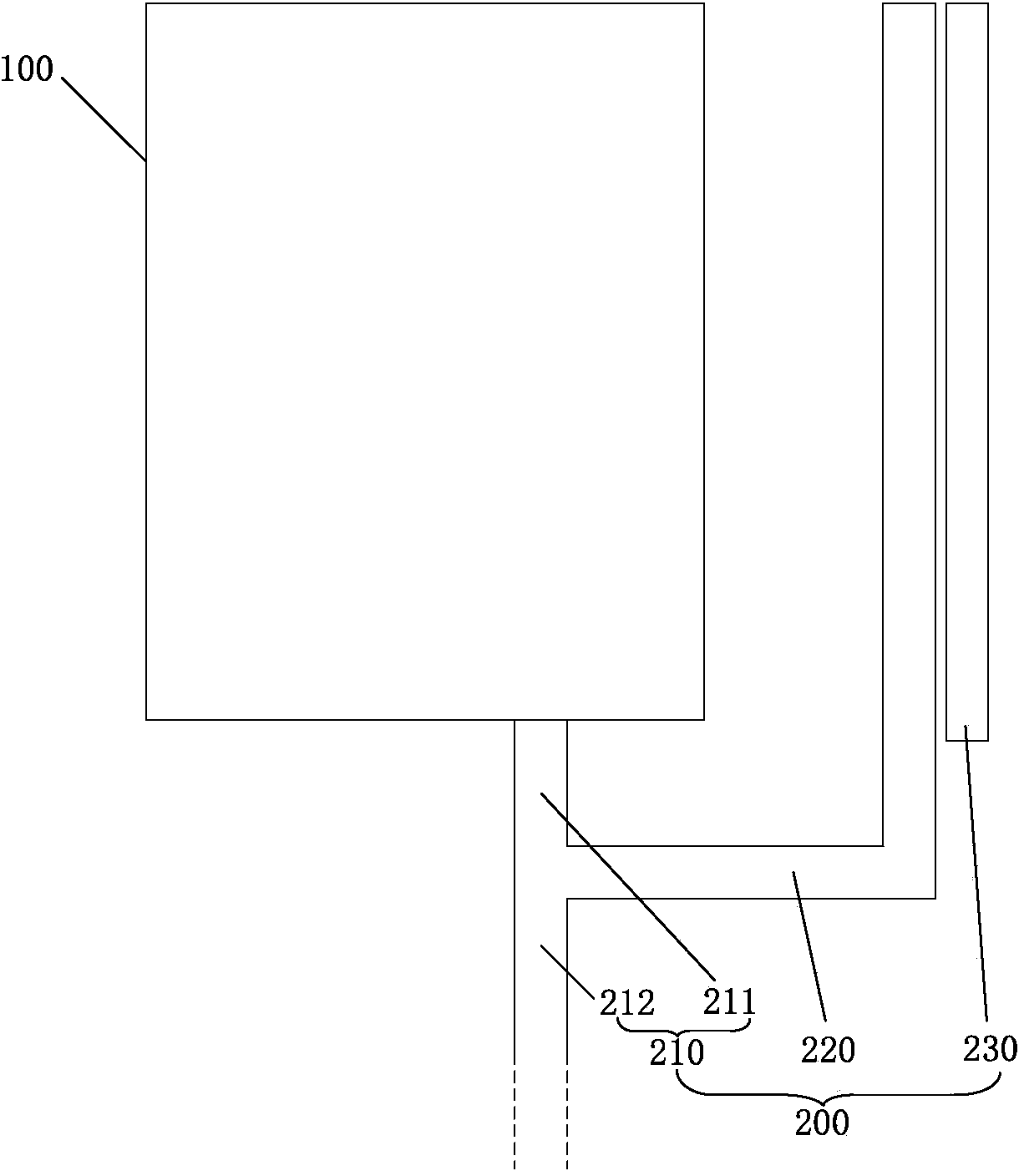

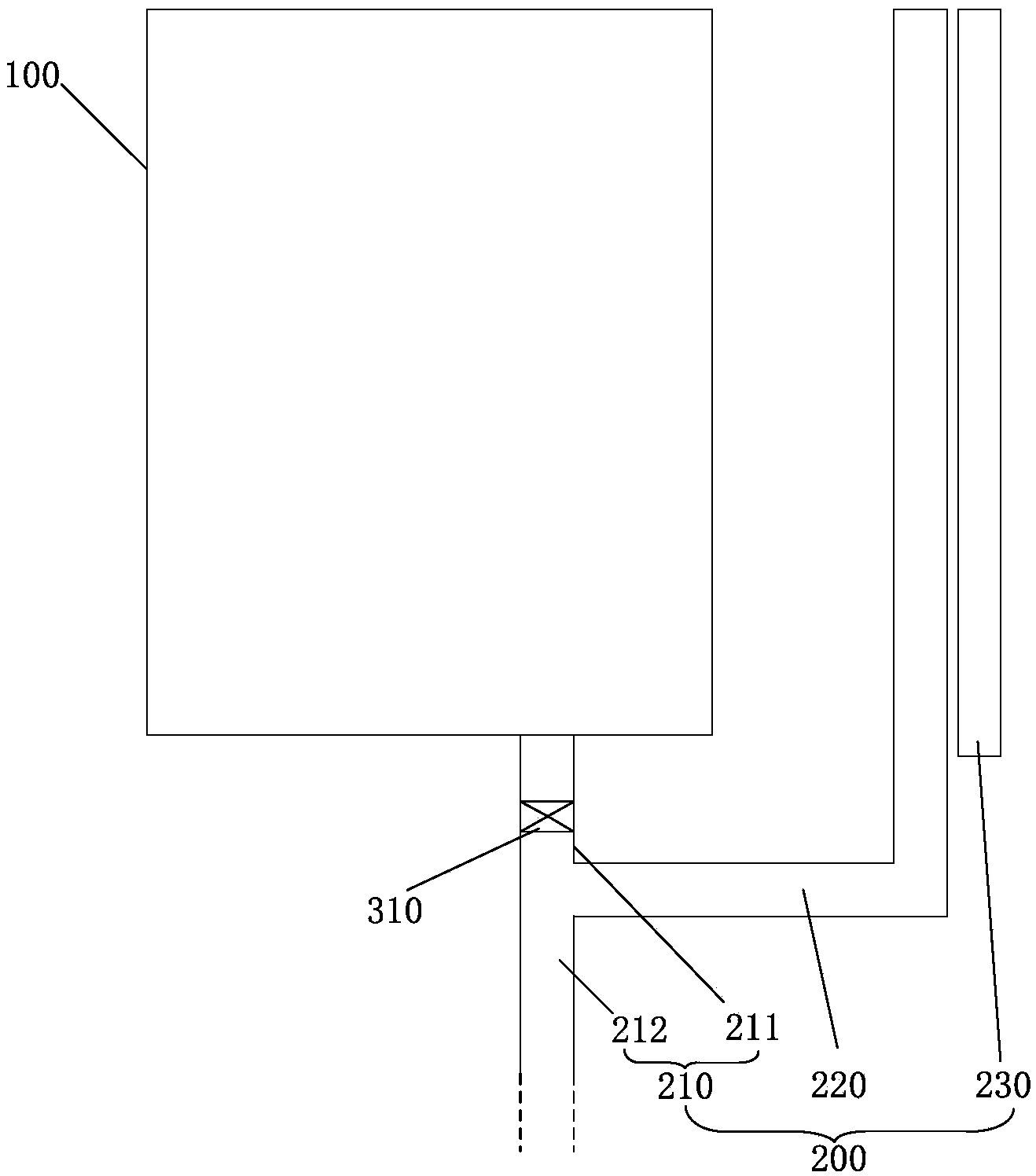

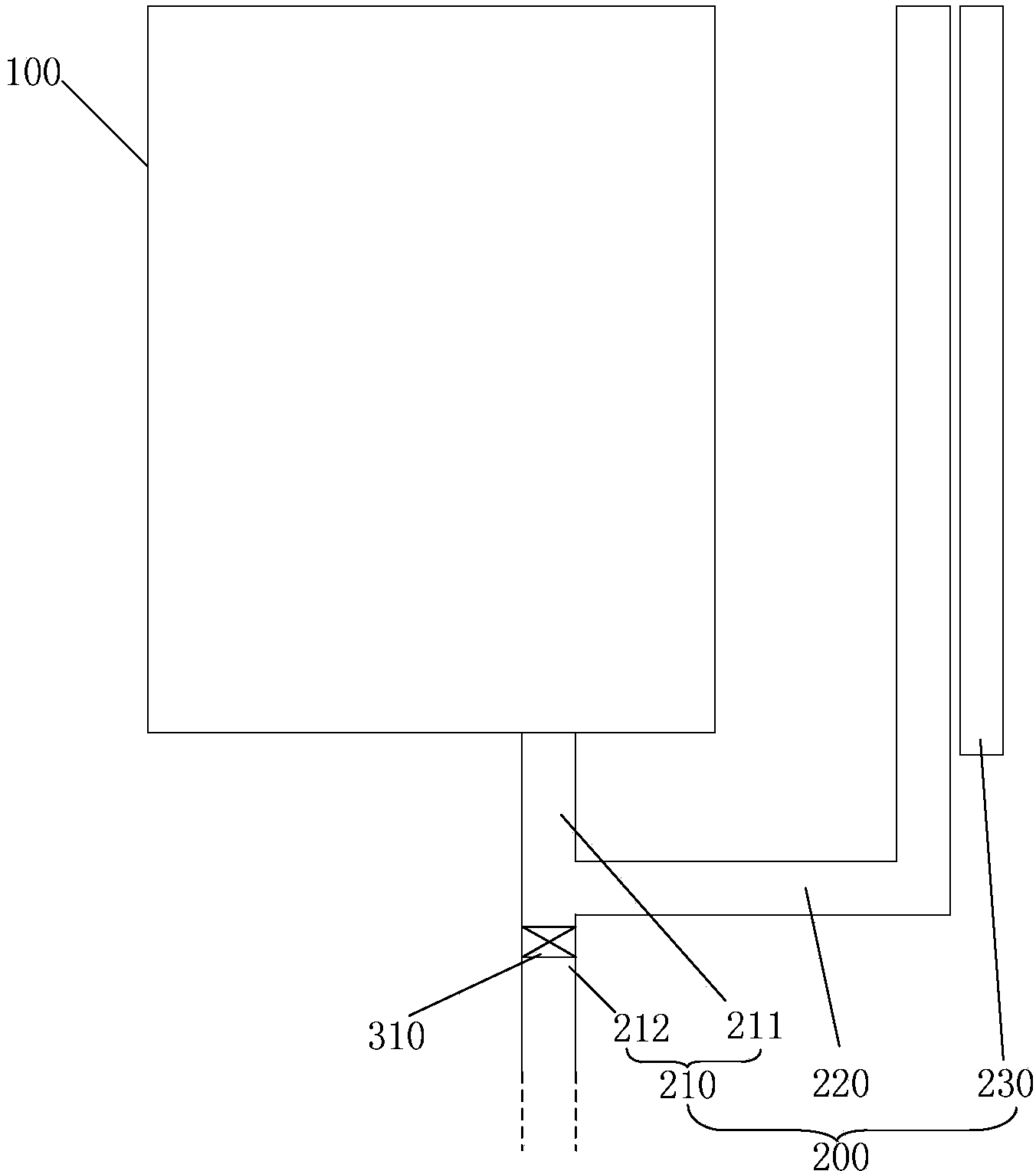

[0055] figure 2 A schematic structural diagram of a wet etching device according to a first embodiment of the present invention is shown. Specifically, specifically, such as figure 2 shown, with figure 1 Similar to the prior art shown, the wet etching equipment includes a machine 100 and a connecting pipeline 200 . Wherein, the machine 100 is filled with a chemical liquid, and the semiconductor device placed in the machine 100 is etched. The connecting pipeline 200 is connected to the bottom of the machine 100 and transmits the liquid medicine to the machine 100 . More specifically, the connecting pipeline 200 includes: a liquid-taking pipeline 210 , a liquid level tank 220 and a liquid level sensor 230 . The liquid-taking pipeline 210 communicates with the bottom of the machine 100 . The liquid level tank 220 is connected to the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com