High-impermeable anti-floating pile raft structure and construction method

A technology of anti-floating piles and rafts, which is applied in basic structure engineering, construction, etc., can solve the problems of difficult design and construction, waste of building materials, low material utilization rate, etc., achieve good technical and economic benefits and environmental benefits, and improve construction Efficiency and utilization improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In this embodiment, the design and construction technical requirements of the foundation pit surrounding protection piles and the concrete wall of the basement side wall, the construction technical requirements of steel bar binding and steel plate welding, the construction technical requirements of the reinforced layer and the laying of the horizontal water-resisting layer, and the coordination of cement and soil Compared with the technical requirements of construction, etc., it will not be repeated in this embodiment, and the implementation mode of the structure related to the present invention will be focused on.

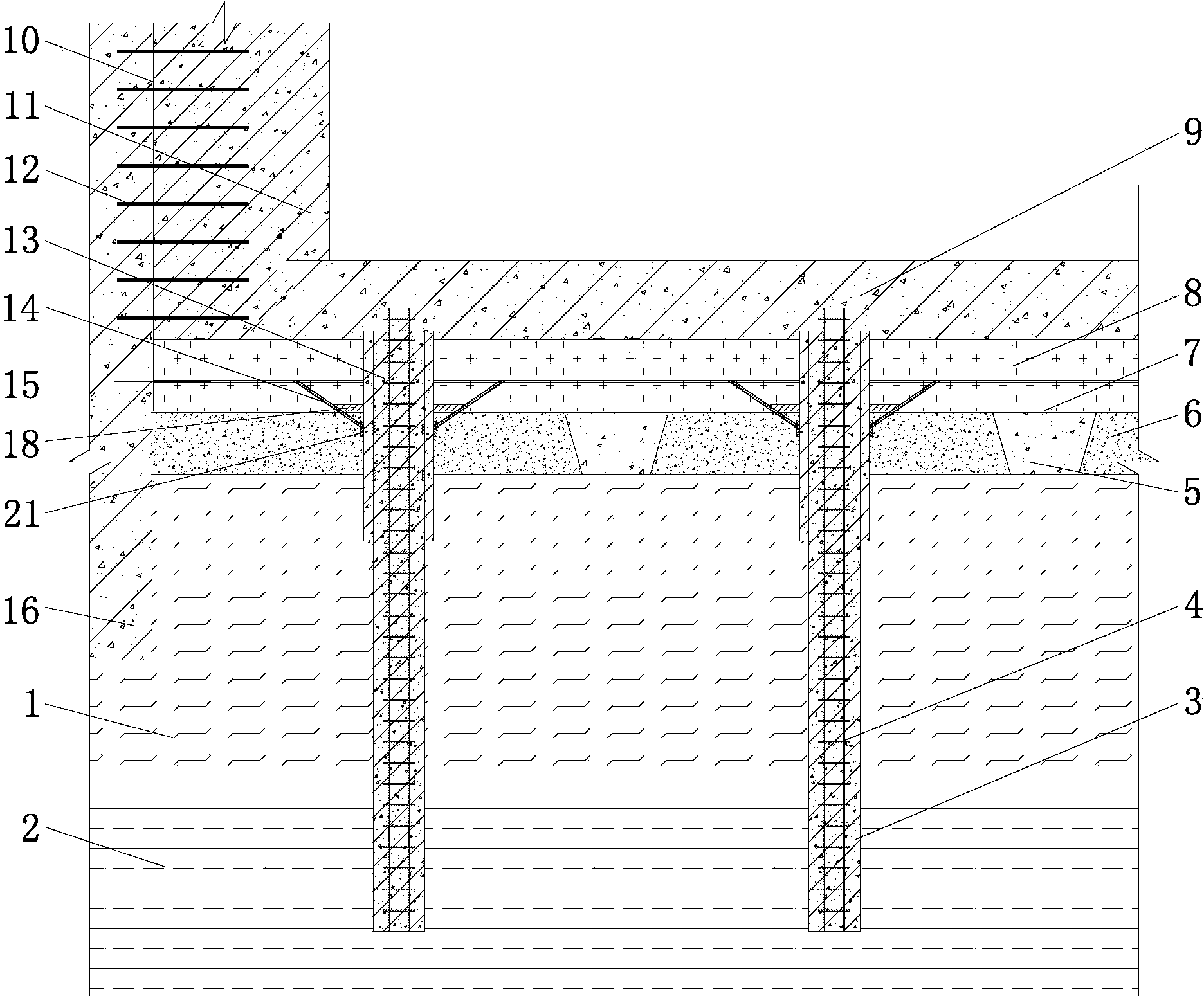

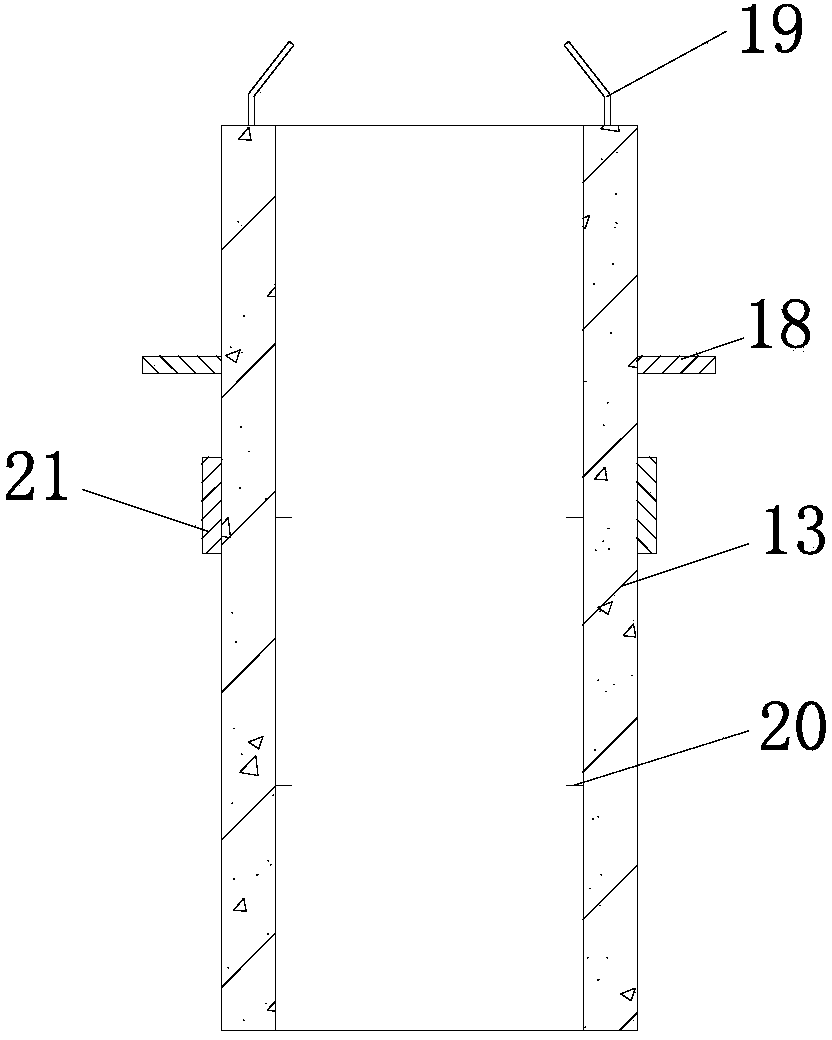

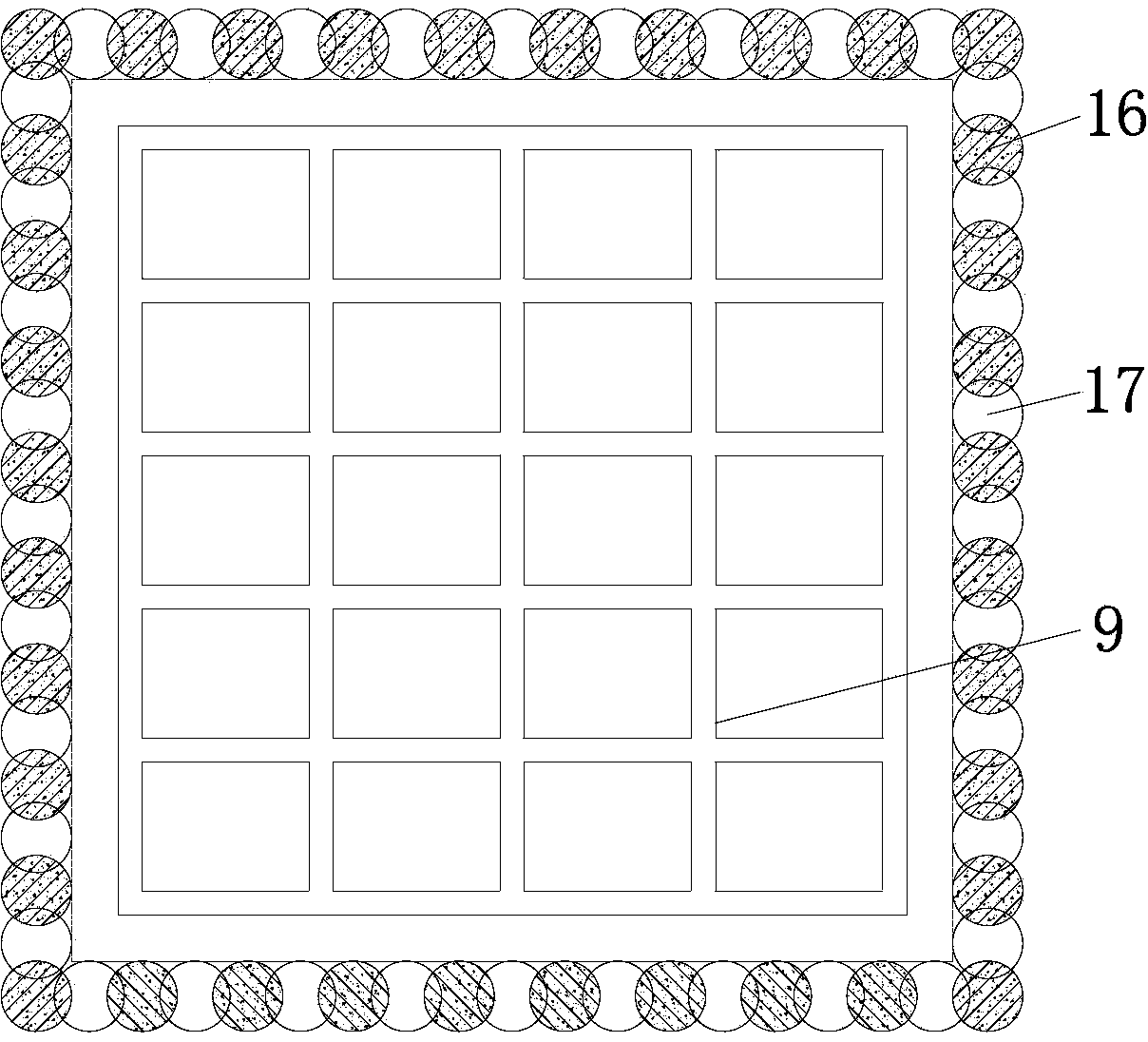

[0044] figure 1 It is a schematic diagram of the structure of a high anti-seepage and anti-floating pile raft according to the present invention, figure 2 It is a schematic diagram of the prestressed hollow pipe section of the present invention, image 3 It is a schematic diagram of the foundation pit structure of the present invention. refer to figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com