In-doped zinc sulfide thin film and preparation method and application thereof

A technology of thin film and doping amount, which can be used in final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc. The effect of reducing the resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Get 15ml of zinc acetate with a concentration of 0.4mol / L, and 15ml of sodium citrate with a concentration of 0.1mol / L, according to the doping amount of 0 at.%, 0.5 at.%, 1 at.%, 2 at.%, 3 at.%, 4 at.% indium sulfate as doping source. Add 87.5ml of deionized water and mix well. Acetic acid was added dropwise to the solution to adjust the pH of the solution to 4.0.

[0018] Place the solution in a water bath for heating. After the temperature of the solution reached 85° C., 15 ml of thioacetamide with a concentration of 0.4 mol / L was added to the solution. Starting from the time of adding thioacetamide, react at a water bath temperature of 85° C. for 1.5 h.

[0019] The deposited In-doped ZnS film was deposited on N 2 Annealing treatment was carried out in the atmosphere, the temperature of annealing treatment was 350°C, the time of annealing treatment was 1.5 h, and cooled to room temperature.

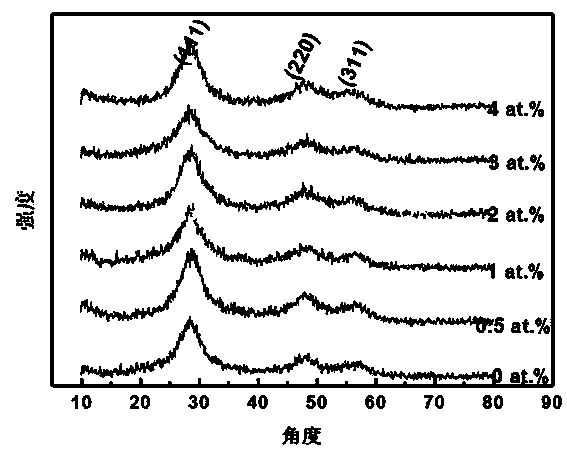

[0020] Phase analysis of In-doped ZnS thin films.

[0021] figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com