Electroluminescent device with high light emitting efficiency

An electroluminescent device and electroluminescent layer technology, which can be applied to electro-solid devices, electrical components, semiconductor devices, etc., can solve the problems of low luminous efficiency and cumbersome preparation process, and achieve a simple preparation process and easy large-scale mass production. , the effect of improving light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

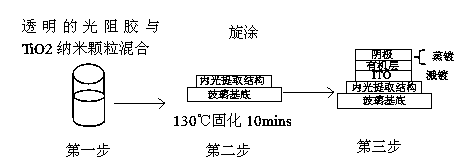

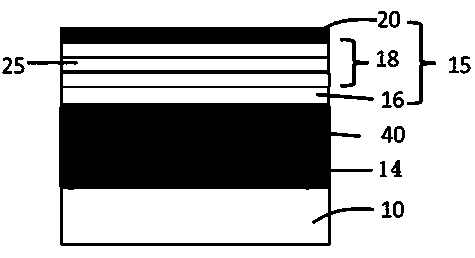

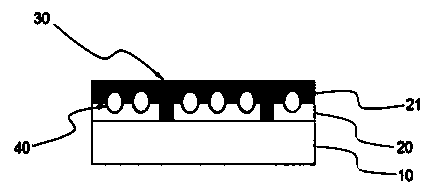

[0083] Such as Figure 4 As shown, the high-efficiency luminescent electroluminescent device of the present embodiment includes: a transparent substrate 1, a light scattering layer 2 on the transparent substrate 1, a surface smooth layer 3 on the light scattering layer 2, and a surface smooth layer 3 on the surface smooth layer 3. The electroluminescent layer; the light scattering layer 2 and the smooth surface layer 3 constitute the light extraction layer,

[0084] The light-scattering layer 2 includes egg-shaped light-scattering particles and a binder;

[0085] The surface smooth layer 3 includes inorganic nanoparticles and organic matrix with high refractive index;

[0086] The electroluminescent layer includes a transparent electrode layer 4 on the smooth surface layer,

[0087] An anti-short circuit layer 5 on the transparent electrode layer 4, an OLED light-emitting unit layer 6 with at least one light-emitting layer and a reflective electrode layer 7,

[0088] The su...

Embodiment 2

[0098] Example 2 Preparation of light scattering layer

[0099] 1) Preparation of egg-shaped light-scattering particles

[0100] Take 20g of titanium dioxide (DuPont R series), add 80g of solvent toluene and 1g of dispersant (Lubrizol Solsperse series), put 100g of grinding medium, put it in a ball mill, set the speed at 100rpm, and take a sample to analyze the kinetics after 5h Light scattering particle size. As shown in Figure 5, the effective particle size is 337.1nm.

[0101] 2) Preparation of light scattering layer

[0102] Take 10g of TiO prepared in the previous step 2Mix the suspension with 0.20 g of UV glue (Gulibao UV glue), take about 1mL of the mixture and add it dropwise on a 63.5*63.5mm glass substrate, and spin-coat at 1000 rpm to obtain a light-scattering layer. After UV curing for 15s, heat at 90 °C Baking for 15 minutes, the film thickness is 500-600nm.

Embodiment 3

[0103] Example 3 Preparation of light scattering layer

[0104] 1) Preparation of egg-shaped light-scattering particles

[0105] Mix 74.2g of dispersant (Lubrizol Solsperse series) and 2L of toluene in the grinding bucket evenly, add 742g of titanium dioxide (DuPont R series), stir for 10mins, start high-speed grinding, and take a sample to test the dynamic light scattering particle size after 1h. Such as Figure 6 As shown, the effective particle size is 284.2nm.

[0106] 2) Preparation of light scattering layer

[0107] Get 6.7g of the TiO prepared in the previous step 2 Suspension, after mixing 0.2g UV glue (Gulibao UV glue) and 3.1g toluene evenly, take 1ml of the mixture and add it dropwise on a 63.5*63.5mm glass substrate, spin coating at 1000 rpm to obtain a light scattering layer, and UV curing After 15 s, bake at 90°C for 15 min, and the film thickness is 400-500nm.

[0108] The surface morphology of the light scattering layer was analyzed. The surface roughnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com