Special compound feed for capons and preparation method thereof

A compound feed and capon technology, applied in animal feed, animal feed, application, etc., can solve problems such as poor resistance and high mortality, and achieve the effects of balanced nutrition, simple preparation, and optimal production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A special compound feed for capons is prepared, comprising the following process steps:

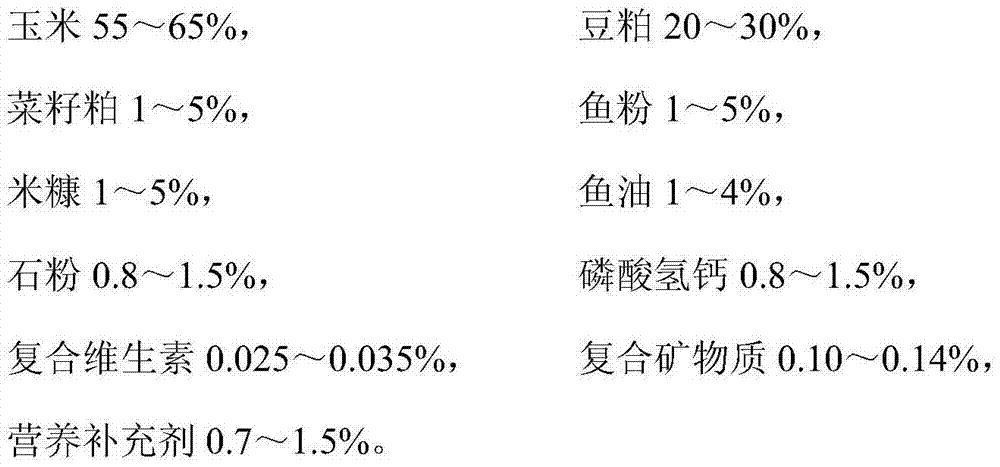

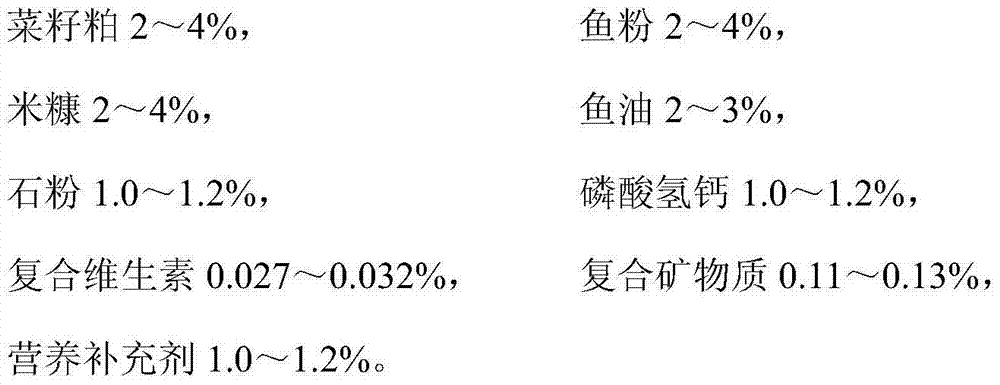

[0033] 1. Weigh the component raw materials in the following weight percentages:

[0034] Corn 58%, soybean meal 22%, rapeseed meal 5%, fish meal 4%, rice bran 5%, fish oil 2%, stone powder 1.2%, calcium hydrogen phosphate 1.3%, multivitamin 0.034%, multimineral 0.11%, nutritional supplement 1.356%.

[0035] The nutritional supplement is composed of the following components in parts by weight: 28 lysine, 18 methionine, 6 threonine, 8 choline, 23 sodium bicarbonate, 14 salt, and 3 enzyme preparations.

[0036] 2. Mix the raw materials of the above components at room temperature and stir evenly.

[0037] 3. Grind the mixed raw materials through a pulverizer so that they can pass through a 1.5 mm screen.

[0038] 4. Move the pulverized material into the modulator, pass in 90°C steam for 5 minutes, and extrude and granulate at 95°C.

[0039] 5. Dry the feed pellets at 90°C.

[004...

Embodiment 2

[0042] A special compound feed for capons is prepared, comprising the following process steps:

[0043] 1. Weigh the component raw materials in the following weight percentages:

[0044] Corn 62%, soybean meal 26%, rapeseed meal 1%, fish meal 1%, rice bran 5%, fish oil 1%, stone powder 1.4%, calcium hydrogen phosphate 1.2%, multivitamin 0.032%, multimineral 0.1%, nutritional supplement 1.268%.

[0045] The nutritional supplement is composed of the following components in parts by weight: 27 lysine, 19 methionine, 8 threonine, 6 choline, 21 sodium bicarbonate, 16 table salt, and 3 enzyme preparations.

[0046] 2. Mix the raw materials of the above components at room temperature and stir evenly.

[0047] 3. Grind the mixed raw materials through a pulverizer so that they can pass through a 2.2mm screen.

[0048] 4. Move the pulverized material into the modulator, pass in 85°C steam for 5 minutes, and extrude and granulate at 100°C.

[0049] 5. Dry the feed pellets at 75°C.

...

Embodiment 3

[0052] A special compound feed for capons is prepared, comprising the following process steps:

[0053] 1. Weigh the component raw materials in the following weight percentages:

[0054] Corn 64%, soybean meal 24%, rapeseed meal 2%, fish meal 2%, rice bran 3%, fish oil 1%, stone powder 1.3%, calcium hydrogen phosphate 1.3%, multivitamin 0.027%, multimineral 0.13%, nutritional supplement 1.243%.

[0055] The nutritional supplement is composed of the following components in parts by weight: 30 lysine, 18 methionine, 7 threonine, 9 choline, 20 sodium bicarbonate, 15 salt, and 1 enzyme preparation.

[0056] 2. Mix the raw materials of the above components at room temperature and stir evenly.

[0057] 3. Grind the mixed raw materials through a pulverizer so that they can pass through a 2.0mm screen.

[0058] 4. Move the pulverized material into the modulator, pass in steam at 89°C for 4 minutes, and extrude and granulate at 92°C.

[0059] 4. Dry the feed pellets at 82°C.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com