Method for preparing nano delay composition for detonator

A delayed drug and nanotechnology, applied in the direction of explosives processing equipment, explosives, offensive equipment, etc., can solve problems such as failure to reach, crushing particle size limitation, loss of precision reduction, etc., to improve precision and stability, avoid vibration burning, improve The effect of combustion accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

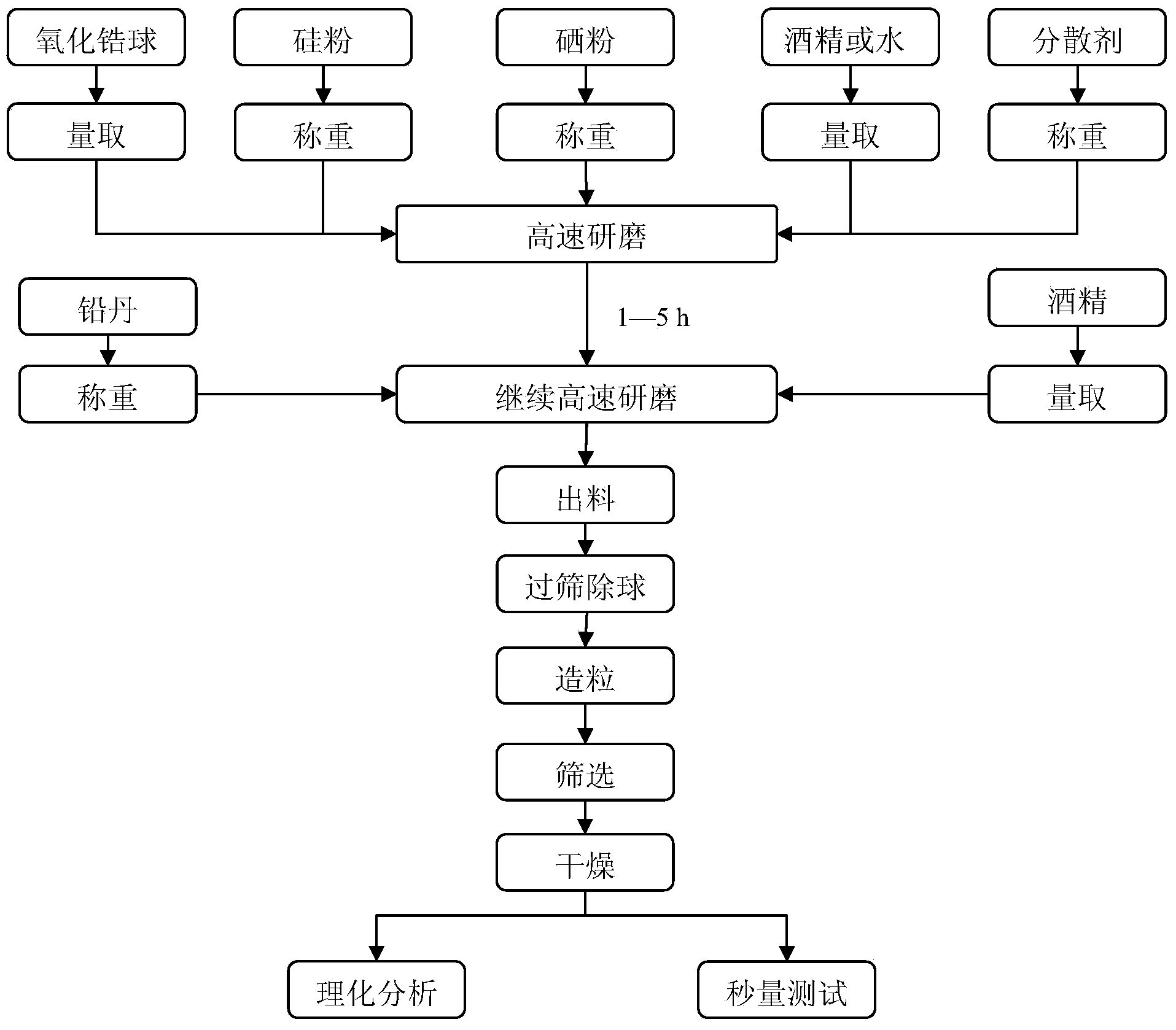

[0026] according to Figure 1 The preparation flow chart shown is for the preparation of nano-delay drug particles. First determine the formula and operating elements, red lead: silicon: selenium: German Lubrizol hyperdispersant Solsperse27000=93:7:3:1, using 0.8mm zirconia grinding balls, setting speed 2800r / min, total mixing The duration is 6h. The next step is to complete the operation according to the preset requirements. First, weigh 7.0000g of silicon powder, 3.0000g of selenium powder and 1.0000g of German Lubrizol hyperdispersant Solsperse27000, and then measure 90-120mL of alcohol and an appropriate amount of 0.8mm in diameter Zirconia balls, put them into a round stainless steel medicine tank with a volume of 250-750mL according to the method of adding balls first, then powder, and finally alcohol. At 30°C, start the grinder, set the speed at 2800r / min, stop the grinder after mixing the medicine for 3 hours, open the sealing cover, weigh 93.0000g of lead red into t...

Embodiment 2

[0028] according to Figure 1 The preparation flow chart shown is for the preparation of nano-delay drug particles. First determine the formula and operating elements, red lead: silicon: selenium: German Lubrizol hyperdispersant Solsperse27000=96:4:5:1, using 0.2mm zirconia grinding balls, setting speed 3300r / min, total mixing The duration is 6h. The next step is to complete the operation according to the preset requirements. First, weigh 4.0000g of silicon powder, 5.0000g of selenium powder and 1.0000g of German Lubrizol hyperdispersant Solsperse27000, and then measure 90-120mL of water and an appropriate amount of 0.2mm in diameter. Zirconia balls, put them into a circular stainless steel medicine tank with a volume of 250-750mL according to the method of adding balls first, then powder, and finally water. After 30°C, start the grinder, set the speed at 3300r / min, stop the grinder after mixing the medicine for 3 hours, open the sealing cover, weigh 96.0000g of red lead and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com