Dicyandiamide-modified flame-retardant polyether polyol preparation method, and prepared flame-retardant polyether polyol and application thereof

A polyether polyol, flame retardant polyether technology, applied in the application field of the polyurethane field, can solve the problems of large smoke, restriction, toxic gas, etc., and achieve the effects of low smoke generation, increased compatibility, and high oxygen index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

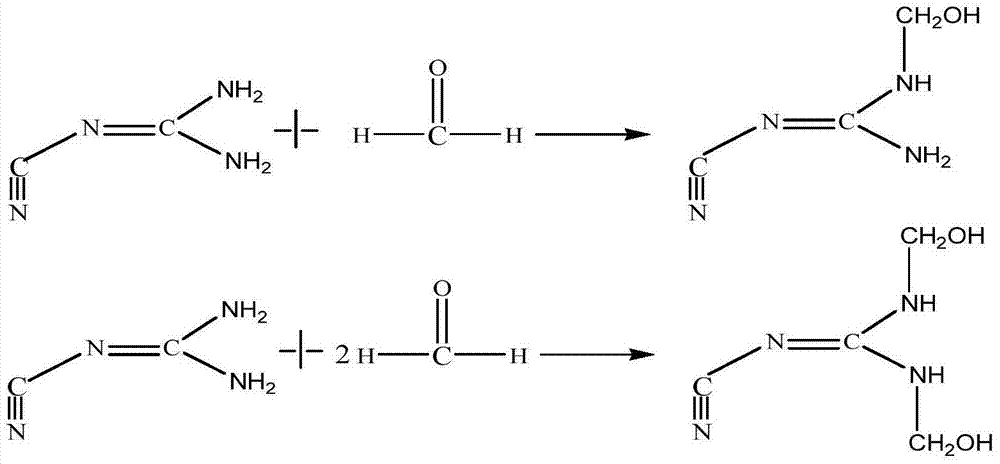

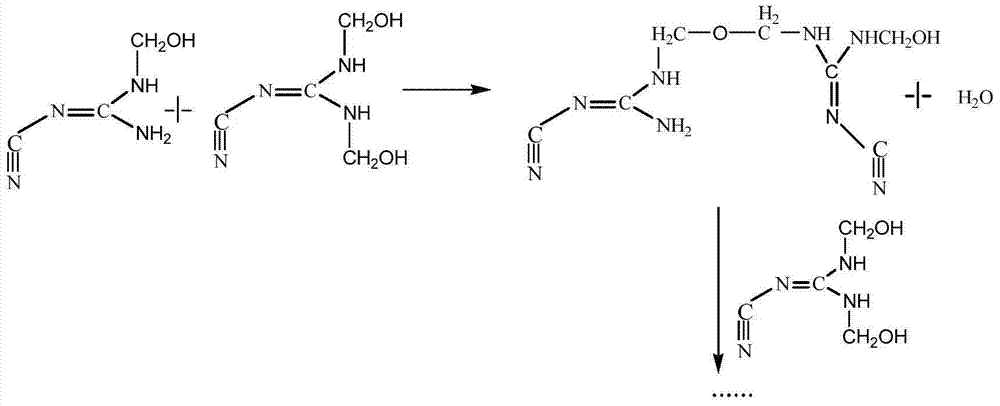

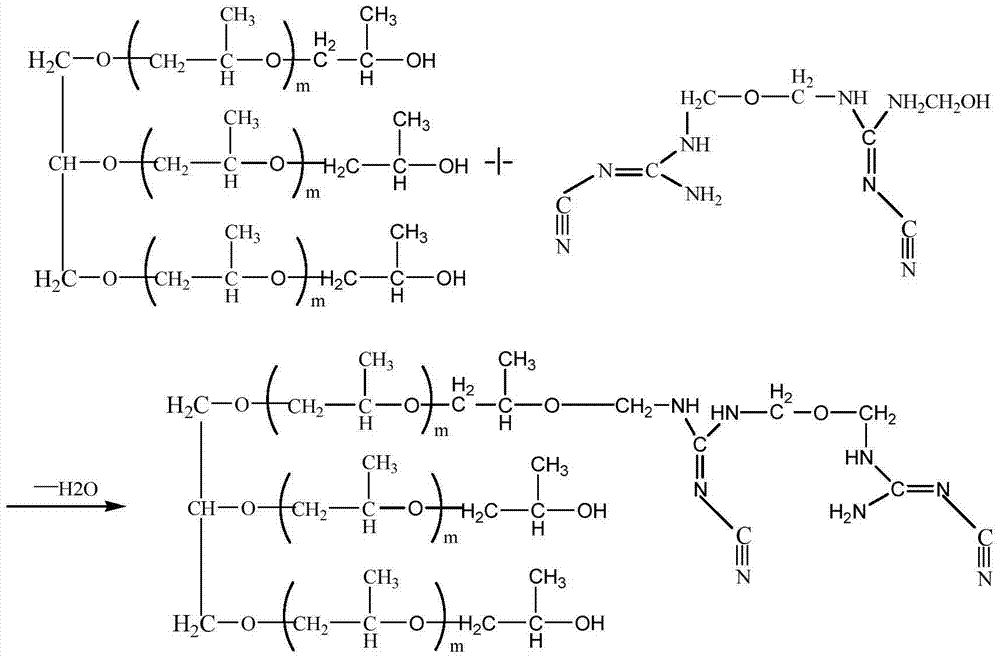

Method used

Image

Examples

Embodiment 1

[0036] Add 77g of formaldehyde aqueous solution (37%), 40g of dicyandiamide, and 19g of water into a three-necked flask equipped with a thermometer and a condenser, stir well, adjust the pH value to 10 with sodium methoxide, raise the temperature to 90°C, react for 4 hours, add poly Ether polyol (1618A provided by Jiangsu Zhongshan Chemical Co., Ltd., the same below) 176g, heat up to 100°C, react for 5h, then heat up to 140-150°C, vacuumize to -0.1MPa, and distill under reduced pressure for 1-2 hours to remove Remove small molecular substances and cool to obtain dicyandiamide-modified flame-retardant polyether polyol. The viscosity is 4000mPa.s, and the oxygen index of the flexible foam obtained by foaming the polyether is 28.

Embodiment 2

[0038] Add 77g (37%) formaldehyde aqueous solution (37%), 40g dicyandiamide, and 19g water into a three-necked flask equipped with a thermometer and a condenser, stir well, adjust the pH value to 9 with sodium methoxide, raise the temperature to 90°C, react for 4 hours, add poly Ether polyol (1618A) 217g, heat up to 100°C, react for 5h, heat up to 140-150°C, vacuumize to -0.1MPa, remove small molecules by distillation under reduced pressure for 1-2 hours, cool to obtain dicyandiamide modification flame retardant polyether polyol. The viscosity is 3000mPa.s, and the oxygen index of the flexible foam obtained by foaming the polyether is 26.

Embodiment 3

[0040]Add 77g (37%) of formaldehyde aqueous solution (37%), 40g of dicyandiamide, and 19g of water into a three-necked flask equipped with a thermometer and a condenser, stir well, adjust the pH value to 8 with sodium methoxide, raise the temperature to 95°C, react for 4 hours, add poly Ether polyol (1618A) 217g, heat up to 90°C, react for 5h, heat up to 140-150°C, evacuate to -0.1MPa, distill under reduced pressure for 1-2 hours to remove small molecular substances, cool to obtain dicyandiamide modified flame retardant polyether polyol. The viscosity is 3500mPa.s, and the oxygen index of the flexible foam obtained by foaming the polyether is 26.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com