Wear-resistant carbon fiber reinforced nylon 66 resin composition and preparation method thereof

A resin composition and carbon fiber technology, applied in the field of wear-resistant carbon fiber reinforced nylon 66 resin composition, can solve the problems of reduced tensile strength and low impact strength, and achieve good bending strength and modulus, impact strength and wear resistance. Increased, low coefficient of friction and wear effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Twin-screw extruder (Germany LEISTRITZ company, MICRO 27 type) barrel temperature is set to 250°C, 260°C, 270°C, 280°C, 285°C, 290°C, 290°C, 290°C from the feeding port to the die , 290°C, 285°C, set an opening in the fourth section from the feeding port to introduce continuous carbon fiber. Load the dry nylon 66 resin and nylon 6 resin mixture into the pellet weight loss feeder, the weight ratio of nylon 66 resin and nylon 6 resin is 95 / 5; put polytetrafluoroethylene resin +0.5 into the powder resin weight loss feeder %Antioxidant 1010 mixture (by weight percentage of the prepared resin composition, the same below). When the actual temperature of the barrel reaches the set temperature, turn on the twin-screw to make the speed reach 150 rpm, and then turn on the pellet resin weight loss feeder and powder resin weight loss feeder, so that the pellet resin feed rate is 2.55kg / h ( Calculated by polytetrafluoroethylene resin, the same below), the feeding speed of the powde...

Embodiment 2

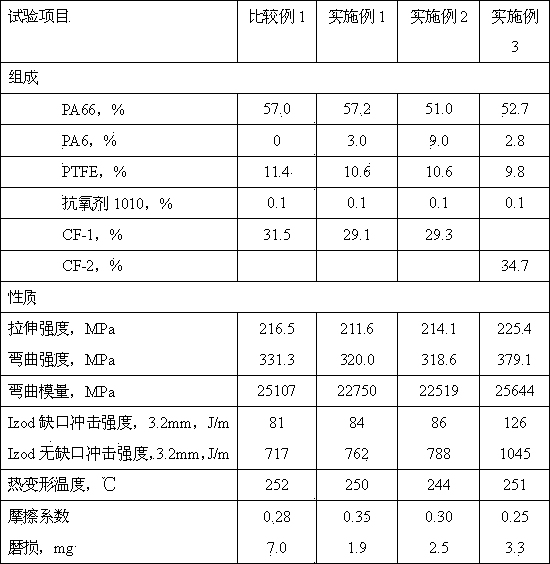

[0048] The barrel temperature setting of each section of the twin-screw extruder is the same as in Example 1, and the dry mixture of nylon 66 resin and nylon 6 resin is loaded into the pellet weight loss feeder, and the weight ratio of nylon 66 resin and nylon 6 resin is 85 / 15 ; Load polytetrafluoroethylene resin+0.5% antioxidant 1010 mixture in the powder resin weight loss feeder. When the actual temperature of the barrel reaches the set temperature, turn on the twin-screw to make the speed reach 150 rpm, so that the feeding speed of the pellet resin is 2.55kg / h, the feeding speed of the powder resin is 0.45kg / h, four strands of 12K carbon fiber -1 Introduce the barrel of the twin-screw extruder from the opening of the fourth section, mix the resin and carbon fiber, extrude into strips, and water-cool and pelletize to obtain a wear-resistant carbon fiber-reinforced nylon 66 resin composition. The properties of the composition tested after injection molding are shown in Table ...

Embodiment 3

[0051] The barrel temperature setting of each section of the twin-screw extruder is the same as in Example 1, and the dry mixture of nylon 66 resin and nylon 6 resin is loaded into the pellet weight loss feeder, and the weight ratio of nylon 66 resin and nylon 6 resin is 95 / 5 ; Load polytetrafluoroethylene resin+0.5% antioxidant 1010 mixture in the powder resin weight loss feeder. When the actual temperature of the barrel reaches the set temperature, turn on the twin-screw to make the speed reach 171 rpm, so that the feeding speed of the pellet resin is 2.55kg / h, the feeding speed of the powder resin is 0.45kg / h, four strands of 12K carbon fiber -2 Introduce the barrel of the twin-screw extruder from the opening of the fourth section, mix the resin and carbon fiber, extrude into strips, and water-cool and pelletize to obtain a wear-resistant carbon fiber reinforced nylon 66 resin composition. The properties of the composition tested after injection molding are shown in Table 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com