High-strength and anti-stripping elastomer modified asphalt waterproof coiled material and production process

A kind of asphalt waterproof membrane and production process technology, which is applied in the direction of asphalt layered products, layered products, building insulation materials, etc., can solve the problems of poor peeling strength of joints, water seepage at joints, lap joint failure, etc., and achieve improvement Effects of adhesion, improvement of stability and tensile strength, and improvement of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

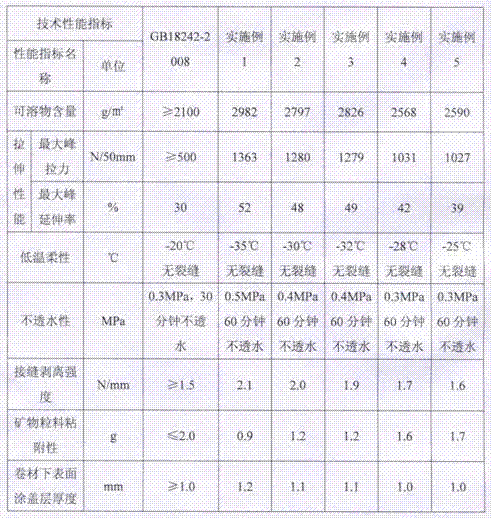

Examples

Embodiment 1

[0024] Embodiment 1: A high-strength peel-resistant elastomer-modified asphalt waterproofing membrane, the waterproofing membrane uses reinforced long-fiber polyester tires as the tire base, calculated by weight, and also includes:

[0025] 65 parts of petroleum pitch, nano TiO 2 5 parts of powder, 8 parts of styrene-butadiene-styrene block copolymer (SBS), 3 parts of C9 petroleum resin, 3 parts of HMD-2 series modified asphalt stabilizer, AMR series of asphalt anti-stripping agent 4 parts and 18 parts of 3000 mesh talcum powder.

[0026] When producing elastomer-modified asphalt waterproofing membranes, according to the above proportioning relationship, firstly measure the petroleum asphalt through the metering tank, then extract 65 parts of petroleum asphalt into the batching tank, and blend for 1.5 hours;

[0027] Then add 8 parts of styrene-butadiene-styrene block copolymer (SBS) and 3 parts of C9 petroleum resin, and blend for 0.5 hours;

[0028] Turn on the doub...

Embodiment 2

[0037] A high-strength peel-resistant elastomer-modified asphalt waterproofing membrane, the waterproofing membrane uses reinforced long-fiber polyester as the tire base, and by weight, it also includes: 65 parts of petroleum asphalt, nano-TiO 2 3 parts of powder, 6 parts of styrene-butadiene-styrene block copolymer (SBS), 5 parts of C9 petroleum resin, 2 parts of HMD-2 series modified asphalt stabilizer, AMR series of asphalt anti-stripping agent 6 parts and 15 parts of talcum powder of 3000 meshes, and produce according to the production process of preparing high-strength peel-resistant elastomer modified asphalt waterproofing membrane described in Example 1 to prepare high-strength peel-resistant elastomer-modified asphalt waterproof materials.

Embodiment 3

[0039] A high-strength peel-resistant elastomer-modified asphalt waterproofing membrane, the waterproofing membrane uses reinforced long-fiber polyester as the tire base, and by weight, it also includes: 65 parts of petroleum asphalt, nano-TiO 2 6 parts of powder, 10 parts of styrene-butadiene-styrene block copolymer (SBS), 1 part of C9 petroleum resin, 5 parts of HMD-2 series modified asphalt stabilizer, AMR series of asphalt anti-stripping agent 2 parts and 20 parts of 3000 mesh talcum powder, and according to the production process of preparing high-strength peel-resistant elastomer modified asphalt waterproof membrane described in Example 1, produce high-strength peel-resistant elastomer modified asphalt waterproof materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com