Liquid injection and suction method for cell slide-making dyeing machine and device thereof

A cell preparation and dyeing machine technology, applied in the preparation of test samples, etc., can solve problems such as affecting the diagnosis of pathologists, inability to stain cells, and changes in component content, achieve easy implementation and operation, avoid waste liquid residue, improve The effect of positive rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

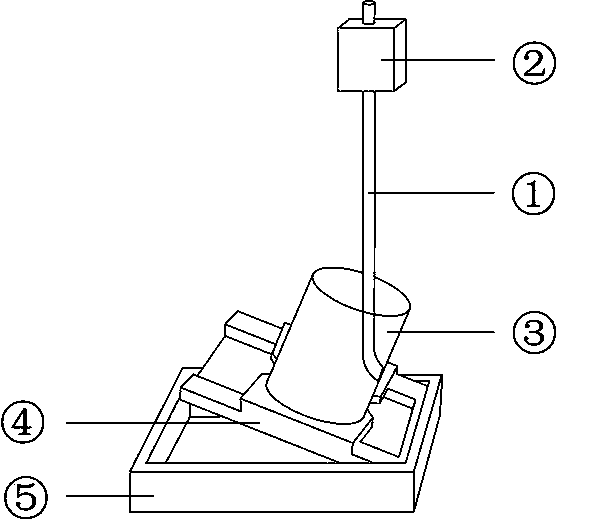

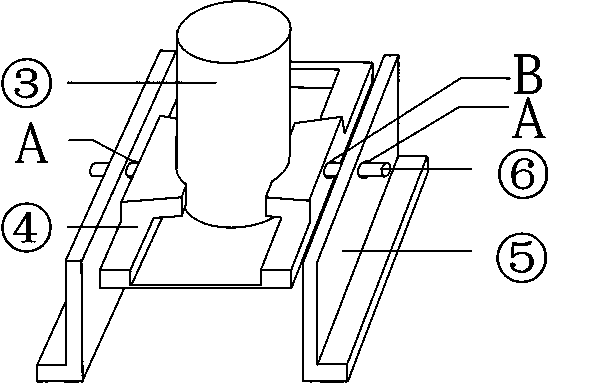

[0020] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0021] A method for injecting and absorbing liquid for a cell staining machine, characterized in that it comprises the following steps:

[0022] 1) Through the injection tube on the cell staining machine, extract the amount required for detection from the body fluid specimen placed in the sampling bottle and inject it on the glass slide close to the side of the tube wall, which is a one-time injection. Next, form a thin layer of cells on the glass slide; when injecting liquid, tilt the glass slide to the side of the round tube wall close to the injection tube;

[0023] 2) Use the pipette on the cell staining machine to suck up the remaining waste liquid; when sucking up the remaining waste liquid, tilt the glass slide to the side of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com