Long-period fiber bragg grating manufacturing method based on ink-jet printing technology

A technology of optical fiber grating and inkjet printing, which is applied in clad optical fiber, optical waveguide light guide, photoplate-making process coating equipment, etc., can solve the problems of poor stability, complex structure, large volume of optical fiber grating, etc., and achieve good consistency, The production process is simple and the production cost is reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

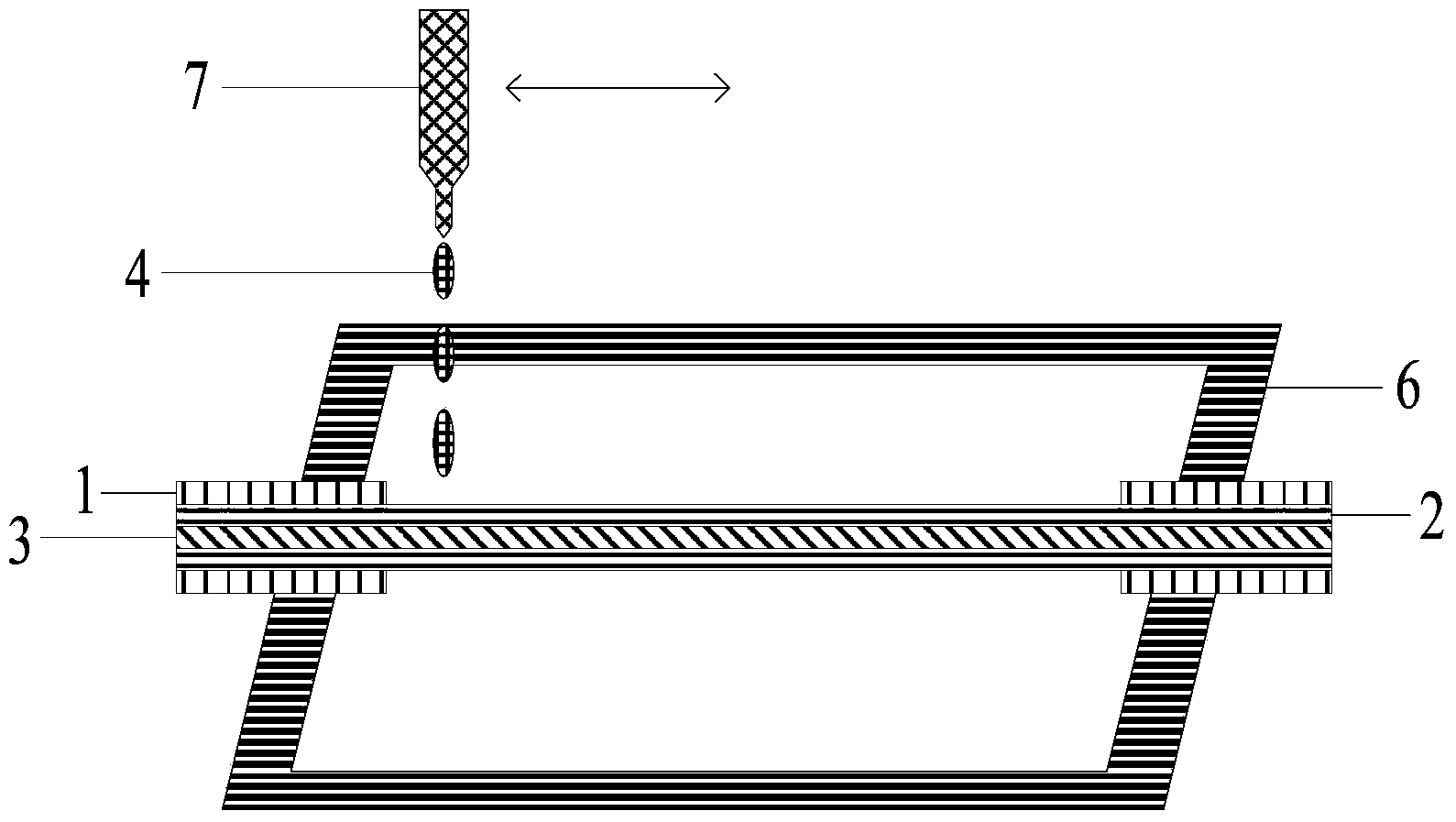

[0021] The implementation steps of a long-period fiber grating manufacturing method based on inkjet printing technology in this embodiment are as follows:

[0022] 1. Use fiber strippers to peel off the fiber coating layer 1 in the writing area of the photosensitive fiber grating with a length of 2cm, so that the fiber cladding 2 is exposed, and wipe the surface of the fiber cladding 2 clean with alcohol. The length and position of the writing area can be selected as required.

[0023] 2. Fix the clean photosensitive optical fiber on the optical fiber holder 6;

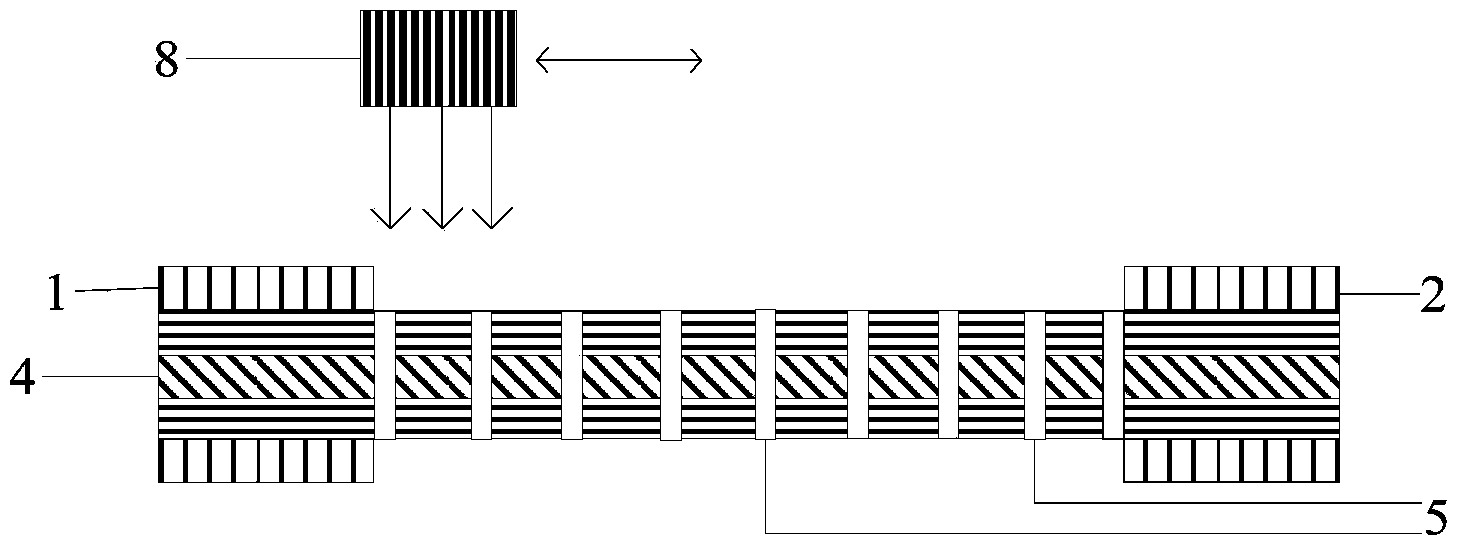

[0024] 3. Place the fixed photosensitive optical fiber on the platform of the inkjet printing device 7; use the inkjet printing technology to spray the photoresist 4 on the surface of the exposed optical fiber cladding 2, and coat the photoresist with periodic intervals. Layer 5 covers the optical fiber cladding 2, and then the photoresist coating 5 is dried. Specific steps are as follows:

[0025] (a) Use RZR-31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com