A method for harmless treatment of chromium-containing waste coexisting with multiple metals

A harmless treatment and multi-metal technology, applied in the direction of chromium oxide/hydrate, iron oxide, chromium trioxide, etc., can solve the problems of wasting resources, increasing environmental pressure, etc., and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

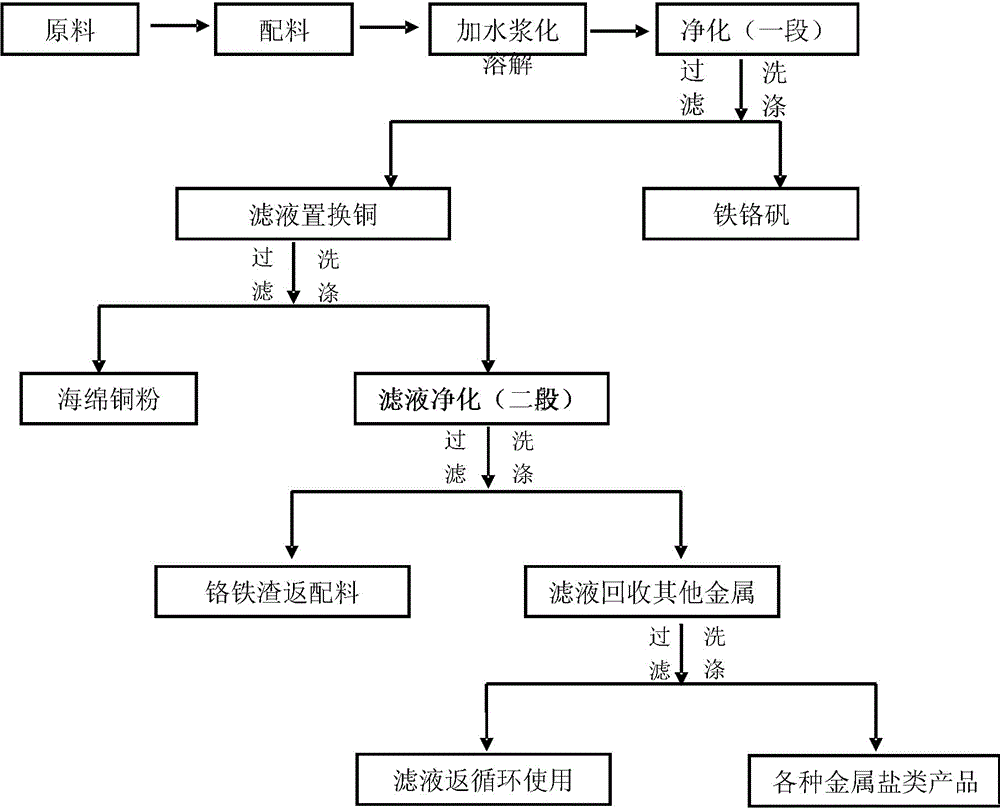

[0020] The flow chart of the harmless treatment method of chromium-containing waste with coexistence of multiple metals is as follows figure 1 As shown, specifically:

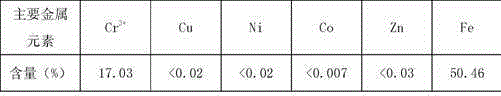

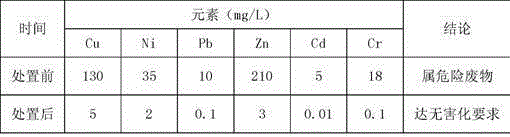

[0021] Ingredients for the chromium-containing waste materials HW17, HW21, and HW22 that coexist with polymetallic materials (the ingredients mean that before the raw materials are mixed with water, zero-valent iron and other ingredients are added to the raw materials to meet the requirements of hexavalent chromium and zero-valent iron. Ratio, to facilitate the subsequent process), make hexavalent chromium: zero-valent iron=1:1.5, Fe:Cr=2.5-3.5:1 (the ratio of total iron to total chromium, including hexavalent chromium and zero-valent iron); The mixed slurry is prepared by mixing the mixed chromium-containing waste materials HW17, HW21, HW22 and water at a weight ratio of 1:3-5, and then adding 98% concentrated sulfuric acid to the mixed slurry, and the temperature is controlled <60 ℃, to pH1.0-1.5 of the mixed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com