Method for preparing nano hydroxyapatite

A technology of nano-hydroxyapatite and powder, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of low product output, consumption, and poor uniformity, and achieve reduced feeding time, cheap and easy-to-obtain raw materials, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] In the first step, weigh 30.9g (CaNO 3 ) 2 · 4H 2 O and 13.2g (NH 4 ) 2 HPO 4 The powders were respectively dissolved in deionized water to prepare 0.2mol / L (CaNO 3 ) 2 · 4H 2 O solution and 0.2mol / L (NH 4 ) 2 HPO 4 solution.

[0018] In the second step, the (NH 4 ) 2 HPO 4 Added dropwise to (CaNO 3 ) 2 · 4H 2 O, using PEG2000 as a dispersant, and adjusting the pH to 10 with ammonia water.

[0019] The third step is aging for 24 h after the dropwise addition. The obtained product was centrifuged at 10,000 r / min for 20 min, and washed with water three times to obtain nano-hydroxyapatite.

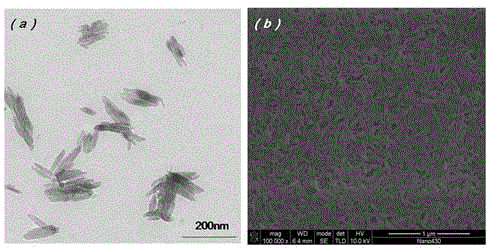

[0020] The microscopic morphology of the prepared nano-hydroxyapatite is rod-shaped and well dispersed; the length is about 120nm and the width is about 30nm (the aspect ratio is about (5:1).

Embodiment 2

[0022] In the first step, weigh 8.856g (CaNO 3 ) 2 · 4H 2 O and 2.971g (NH 4 ) 2 HPO 4 The powders were respectively dissolved in deionized water to prepare 0.2mol / L (CaNO 3 ) 2 · 4H 2 O solution and 0.2mol / L (NH 4 ) 2 HPO 4 solution.

[0023] In the second step, the (NH 4 ) 2 HPO 4 Added dropwise to (CaNO 3 ) 2 · 4H 2 O, using PEG2000 as a dispersant, and adjusting the pH to 10 with ammonia water.

[0024] The third step is aging for 24 h after the dropwise addition. The obtained product was centrifuged at 10,000 r / min for 20 min, and washed with water three times to obtain nano-hydroxyapatite.

[0025] The microscopic shape is needle-like, about 80nm in length.

Embodiment 3

[0027] In the first step, at room temperature, 9.54g of (CaNO 3 ) 2 · 4H 2 O was added into 80mL polyethylene glycol aqueous solution (4w%t) dissolved in advance.

[0028] In the second step, configure 0.8mol / L (NH 4 ) 2 HPO 4 Solution 30mL, while adjusting the pH value at 10 with ammonia water during the dropwise addition.

[0029] The third step is to continue stirring for 30 minutes after the dropwise addition and aging for 24 hours.

[0030] The microscopic morphology of the prepared nano-hydroxyapatite is needle-like, and the length is about 60nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com