Two phase compound microwave dielectric ceramic having medium dielectric constant, and preparation method thereof

A microwave dielectric ceramic and electrical constant technology, applied in the field of information functional material science, can solve the problems of low dielectric constant, large shift of resonant frequency temperature coefficient, high price, etc., and achieve excellent dielectric properties, low sintering temperature, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

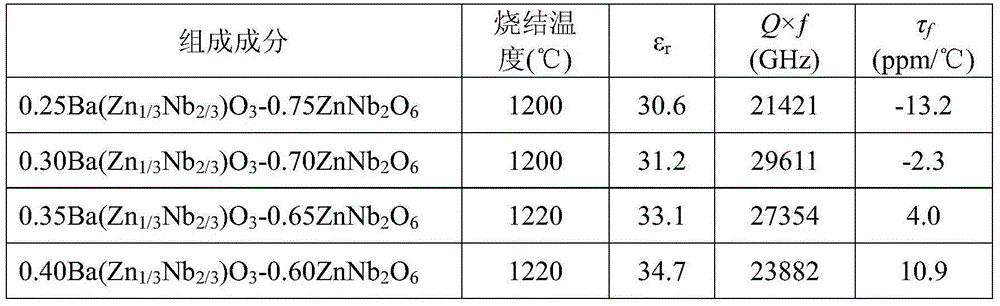

Examples

Embodiment 1

[0016] This embodiment is a microwave dielectric ceramic. The microwave dielectric ceramics are ZnO, Nb with a purity of 99.9% respectively 2 o 5 and BaCO 3 As the starting material, according to xBa(Zn 1 / 3 Nb 2 / 3 )O 3 +(1-x)ZnNb 2 o 6 (wherein x=0.25, x is the stoichiometric dosage ratio batching of mole percent).

[0017] This embodiment also proposes a method for preparing the microwave dielectric ceramic, and its specific preparation steps are:

[0018] (1) ZnO and Nb with a purity of 99.99% 2 o 5 Weigh according to the molar ratio of 1:1, and the weighed ZnO and Nb 2 o 5 Put it in a nylon ball mill jar, add absolute ethanol according to the mass ratio of powder and ethanol at 1:1, mill on a ball mill for 12 hours, then dry at 50°C for 6 hours, grind, and pre-fire to make ZnNb 2 o 6 , the calcining temperature is 1000℃, and the calcining time is 2h. After calcining, ZnNb is obtained by secondary ball milling and drying. 2 o 6 Pre-burned powder;

[0019] (2)...

Embodiment 2

[0025] This embodiment is a microwave dielectric ceramic. The microwave dielectric ceramics are ZnO, Nb with a purity of 99.9% respectively 2 o 5 and BaCO 3 As the starting material, according to xBa(Zn 1 / 3 Nb 2 / 3 )O 3 +(1-x)ZnNb 2 o 6 (wherein x=0.30, x is the stoichiometric dosage ratio batching of mole percent).

[0026] This embodiment also proposes a method for preparing the microwave dielectric ceramic, and its specific preparation steps are:

[0027] (1) ZnO and Nb with a purity of 99.99% 2 o 5 Weigh according to the molar ratio of 1:1, and the weighed ZnO and Nb 2 o 5 Put it in a nylon ball mill jar, add absolute ethanol according to the mass ratio of powder and ethanol at 1:1, mill on a ball mill for 12 hours, then dry at 50°C for 6 hours, grind, and pre-fire to make ZnNb 2 o 6 , the calcining temperature is 1000℃, and the calcining time is 2h. After calcining, ZnNb is obtained by secondary ball milling and drying. 2 o 6 Pre-burned powder;

[0028] (2)...

Embodiment 3

[0034] This embodiment is a microwave dielectric ceramic. The microwave dielectric ceramics are ZnO, Nb with a purity of 99.9% respectively 2 o 5 and BaCO 3 As the starting material, according to xBa(Zn 1 / 3 Nb 2 / 3 )O 3 +(1-x)ZnNb 2 o 6 (wherein x=0.35, x is the stoichiometric dosage ratio batching of mole percent).

[0035] This embodiment also proposes a method for preparing the microwave dielectric ceramic, and its specific preparation steps are:

[0036] (1) ZnO and Nb with a purity of 99.99% 2 o 5 Weigh according to the molar ratio of 1:1, and the weighed ZnO and Nb 2 o 5 Put it in a nylon ball mill jar, add absolute ethanol according to the mass ratio of powder and ethanol at 1:1, mill on a ball mill for 12 hours, then dry at 50°C for 6 hours, grind, and pre-fire to make ZnNb 2 o 6 , the calcining temperature is 1000℃, and the calcining time is 2h. After calcining, ZnNb is obtained by secondary ball milling and drying. 2 o 6 Pre-burned powder;

[0037] (2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com