High-heat-resisting ethylene acrylate rubber composition for hose of passenger car turbocharging system

A turbocharging system, ethylene acrylate technology, applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of the most expensive, difficult to control processability, and inability to make the best use of everything

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with a large number of practical tests, the present invention will be further illustrated.

[0014]

[0015]

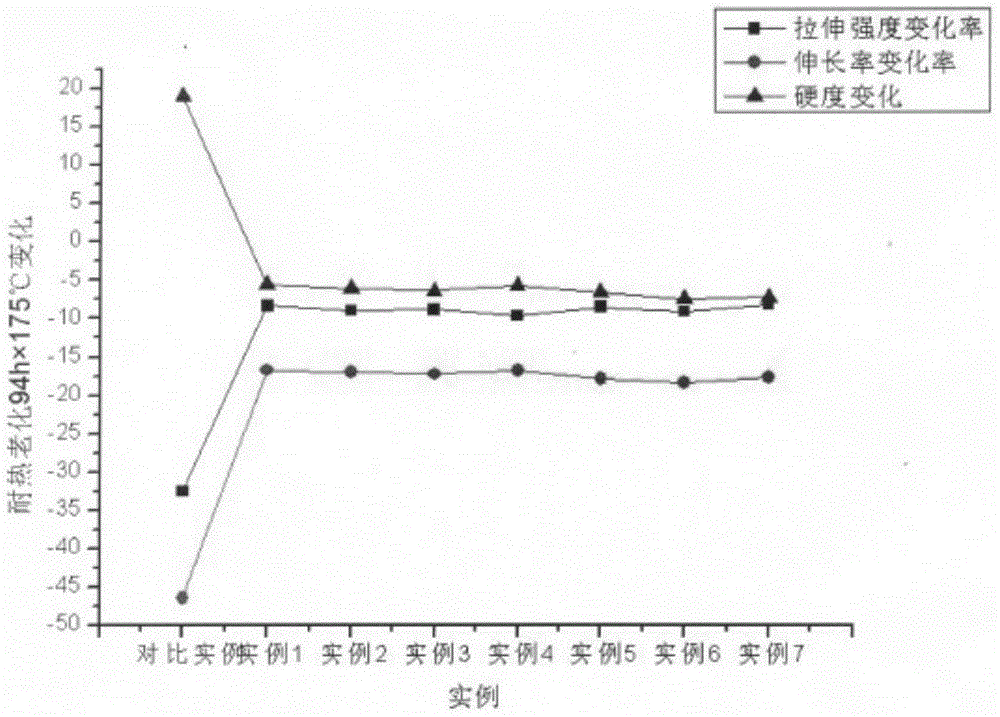

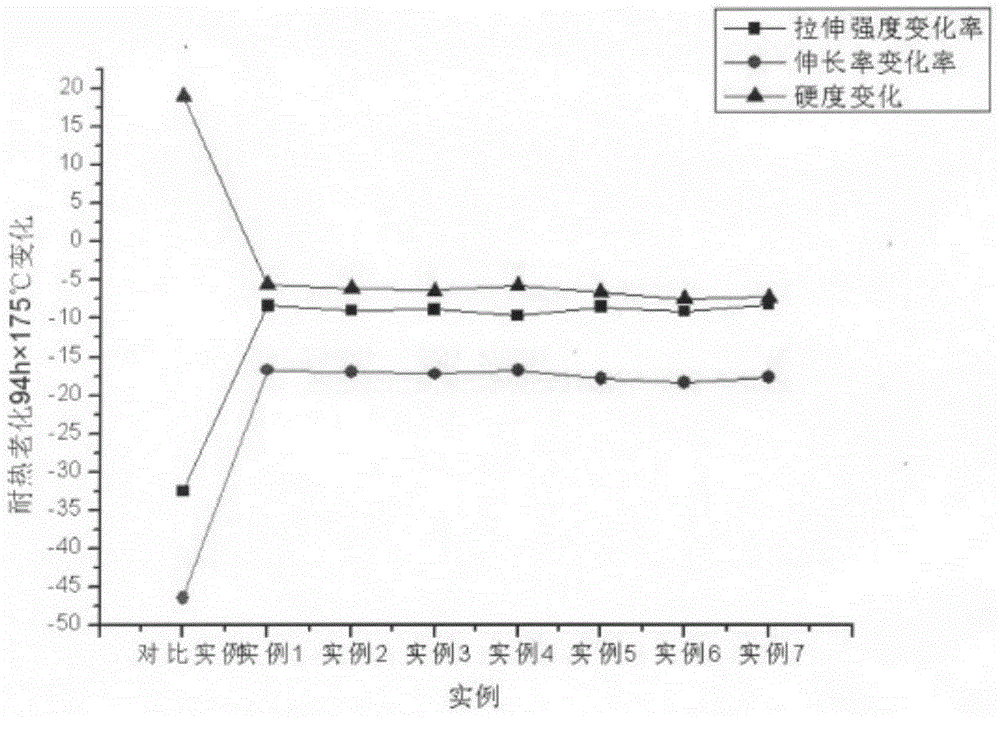

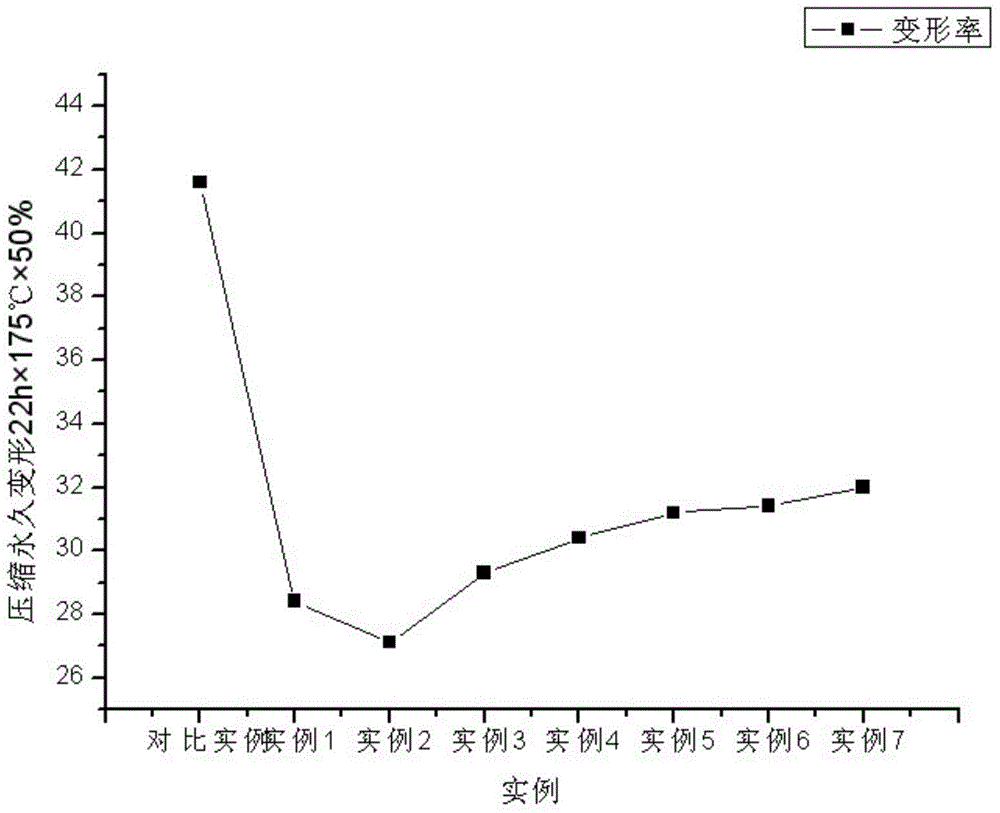

[0016] The rubber composition of the present invention lies in the specifications of rubber and the cooperative use with reinforcing carbon black N550, low-volatility polyether / polyester hybrid plasticizer TP-759, vulcanizing agent DIAK1#, and can quickly extrude carbon black N550 is easy to extrude and easy to produce while playing a reinforcing role. The plasticizer TP-759 better guarantees the production process. The vulcanizing agent DIAK1# can guarantee the compression set within a certain range. Through the DOE formula design, a large number of summaries are summarized According to the test data, it is found that Ultra HT is far superior to Vamac IP in heat resistance, oil resistance and compression set, as shown in Figure 1, figure 2 , image 3 shown.

[0017] To sum up, the rubber composition hose of the present invention ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com