High manganese steel for automobiles and manufacturing method thereof

A manufacturing method and technology of high manganese steel, applied in the field of iron and steel metallurgical materials, can solve the problems of reducing the hot rolling performance of steel plates, increasing the number of stacking faults, reducing the stacking fault energy of alloys, etc., to achieve high yield strength and plasticity, improve yield strength and The effect of tensile strength and safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

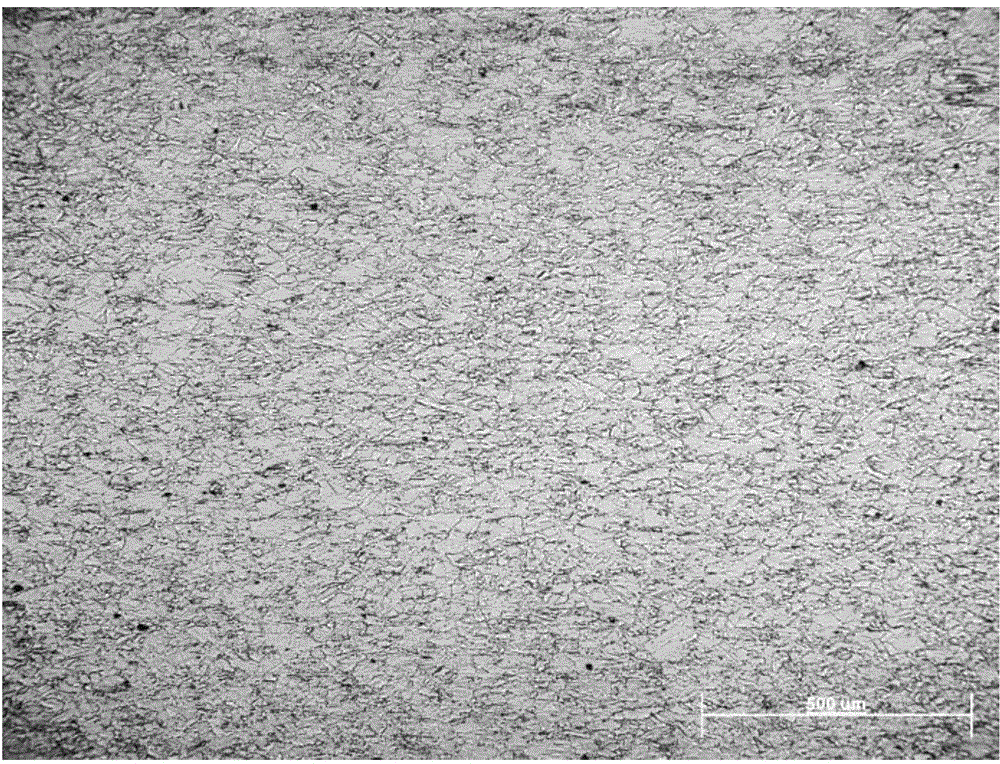

Image

Examples

Embodiment 1

[0038] A kind of high manganese steel for automobile, its chemical composition and weight percentage content are: C: 0.58%; Si: 0.006%; Mn: 23.8%; P: 0.008%; Nb: 0.52%; Als: 0.0029%; S: 0.006 %; N: 0.0017%, the rest is Fe and unavoidable impurities.

[0039] The manufacturing method of above-mentioned steel, comprises the following steps:

[0040] 1) Smelting and continuous casting into billets;

[0041] 2) Heating: heating the continuous casting slab to 1270°C;

[0042] 3) Rough rolling: rough rolling at 1055°C;

[0043] 4) Finish rolling: control the finish rolling temperature to 920°C;

[0044] 5) Coiling: coiling at 700°C;

[0045] 6) Cold rolling: cold rolling is carried out under the condition of controlling the total reduction rate to 75%;

[0046] 7) Continuous annealing: control the continuous annealing temperature at 830°C;

[0047] 8) Finished and ready for use (flattened elongation rate is 0.6%).

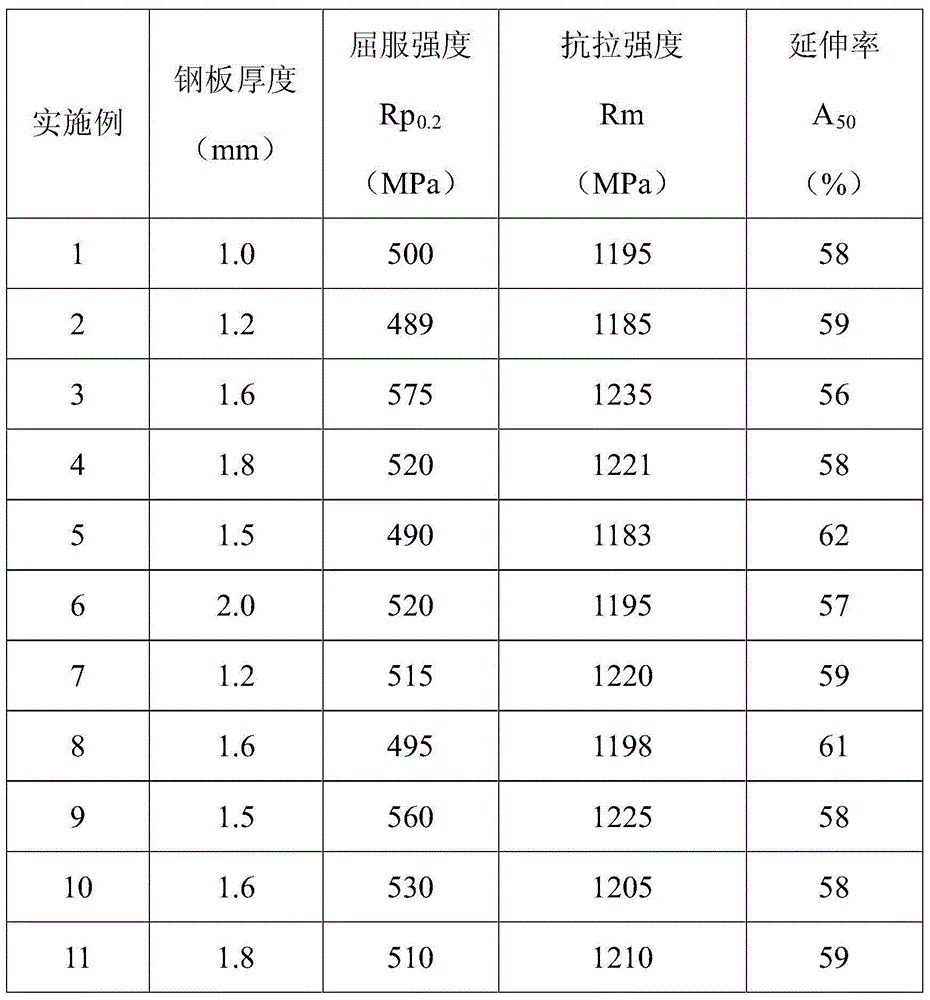

[0048] The mechanical properties of the obtained steel are s...

Embodiment 2

[0050] A kind of high manganese steel for automobile, its chemical composition and weight percentage content are: C: 0.55%; Si: 0.008%; Mn: 23.8%; P: 0.014%; Nb: 0.46%; Als: 0.03%; S: 0.008 %; N: 0.002%, the rest is Fe and unavoidable impurities.

[0051] The manufacturing method of above-mentioned steel, comprises the following steps:

[0052] 1) Smelting and continuous casting into billets;

[0053] 2) Heating: heating the continuous casting slab to 1220°C;

[0054] 3) Rough rolling: rough rolling at 1055°C;

[0055] 4) Finish rolling: control the finish rolling temperature to 930°C;

[0056] 5) Coiling: coiling at 700°C;

[0057] 6) Cold rolling: cold rolling is carried out under the condition of controlling the total reduction rate to 80%;

[0058] 7) Continuous annealing: control the continuous annealing temperature at 800°C;

[0059] 8) Finish and set aside.

[0060] The mechanical properties of the obtained steel are listed in Table 1.

Embodiment 3

[0062] A kind of high manganese steel for automobiles, its chemical composition and weight percentage content are: C: 0.62%; Si: 0.009%; Mn: 24.4%; P: 0.01%; Nb: 0.45%; Als: 0.02%; S: 0.009 %; N: 0.0029%, the rest is Fe and unavoidable impurities.

[0063] The manufacturing method of above-mentioned steel, comprises the following steps:

[0064] 1) Smelting and continuous casting into billets;

[0065] 2) Heating: heating the continuous casting slab to 1280°C;

[0066] 3) Rough rolling: rough rolling at 1070°C;

[0067] 4) Finish rolling: control the finish rolling temperature to 910°C;

[0068] 5) Coiling: coiling at 680°C;

[0069] 6) Cold rolling: Cold rolling is carried out under the condition of controlling the total reduction rate to 67%;

[0070] 7) Continuous annealing: control the continuous annealing temperature to 850°C;

[0071] 8) Finish and set aside.

[0072] The mechanical properties of the obtained steel are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com